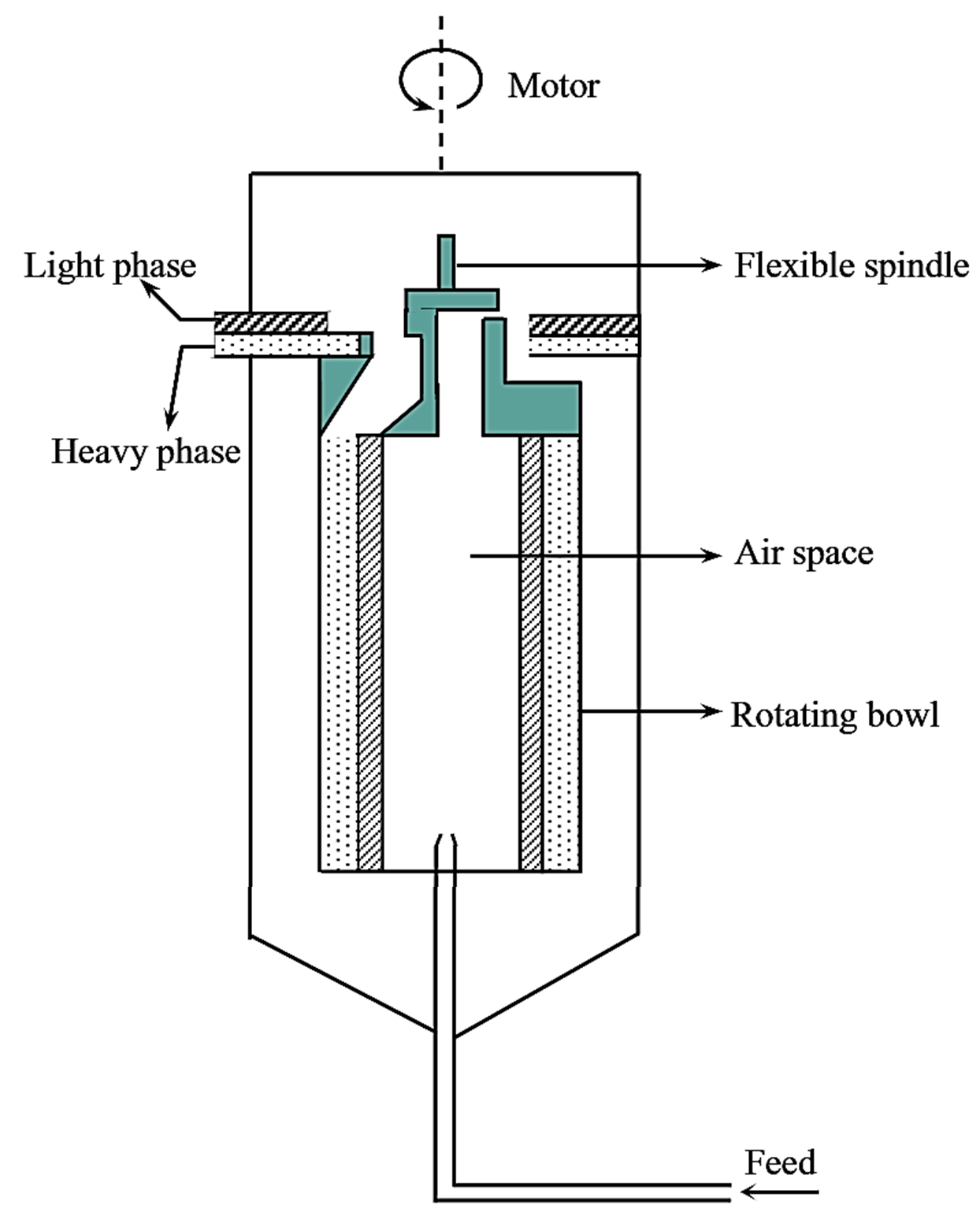

Figure 1: Super Centrifuge.

Working Principle of Super Centrifuge

It works on the principle of sedimentation. It enables the separation of two immiscible liquid based on the difference in their densities. Due to the centrifugal force, the heavier liquid is thrown against the wall, while the lighter liquid forms the inner layer (near centre).

Construction of Super Centrifuge

- It consists of a hollow cylindrical bowl.

- The diameter ranges from is 1.75 – 5 inches with a length of 9-30 inches.

- It is attached to a flexible spindle at the top and to a loose-fit bushing at the bottom.

- The bowl is mounted in such a way that it can be rotated on its longitudinal axis.

- The liquid which is to be separated is introduced into the bowl under pressure through the feed inlet.

- Two outlet provisions are made at different heights at the top of the centrifuge.

- Modified weirs can be used for simultaneous recovery’ of the separated liquids.

Working of Super Centrifuge

- Feed is admitted at the bottom of the centrifuge through a feed nozzle under vacuum system.

- Power is supplied to the entire system to rotate it in vertical manner.

- The speed of rotation is up to 2000 rpm.

- By the centrifugation process, the heavier liquid phase is thrown out against the wall, while the lighter liquid settles as an inner layer.

- Hydraulic balance maintains the liquid-liquid interface (neutral zone) between two immiscible liquids.

- Separated liquid phases are collected from the top of the bowl through outlets with the help of modified weirs.

- Simultaneous removal of two immiscible liquids is possible enabling continuous operation.

Advantages of Super Centrifuge

- Efficiency of separation is high.

Disadvantages of Super Centrifuge

- Output is limited.

Modifications of Super Centrifuge

Tubular bowl centrifuge

- Used for the separation of solids and liquids when solid content is low.

- From a suspension, the solids get accumulated on the wall, while the liquid can be clarified from the top by centrifugal force.

- If necessary, the deposited solid is collected at regular intervals.

- Limited capacity.

Applications of Super Centrifuge

- These are widely employed in food, biochemical and pharmaceutical industry.

- Used to separate phases of emulsions.

- Clarification of liquid can also be carried out.