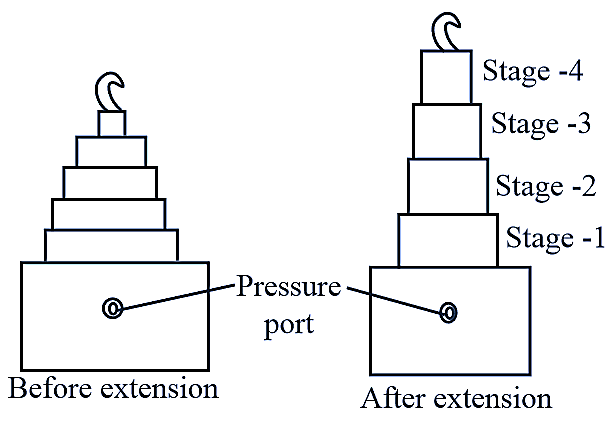

Telescopic Cylinder is a special type of hydraulic cylinder. It is used in applications where long extension strokes and small return strokes are required. Extension of this cylinder takes place in stages and every individual is provided with a stage sleeve which is fitted inside the previous stage.

Working Principle & Construction of Telescopic Cylinder

Figure 1: Telescopic Cylinder

The telescopic cylinder works on the displacement principle. It consists of two or more tubes depending on the number of stages, i.e., each stage consists of a tube. Tubes are in progressively decreasing diameters and they are fitting into each other to form a nest of tubes. Bearing rings support each tube and grooves are provided in the tubes for the flow of fluid. The bearing assembly at front portion of a each tube consists of wiper rings and seals. The movement of each stage is controlled by a stop ring to avoid separation of tubes. The sleeve extend from larger diameter to small diameter. When oil pressure is applied at pressure port, the cylinder starts to extend. At this instant, all sleeves has movement. Stop ring avoids the further movement of larger sleeve first, when it reaches extreme limit of its stroke. The remaining sleeves move together as long as second outemost sleeve is restricted from further extension at its stroke limit. Similarly, extension of all the sleeves occur. The sleeve of smallest diameter (called plunger) of all, makes the final extension. In this cylinder, when each successive stage reaches limit of its stroke, load lifting capacity will decrease and operation speed will increase. For a given specific pressure and flow rate at input respectively.

Applications of Telescopic Cylinder

Telescopic cylinders are generally used, where longer working strokes are required in a short retracted casing. In automobiles such as tippers or dumpers uses a two or three stage telescopic cylinder for unloading the gravel. These type of cylinders also have applications in hydraulic cranes, fork lift trucks, etc.