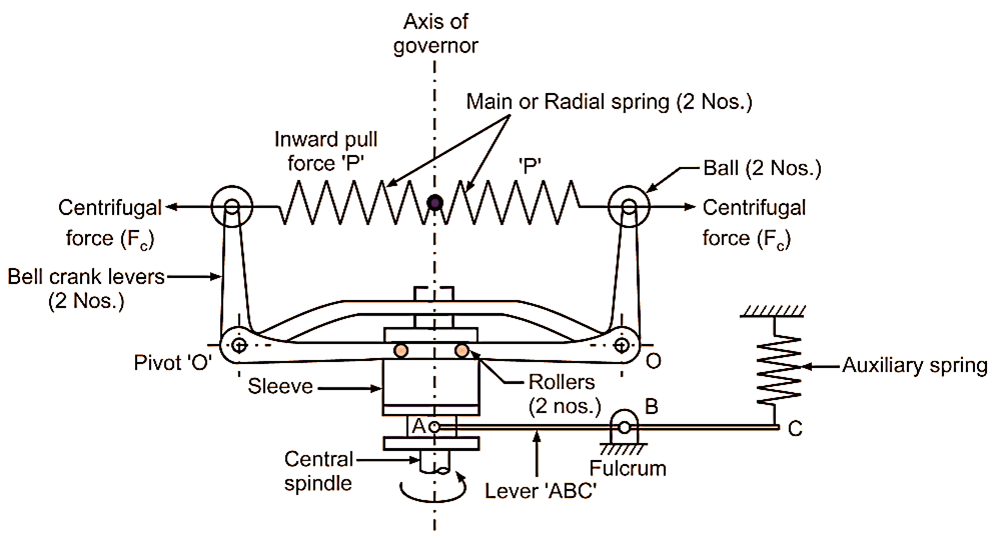

Wilson Hartnell Governor is a spring-loaded type of governor, in which, balls are connected by springs in tension. Here, two bell crank levers are pivoted at the ends of vertical and horizontal arms. The fly-balls are attached to the ends of vertical arms of bell crank levers. Horizontal arms of bell crank levers carry two rollers at their ends. The bell crank levers rotate with the rotating spindle about governor axis. The two balls are connected by two radial or main springs arranged symmetrically on either side of the sleeve . The radial or main springs control the centrifugal force. Usually the initial tension in the main springs is not adjustable, so an adjustable auxiliary spring is provided. It is used to adjust the mean speed for a given radius of rotation. Auxiliary spring is connected to one end of lever and the other end of lever fits into the groove in the sleeve. The auxiliary spring tends to keep the sleeve down. The lever is pivoted at fulcrum (i.e. point ‘B’) as shown in Fig. 1.

Fig. 1: Wilson-Hartnell Governor

Working of Wilson Hartnell Governor

When the load on the engine decreases, then the radius of rotation of flywheel increases due to increase in speed, the balls try to fly out (move away from the governor axis). The main springs exert an inward pull force on the balls and the sleeve moves upwards closing the throttle valve to decrease the speed. Exactly opposite phenomenon is observed, if load on the engine increases.