Thermostatic expansion valve (TEV) is the most commonly used expansion device in commercial and industrial refrigeration systems.

Working Principle of Thermostatic Expansion Valve

Thermostatic expansion valve maintains a constant superheat of the vapour refrigerant at the end of the evaporator coil, by controlling the flow of liquid refrigerant through the evaporator. Thus, its operation is based on the principle of constant degree of superheat at the evaporator outlet by controlling the flow of liquid refrigerant through the evaporator. Therefore, it is called as Constant superheat valve.

Construction of Thermostatic Expansion Valve

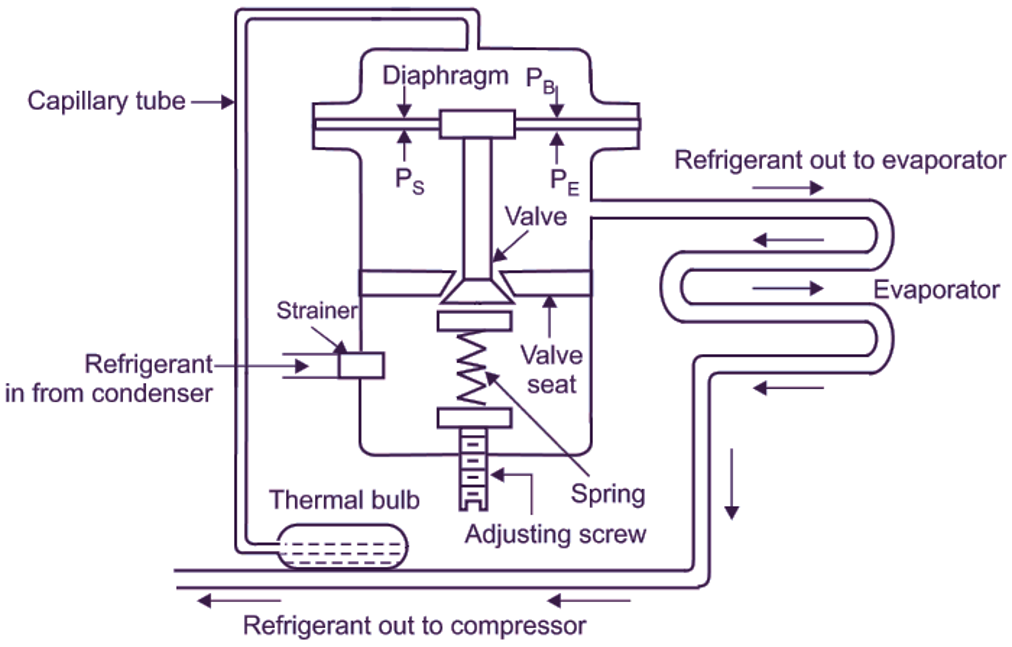

Fig. 1: Thermostatic expansion valve.

Thermostatic expansion valve consists of a needle valve and a seat, a metallic diaphragm, a spring and an adjusting screw. Refer Fig. 1. In addition to this, it has a feeler or thermal bulb, which is mounted on the suction line near the outlet of the evaporator coil. The feeler bulb is partly filled with the same liquid refrigerant as used in the refrigeration system. The opening and closing of the valve depends upon the following forces acting on the diaphragm.

- The spring pressure (PS) acting vertically upwards on the bottom side of daphragm,

- The evaporator pressure (PE) acting vertically upwards on the bottom side of diaphragm, and

- The feeler bu b pressure (PB) acting vertically downwards on the top side of diaphragm.

Since the feeler bulb is installed on the suction line, therefore it will be at the same temperature as the refrigerant at the point of surface contact. Any changes in the temperature of the refrigerant will cause a change in pressure in the feeler bulb, which will be transmitted to the top of the diaphragm. Under normal operating conditions, the feeler bulb pressure acting on the top side of diaphragm is balanced by spring pressure and evaporator pressure acting on the bottom side of the diaphragm. i.e.

PB = PS+ PE

The force tending to close the valve is dependent upon, (i) Spring pressure (PS) and (ii) Evaporator pressure (PE), which depends upon the saturation temperature of refrigerant in the evaporator coil. The force tending to open the valve depends upon the feeler bulb pressure (PB), which depends upon the temperature of refrigerant in the feeler bulb. Thus, the operation of valve is control ed by the difference between the two temperatures (i.e. saturation temperature and feeler bulb temperature). This temperature difference is called as degree of superheat. The degree of superheat of the vapour refrigerant leaving the evaporator depends upon the initial setting of spring tension, which can be changed with the help of spring adjusting screw. When the valve is set for certain superheat, then it maintains those settings under all load conditions on the evaporator.

Working of Thermostatic Expansion Valve

When refrigeration load on the evaporator increases

If refrigeration load on the evaporator increases, it causes the liquid refrigerant to boil faster in the evaporator coil. The temperature of feeler bulb increases due to early vapourization of liquid refrigerant. Thus, the feeler bulb pressure increases and this pressure is transmitted through a small diameter tube (also known as capillary tube) to the diaphragm. The diaphragm moves downwards and opens the valve to admit more quantity of liquid refrigerant to the evaporator. This continues till the pressure equilibrium on the diaphragm is reached.

When refrigeration load on the evaporator decreases

On the other hand, when refrigeration load on the evaporator decreases, less amount of liquid refrigerant evaporates in the evaporator coil. The excess liquid refrigerant flows towards the evaporator outlet, which cools the feeler bulb. Due to this, the feeler bulb pressure decreases due to decrease in its temperature. The low feeler bulb pressure is transmitted through the capillary tube to the diaphragm and moves the diaphragm in upward direction. This reduces the opening of valve and thus, reduces the flow of liquid refrigerant to the evaporator. The evaporator pressure decreases due to reduced quantity of liquid refrigerant flowing to the evaporator. This continues till the evaporator pressure and the spring pressure maintains equilibrium with the feeler bulb pressure.

Functions performed by thermostatic expansion valve in a refrigerating system

Throttling action: The thermostatic valve, like any other valve, has a pressure drop across it. It separates the high pressure side from the low pressure side of the system.

Modulating action: It feeds the proper amount of liquid refrigerant in to evaporator. Neither, it dries the evaporator nor it floods evaporator with refrigerant.

Controlling action: It meets the need of changing loads. As the load on refrigeration system increases, the expansion valve modulates towards the wider opening position. When refrigeration load decreases, it acts in opposite manner.

Applications of Thermostatic Expansion Valve

Besides the capillary tube, the thermostatic expansion valve is used Widely in the refrigeration and air conditioning systems. Capillary tube is used in the small capacity systems like domestic appliances, whereas, the thermostatic expansion valve is used in commercial and industrial refrigeration systems of higher capacity. Thermostatic expansion valve is commonly used in,

- Industrial refrigeration plants.

- Commercial units such as supermarkets, freezers, ice maker machines.

- High capacity split air conditioners.

- Packaged air conditioners.

- Refrigerated containers.

- Heat pump systems.

- Transport refrigeration systems.

- Liquid chillers.

- Central air conditioners and many other systems.

Advantages of Thermostatic Expansion Valve

- TEV maintains the flow of the refrigerant to the evaporator as per the cool ng load (i.e. refrigeration load) inside. Thus, the refrigeration or the air conditioning plant can be run to the optimum capacity as per the changing load requirements.

- TEV keeps the evaporator fully active and helps to obtain the optimum cooling effect.

- If the refrigerant entering the compressor contain liquid droplets, then It leads to breakdown of the compressor due to compression of liquid refrigerant. Since the entire refrigerant in the evaporator gets vapourized, therefore the chances of the liquid refrigerant particles going to the compressor are reduced. Thus, TEV increases life of compressor.

- The compressor can also work at the optimum capacity as per the refrigeration load on the system. If the load is lesser, it has to compress less amount of refrigerant and work on lesser capacity, thus consuming less electric power. If load is higher, it can also work at higher capacities.

Disadvantages of Thermostatic Expansion Valve

- Thermostatic expansion valve does not work well, if its feeler bulb is not in a good thermal contact with the refrigerant tube.

- If there is very small extent of superheating, thermostatic expansion valve cannot be used.