Resistance thermometer works on the principle of positive temperature coefficient. This principle states that “electric resistance of metals is directly proportional to temperature, i.e. electric resistance of metals increases with increase in temperature. Therefore, temperature of wire of any known material can be measured, if we measure its electrical resistance.

Resistance Thermometer Construction

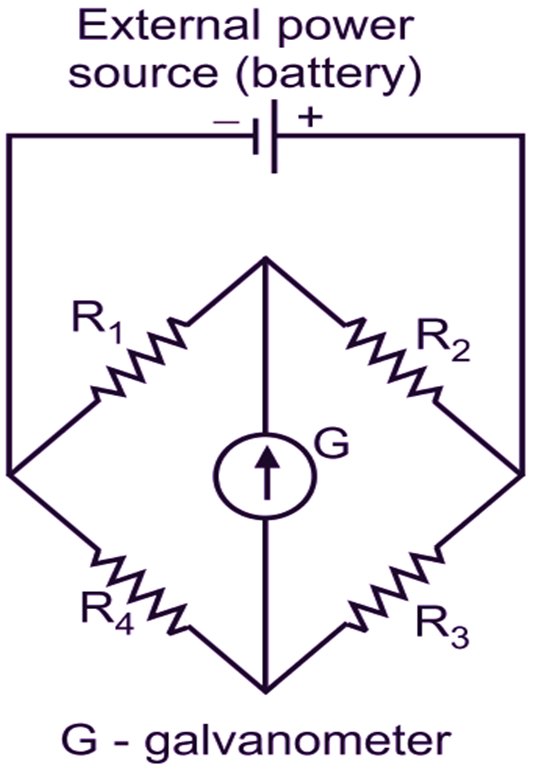

Sensing element is made up of meta having high positive temperature coefficient. Change in resistance caused by change in temperature is detected by the Wheatstone bridge. Materials are so selected that, values of Resistances R1, R2, R3 and R4, in four arms of bridge remain constant under a normal temperature. At this condition, galvanometer shows zero reading. Refer Fig. 1 (a). The galvanometer has a pointer placed in the plane of circular scale, which is directly calibrated in terms of temperature.

(a)

(b)

Fig. 1: Use of Wheatstone Bridge

When no current flows through the galvanometer, then according to normal principle of Wheatstone bridge,

\[\frac{{{\text{R}}_{\text{1}}}}{{{\text{R}}_{\text{3}}}}~=\frac{{{\text{R}}_{\text{4}}}}{{{\text{R}}_{\text{2}}}}\]

Now, fourth arm having resistance R4, is replaced by RTD’s sensing element, i.e. sensing Let Rt be the resistance of sensing wire. Due to change in temperature, resistance Rt changes and wheatstone bridge becomes unbalanced.

\[\frac{{{\text{R}}_{\text{1}}}}{{{\text{R}}_{\text{3}}}}~=\frac{{{\text{R}}_{\text{t}}}}{{{\text{R}}_{\text{2}}}}\]

This will make the pointer to move over the circular scale of galvanometer, which is calibrated in terms of temperature. position of pointer indicates the value of temperature measured. Refer Fig. 1 (b).

Resistance Thermometer Materials

- Essential Characteristics for RTD Material

- Change in resistance of material should be large enough for unit change in temperature.

- High resistivity, so that, minimum volume of material can be used for construction of RTD.

- Resistance of material should have a continuous and stable relationship with temperature.

Materials Used for Resistance Thermometer with operating Temperature Range (C)

Platinum: – 260°C to 110°C

Copper: 70°C to 120°C

Nickel: – 20°C to 200°C

Tungsten: – 200°C to 1000°C

Advantages of Resistance Thermometer

- Wide operating range from – 200°C to 1000°C.

- Easy to install and replace.

- Best suited for remote indication.

- Better sensitivity.

- Extremely accurate in sensing, measuring and displaying the temperature measured.

- Stability of performance over a long period of time.

- Linear Resistance-Temperature relationship.

Disadvantages of Resistance Thermometer

- High cost.

- Needs bridge circuit with power supply.

- Possibility of self-heating.

- Large bulb size required for measuring high temperatures.

- Sometimes, balancing of bridge takes more time.

Applications of Resistance Thermometer

- Temperature measurement in heat ng ovens, drying ovens, pressure vessels, baths etc.

- Temperature measurement of cold storage plant, boiler and power generator etc.

- For measurement of radiant heat.

- Food processing plants.

- Temperature measurement of exhaust gases.

- Petrochemical industries.

- Refrigeration and Air-conditioning applications.

- Process industries.

Note:

- If R0 = Resistance of RTD measured at temperature T0 (i.e. Temperature 0°C)

RT = Resistance of RTD measured at temperature T, when it comes in contact with hot surface or medium, and

αo = Temperature coefficient of material, then,

Resistance “RT” measured at temperature “T” in °C can be calculated by,

\[{{\text{R}}_{\text{T}}}~={{\text{R}}_{\text{0}}}\left[ 1+{{\alpha }_{\text{o}}}\left( \text{T}-{{\text{T}}_{\text{0}}} \right) \right]\]

- Unknown temperature “T” is calculated by,

\[\text{T}~=\left( \frac{{{\text{R}}_{\text{T}}}-{{\text{R}}_{\text{0}}}}{{{\text{R}}_{\text{100}}}-{{\text{R}}_{\text{0}}}} \right)\times 100\]

where,

R100 = Resistance of wire at temperature 100°C

R0 = Resistance of wire at temperature 0°C

Rt = Resistance of Wire at temperature T°C