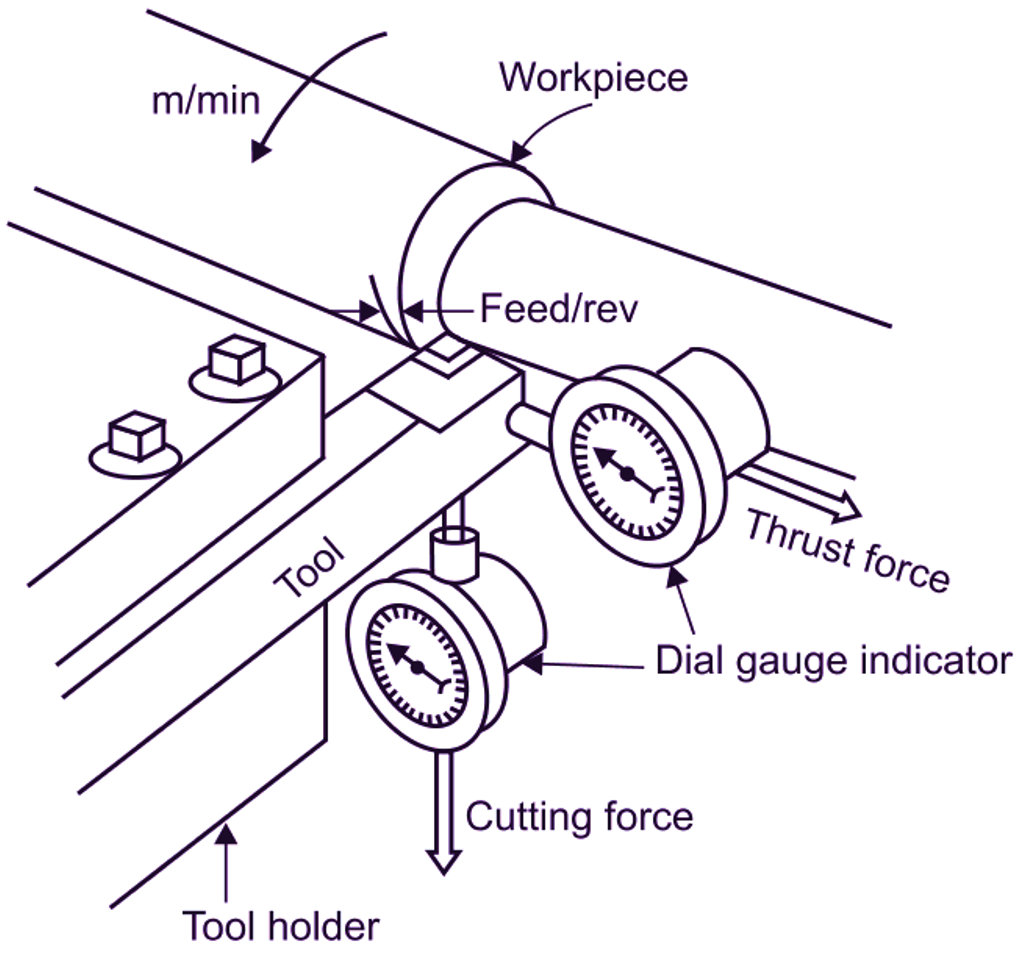

The lathe (or Mechanical) tool dynamometer measures deflection on the tool holder by the use of sensitive dial indicator.

Construction and Working of Lathe Tool Dynamometer

The lathe tool dynamometer consists of sensitive dial indicator for direct measurement of forces. Refer Fig. 1. The dial indicator is calibrated to read the cutting force. The deflection produced by it is directly proportional to the cutting force. The dial indcators are placed in direction of cutting force to find deflection. The cutting force or tangent a force will tend to deflect the tool and tool holder downwards, whereas, axial force or thrust force acting along the axis of the work piece will tend to push the tool away from the work piece. The deflection of dia indicator caused by the forces, cutting force and thrust force is calibrated in terms of the force.

Fig. 1: Lathe Tool Dynamometer

Advantages of Lathe Tool Dynamometer

- Simple method of tool force measurement.

- Economical method.

Disadvantages of Lathe Tool Dynamometer

- Chances of error.

- It cannot give digital readout.

Application of Lathe Tool Dynamometer

To find out various cutting forces acting in metal cutting on too (i.e. axial and tangential forces).