The submersible electric motors are the prime moves of an electric submersible pumping system. It is supplied with electrical power from surface via the cable and converts this into meaningful mechanical work. Submersible motors are generally squirrel cage type totally enclosed, wet type induction motor suitable for single phase, 230 V/3 phase, 415 volts, 50Hz supply, 2 pole 3000 RPM (Syn. speed) filled with pure drinking water. Dual seals and sand gaurds are provided for protection and to avoid contamination of outside bore well water.

There are different types of electric pumps submersible motor of 4”, 10” and 12”. Submersible motors are suitable to be immersed in well having diameter 4” and coupled to hydraulic submersible centrifugal pump with 4” coupling. The motors are designed to start at low voltage and worked in wide voltage fluctuation. It is available in rating of 0.37 kW to 2.2 kW.

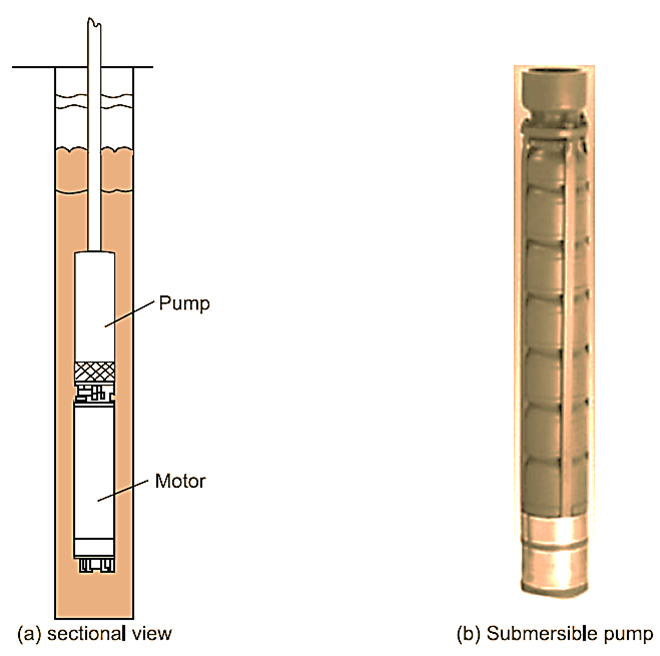

Fig. 1: The submersible pump with motor assembly

Salient Features of Submersible Motor

The following salient features of the electric motor used with submersible pump.

- Motors are squirrel cage type totally enclosed, wet type induction motor suitable for single phase, 230 V/3 phase, 415 volts, 50 Hz. A.C. supply, filled with pure drinking water.

- Dual seals are provided for protection and to avoid contamination of outside borewell water.

- The stator is made of stainless steel.

- It has low operating costs.

- It is made up of stainless steel jar.

- The lower suction housing is built on precision-cost steel;

- It is resistant to corrosion and it also ensures durability of motor.

- For the preventation of back flow of water, a stainless steel non-return valve is fitted.

- It offers protected diffusers and impellers

- Sand flush channels assist in the removal of particles that comes with pumped water.

Advantages of Submersible Motor

It has the following main advantages.

- Space: It requires very small space, does not required foundation or pump house.

- Investment Cost: Due to compact and sturdy design, the initial investment cost in less.

- Installation Cost: The installation cost is very low. It can be installed very in difficult site in narrow and slanting borewells.

- Maintenance Cost: Due to high accuracy, the maintenance cost in low.

- Noiseless Operation: The operation of pump is noiseless.

Application of Submersible Motor

The following are main applications of submersible motor:

- Multi-story buildings and complexes

- Irrigation and drip irrigation

- Industrial water supply schemes

- Nursery, Bungalows, Sprinkler and Gardening.