Check valve in its closed position provide an efficient sealing, i.e., avoid leakage completely. But a simple check valve is not suitable for all systems, as it allows flow only in one direction. The need for a better functioning of valve is fulfilled by the use of a pilot operated check valve.

Pilot operated check valve allows the forward as well as reverse flow with the help a external pilot pressure signal. Basic types of pilot operated check valves are,

- 4C valve

- 2C valve

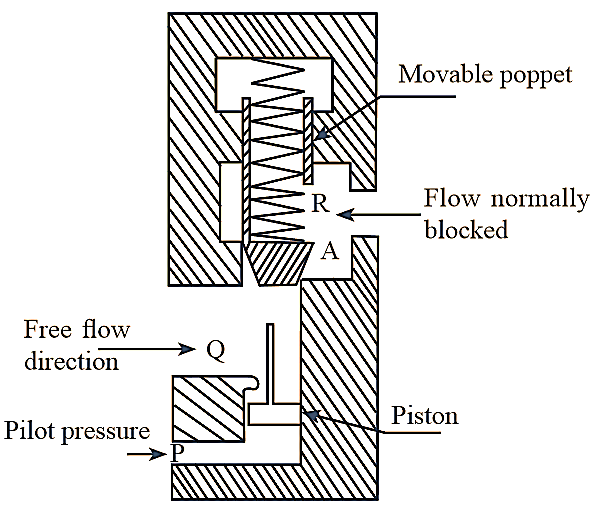

Figure (1): 4C Check Valve

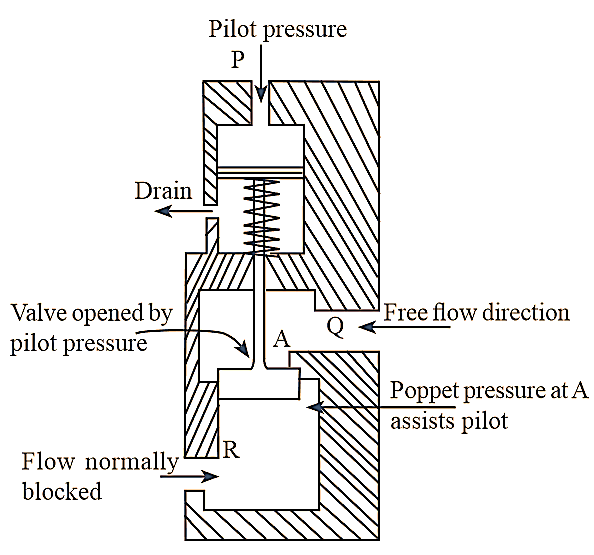

Figure (2): 2C Check Valve

The main difference between these valves and a basic check valve is that they use pilot pressure to open valves permanently. In a 4C check valve, the pressure of fluid at the inlet resists the pilot opening. But, in a 2C check valve, the pressure of fluid at the inlet acts in the direction same as that of pilot pressure.

The 4C check valve shown in figure (1) is in its closed position. In order to obtain flow through the valve, pilot pressure is applied at port ‘P’. Then, the piston moves tip against flow pressure at the inlet, and at the same time, the piston stem forces the poppet upward against spring force. Thus, orifice ‘A’ gets opened and liquid from port ‘Q’ leaves through port ‘R’.

In 2C type check valve, pilot pressure at the port ‘P’ and initial flow pressure at the port ‘Q’ combinedly cause poppet to move downwards. Thus, orifice ‘A’ is opened and reversed flow through port ‘R’ is obtained. In the figure (2), the cylinder with pilot check valves is shown. Cylinder has the pressure line feeding system to which the pilot lines are connected.

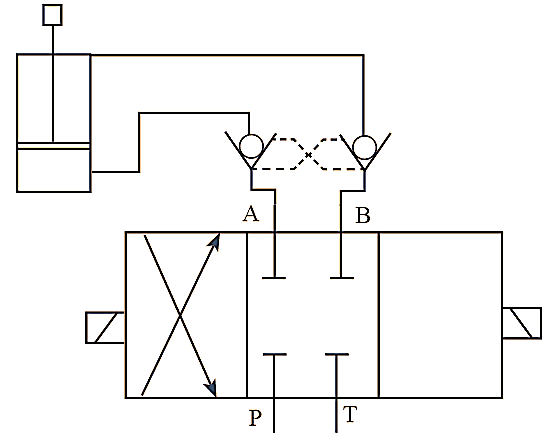

To obtain reciprocation of cylinder, one of the check valves is kept open by the pressure of pilot signal while the other valve acting as normal check valve is gets opened by fluid flow. When these valves are closed, the cylinder will stop reciprocating and thus, it is locked hydraulically (Figure 3).

Figure 3: Cylinder with Pilot Check Valve