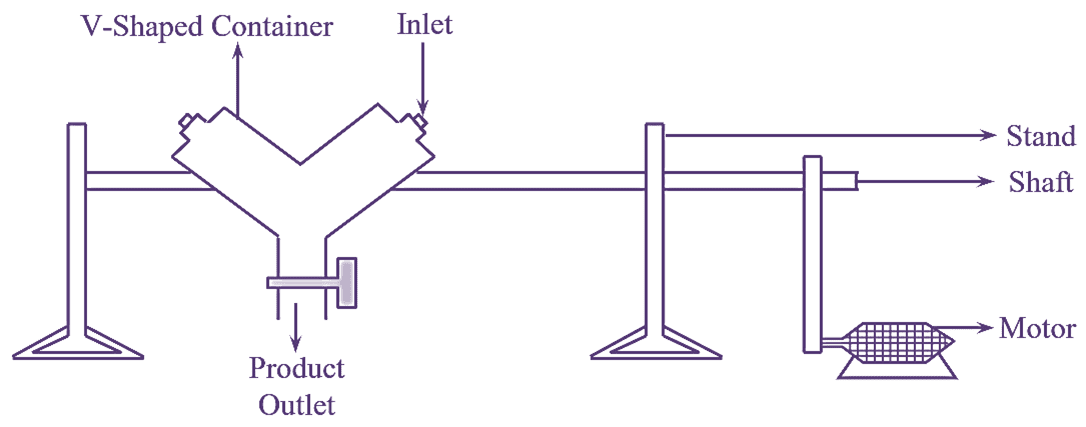

Figure 1: Twin Shell Blender.

Working Principle of Twin Shell Blender

The principle involved in twin shell blender is tumbling and cascade action.

Construction of Twin Shell Blender

It is a tumbling mixer with no mixing blade. It consists of V-shaped container provided with two inlets on either side or an outlet at the bottom. It is held by a horizontal shaft, the ends of which are fitted to the stands on either side. One end of the shaft is extended and is connected to a motor. The equipment is made up of stainless steel or plastic.

Working of Twin Shell Blender

Material is introduced into the container through the inlets provided and is filled up to 50-60

Advantages of Twin Shell Blender

- Most suitable for blending solids containing fragile granules because of low attrition.

- Useful for large scale mixing.

- Easy to load and unload.

- Ease of cleaning.

- Low maintenance cost.

Disadvantages of Twin Shell Blender

- Requires more space.

- Not applicable for powders with varying particle size and also for fine particles.

- Free flowing powders require serial dilution for mixing highly potent drugs.

Applications of Twin Shell Blender

- Useful for mixing dry solids.

Double Cone Blender

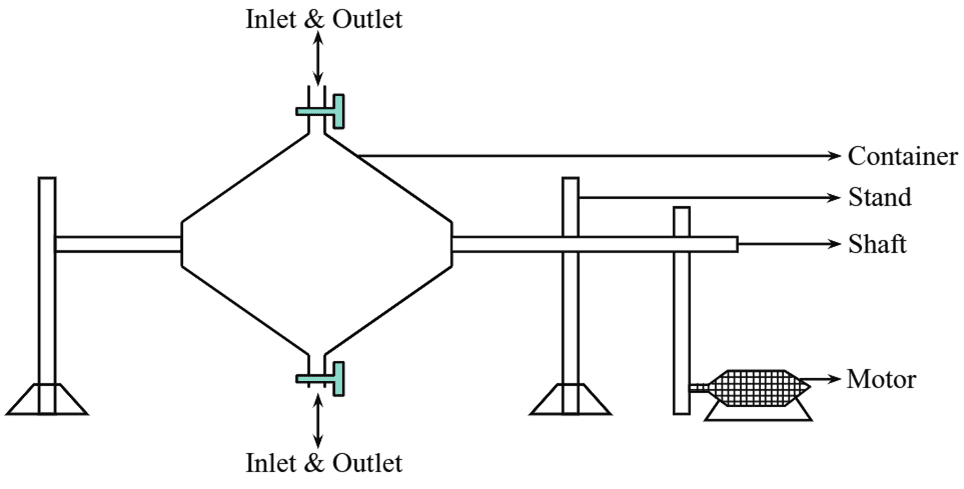

Figure 1: Double Cone Blender.

The principle and operation of double cone blender is similar to that of twin shell/V-cone blender, but differs only in the shape of the container.

It is also a tumbling mixer with no mixing blade. It consists of a double cone shaped container provided with openings on both ends, through which the material can be loaded and unloaded. It is made up of stainless steel. It is connected to a motor by means of a shaft that facilitates the rotation of the container. The entire assembly is held on a stand made up of iron.

It facilitates efficient mixing of powders containing particles of varying densities and also when the amount of powder is less because of good rolling action provided by the shape. The merits, demerits and application of double cone blender are similar to that of twin shell/V-cone blender.