Working Principle of End Runner Mill

End Runner Mill works on the principle of compression and shearing stress offered to the feed by the heavy weight steel pestle. However, its use has become obsolete.

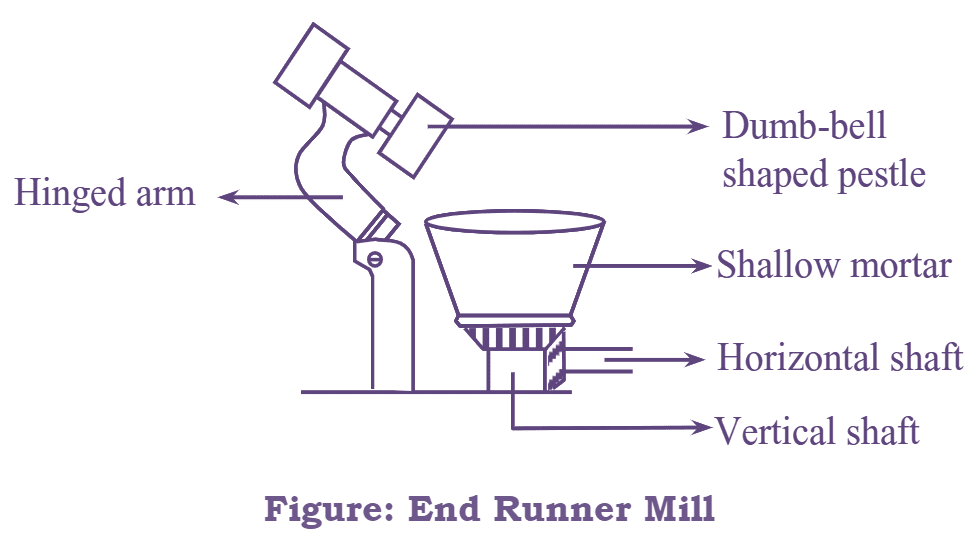

Construction of End Runner Mill

It is basically a mechanical mortar and pestle. The shallow mortar is made up of bed of stones or mild steel. The pestle has a flat bottom and is cylindrical and dumb bell shaped. The pestle is arranged eccentrically on the shallow mortar. The pestle carries a hinged arm so that it facilitates in emptying the feed and for cleaning the device just by raising the pestle. Inside the shallow mortar, a scrapper is arranged which brings the feed material towards the grinding surface.

Working of End Runner Mill

Feed material is introduced in the mortar and the motor is switched on. The mortar revolves, which leads to the rotation of the pestle. This rotation is due to the friction produced between the contacting surfaces of the mortar and the pestle. The scrapper brings the material towards the grinding zone. The material is size reduced by crushing and shearing phenomena. The product is collected and then sieved to obtain the desired particle size.

Advantages of End Runner Mill

- It is a laboratory scale mill.

Disadvantages of End Runner Mill

- Unbroken drugs or those in slightly broken conditions cannot be milled by end runner mill.

Applications of End Runner Mill

- Brittle and crystalline feed materials are size reduced to fine powder.