A dead weight tester is commonly used as a source of standard pressure for calibration purposes. It is basically a pressure producing and pressure measuring device.

Construction & Working Dead Weight Tester

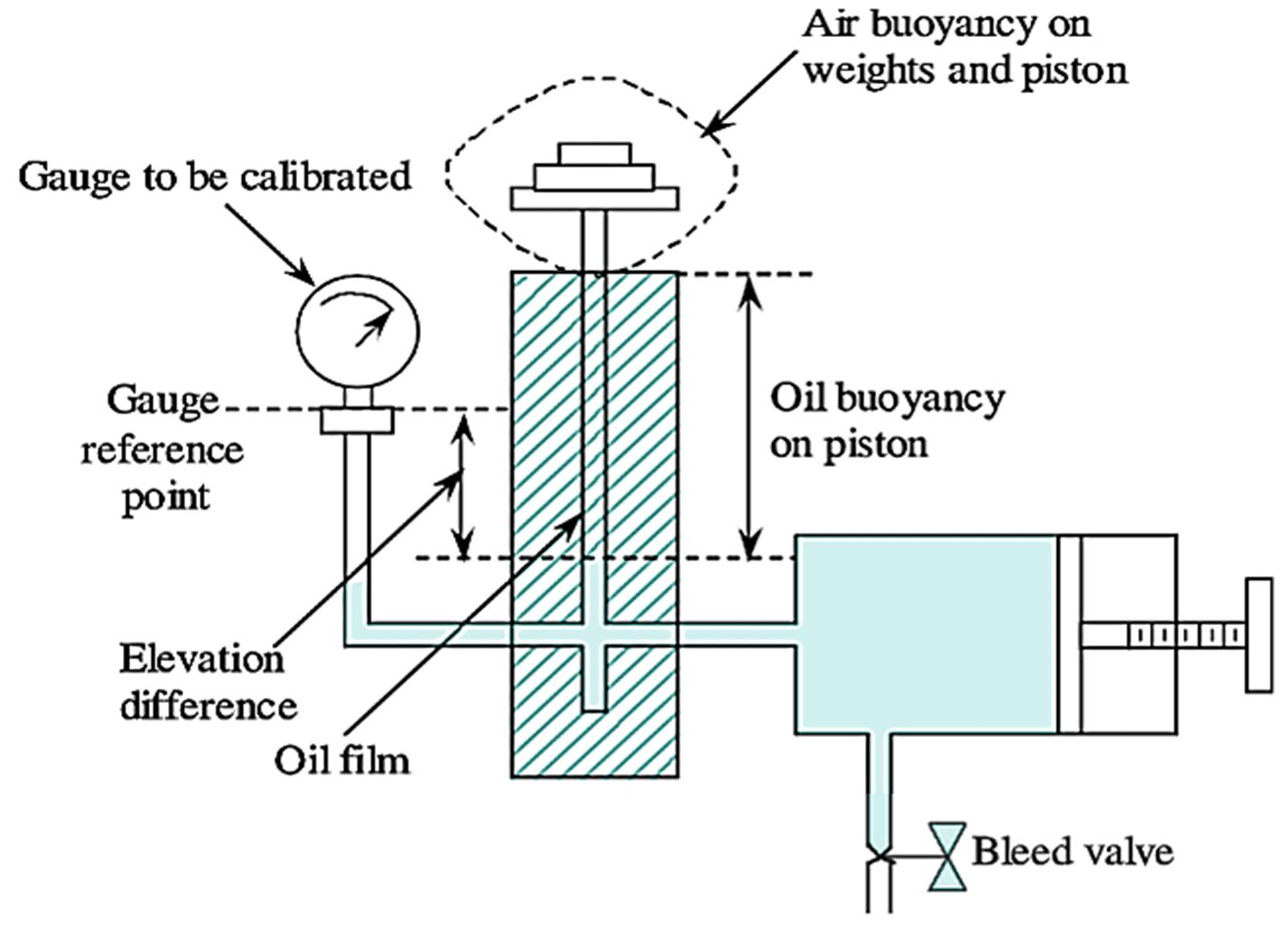

A typical dead weight or piston gauge is schematically shown in the following figure 1,

Figure 1: Dead Weight Tester.

It consists of a chamber in which fluid is filled. The calibrated gauge is connected to the chamber. A pump and bleed valve are attached to the chamber so as to adjust the pressure of the fluid present in the chamber. A vertical piston cylinder is also connected to the chamber and different standard weights are applied to this cylinder. The third pressure is applied to the other side of the piston by operating the plunger. This pressure is applied until the piston and weights are seen to float. At this point the third gauge pressure is given by.

\[P=\frac{W}{a}\]

Where,

P = Fluid gauge pressure

W = Dead weight supported by the piston

a = Area of the piston.

Thus the pressure caused due to the weight placed on the vertical piston is calculated by using the above equation. To achieve high accurate results, frictional force between the cylinder and piston must be reduced which is generally accomplished by rotating the piston while the reading is taken.

Calibration of Pressure Measuring Instrument Using Dead Weight Tester

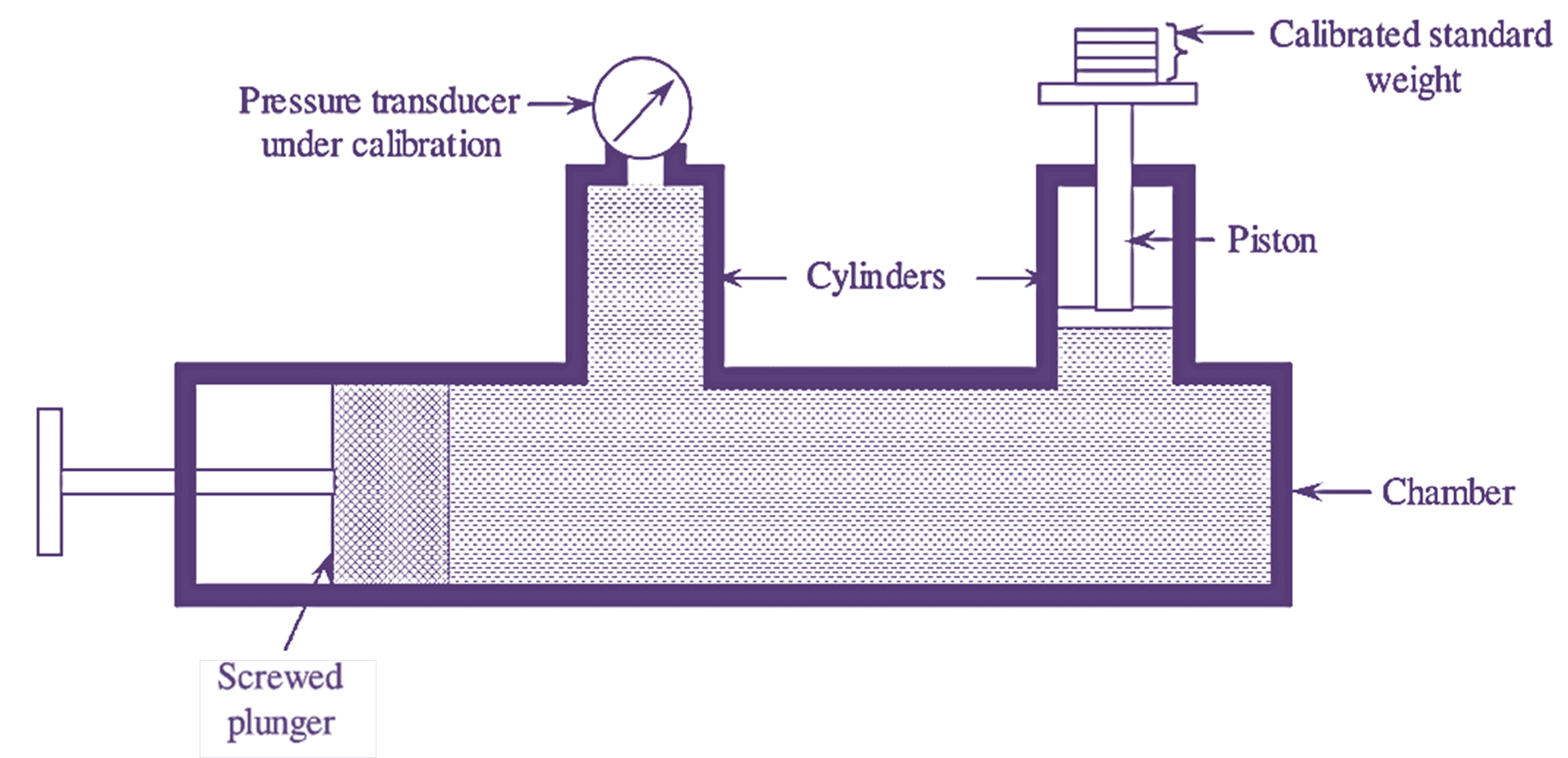

Figure 2: Dead Weight Tester for Pressure Calibration.

Static calibration of pressure transducers is carried by dead weight tester. It is the basic standard pressure calibration device. The dead weight tester can be operated by hydraulic means or pneumatic means. The schematic of dead weight tester is shown in the figure 2.

The dead weight tester consists of a chamber filled with fluid. Two accurately machined cylinders of known cross-section area are attached to the chamber. An accurately machined cylinder is closely fitted into one of the cylinders. This piston has a platform on its top so that the piston can be loaded with weights. A screwed plunger is incorporated into the chamber from one of its sides as shown in figure 2.

Dead Weight Tester Calibration Procedure

The pressure transducer to be calibrated is connected to the other cylinder of dead weight tester and the piston is loaded with standard weights of high accuracy. Then, due to the gravitational force acting on these standard weights, a force is exerted on the known area i.e., an equivalent force of piston-weight combination acts on the fluid and develops a pressure on the fluid in the chamber.

Now, pressure is applied on the fluid from the other end by operating the plunger inwards until the combination of piston and standard weights float freely. At this condition the force of the piston-weight combination is equal to the force of the fluid pressure.

i.e.,

\[F\text{ }=\text{ }PA\]

Where,

F = Equivalent force of the piston-weight combination

= Mg (M = Total mass, g = Acceleration due to gravity)

P = Fluid pressure

A = Equivalent area of piston-cylinder combination

\[P=\frac{F}{A}\]

\[P=\frac{Mg}{A}…(1)\]

At equilibrium condition, the pressure developed on the fluid in the chamber is transmitted to the pressure gauge under calibration. The reading then indicated by the pressure gauge is equal to the value of P calculated from equation (1) above.

- The static calibration of low pressure transducers is carried out by standard mercury or water manometers because these manometers provide accurate measurements of low pressure.

- Pressure transducers can also be calibrated using secondary standards of pressure such as helical type bourdon gauges made up of quartz and force balance type pressure transducer.

Advantages of Dead Weight Tester

- Its construction is simple and is very easy to operate.

- It is used as a standard for calibration of a wide range of pressure measuring devices.

- Fluid pressure can be varied easily either by adding pistons or by changing the piston cylinder.

Disadvantages of Dead Weight Tester

- Friction between the piston and cylinder affects the accuracy of the gauge.

- The gravitational force also affects the accuracy of the gauge.

Applications of Dead Weight Tester

It is used to measure pressure and also to calibrate all kinds of pressure gauges.

Factors Affecting the Accuracy of Dead Weight Tester

The following are the factors affecting the accuracy of dead weight tester,

- The presence of friction between the piston and the cylinder.

- Uncertainties in the value of gravitational constant.

- Ambiguous value of effective area of piston cylinder.

- Gravity

- Mass, height and air buoyancy

- Head of transmitting fluid

- Elastic deformation of piston and cylinder

- Thermal expansion

- Weight of the fluid buoyancy

- Levelness and cleanliness