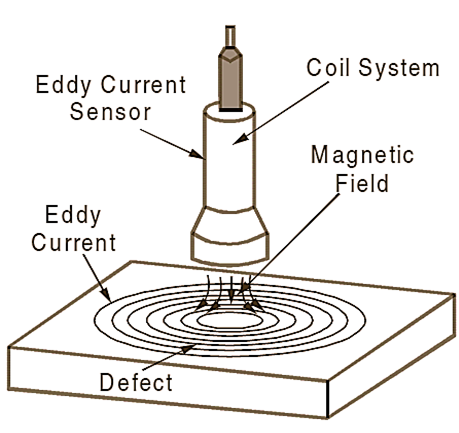

Eddy current is circular current which is induced by a conductor when it is kept in a changing magnetic field. Eddy current sensors are used as proximity sensors to detect the presence or absence of non-magnetic conductive material. It is a non-contact sensor (see Figure 1).

Figure 1: Eddy Current Sensor.

Construction of Eddy Current Sensor

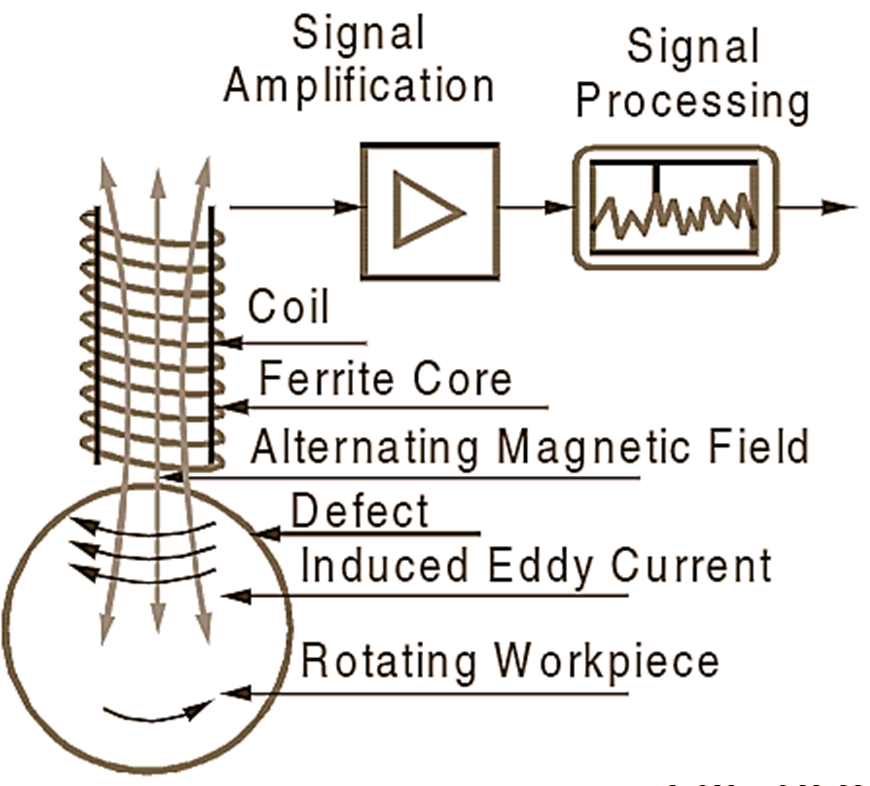

Figure 1: Eddy Current Sensor Construction.

The eddy current sensor consists of a coil wound on a ferrite core connected to a signal amplifier and a signal processor as shown in Fig. 2. The coil has an AC supply. The coil and the core arrangement are made inside a probe. This probe is connected to the signal processing unit with the signal amplifier and signal analyzer. As per the application, the signal processing unit can be calibrated to indicate the parameter which is to be measured.

Working Principle of Eddy Current Sensor

When supply is given to the sensing coil, it produces a magnetic field. When this magnetic field cuts the work piece, it generates Eddy current in it. The Eddy current in the work piece generates a magnetic field opposite to the sensing coil’s magnetic field. Eddy current is very weak. Hence the magnetic field it produces is also very weak. When two magnetic field clashes, it produces a small distortion which is detected by the signal processing unit. These small distortion signals are recognized when it is amplified and analysed. Based on the applications, this sensor is used with the signal processing unit programmed.

This sensor is very accurate and cost of construction is low. It can be used in extreme conditions as it is not temperature sensitive. Only problem is the distance from the target must be less.

Applications of Eddy Current Sensor

- Automation requires precise location.

- Monitoring of Machine tool.

- Final assembly of precision equipment such as disk drives

- Monitoring of Driveshaft.

- Measurements of Vibration.

- Precision stage positioning.