Range: Up to 12000 r.p.m.

Accuracy: ±3 % of full scale.

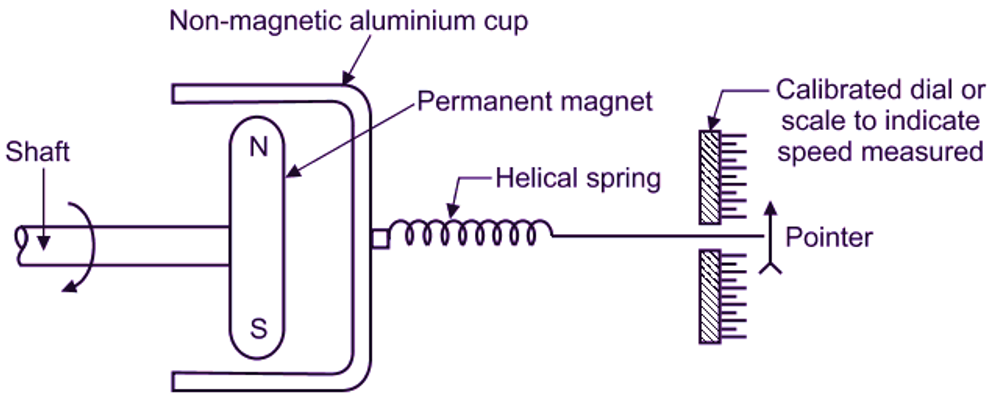

Construction of Eddy Current Tachometer

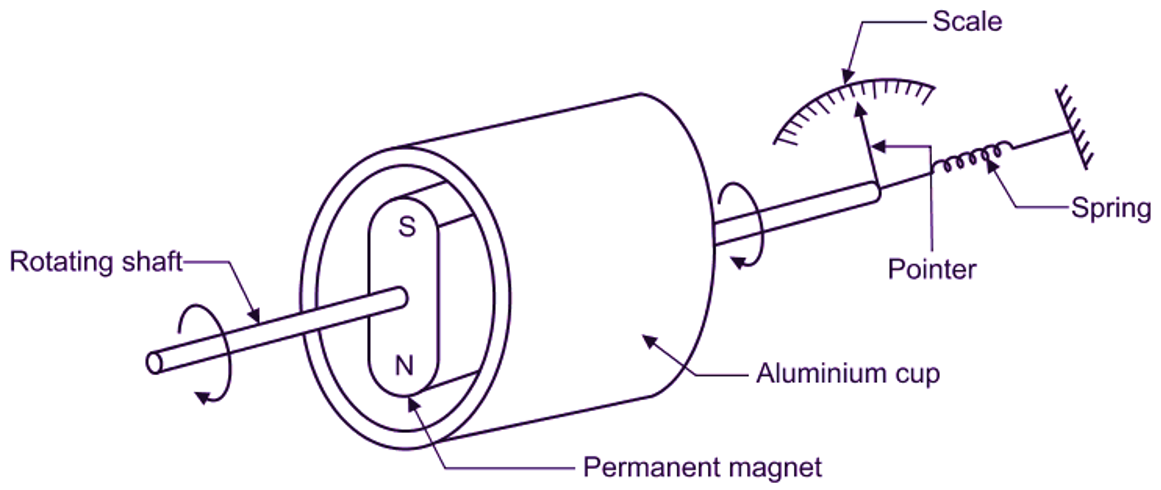

It is a contact type of electrical tachometer, i.e. physical contact is made with the shaft, whose speed is to be measured. In this type of tachometer, the transducer produces an analog signal in the form of continuous drag due to eddy current, induced in the cup. The current, which is indicated by an analog indicator on a scale, is proportional to the speed. The machine shaft, whose speed is to be measured, is engaged with the tachometer shaft. This tachometer shaft is connected to a permanent magnet. The magnet is surrounded by a cup made up of nonmagnetic, but conductive material, such as aluminum. The other end of non-magnetic aluminum cup is connected to the pointer through a helical spring.

Fig. 1: Eddy Current Tachometer

Working of Eddy Current Tachometer

Due to rotation of machine shaft, the connected tachometer shaft and hence, the magnet starts rotating. This rotation of magnet induces eddy currents and hence, emf in the non-magnetic aluminum cup. The induced eddy currents produce a twisting moment or torque in the cup, which acts against the torque of helical spring. Due to the induced torque, the cup turns in the direction of rotating magnet, till the torque induced (developed) becomes equal to torque on helical spring. The pointer attached to the cup moves over a calibrated scale (dial), indicating the angular speed of shaft.

Fig. 4.10: Illustrative View of Eddy Current Tachometer

Note: Eddy current is a type of current generated in a conductor (non-magnetic aluminum cup), which lies in the vicinity of magnetic field.

Advantages of Eddy Current Tachometer

- Low cost.

- Rigid in construction.

- Very low maintenance.

Disadvantages of Eddy Current Tachometer

- At a very high speed, it gives non-linear characteristics for output voltage and speed of shaft.

- To calibrate this type of tachometer, it is essential that, input voltage must be maintained absolutely constant.

Applications of Eddy Current Tachometer

- Automobile speedometer.

- Aircraft engines.

- Industrial applications.

- For measuring speed of locomotives.