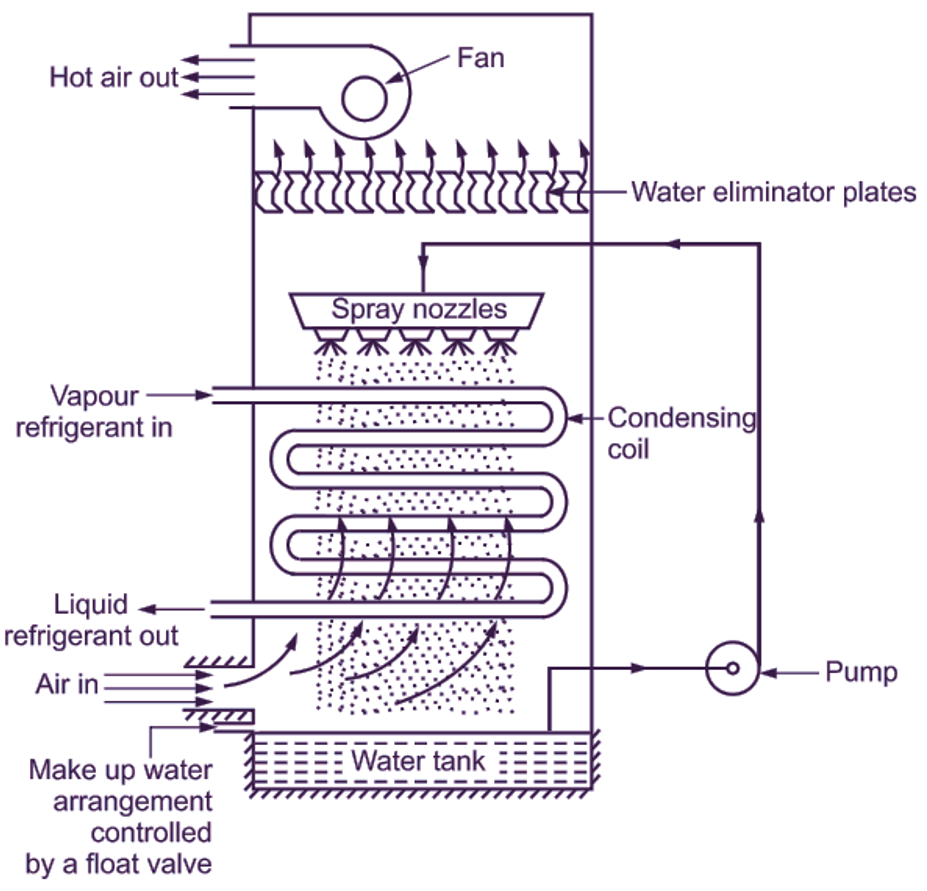

The evaporative condensers use both air and water as condensing mediums to condense the hot vapour refrigerant and convert it into liquid refrigerant. In short, it is a type of indirect cooling, where heat of vapour refrigerant is taken by water and water is cooled by air. These condensers perform the combined functions of a water cooled condenser and a cooling tower. Water is pumped from a water tank to a spray header (with nozzles) and it is sprayed through nozzles over the condenser coils, through which, the hot vapour refrigerant received from the compressor is flowing. Heat is transferred from the vapour refrigerant through the condensing tube walls to the outside water, which is passing over the outside surface of tubes. Due to heat rejected by hot vapour refrigerant to the cold water, it becomes liquid refrigerant. At the same time, air is drawn from the bottom side of the condenser by a fan (located at top). The air is discharged out from the top of the condenser. The air causes the water droplets adhered to the surface of the condenser coils to evaporate by absorbing the heat from the remaining water, which is required for their evaporation. The heat absorbed by these water droplets is called as latent heat of evaporation or vapourization. Due to heat rejection, remaining water gets cooled. This cod water collected in the water tank at bottom is again re-circulated into the circuit. At the same time, air also absorbs some part of heat from water droplets to evaporate them. Thus, the air becomes hot and is discharged from top to the atmosphpere. In order to make up the deficiency of water caused by the evaporated water, make-up water is supplied to the water tank. A float valve in the water tank controls the make-up supply. Water eliminator plates are provided above the spray header to prevent particles of water along with the escaping discharged air.

Fig. 1: Evaporative condenser

Advantages of Evaporative condenser

- Used in large capacity systems.

- Cheaper as compared to water cooled condensers, which require a separate cooling tower.

- Since water is used in a closed loop, only a small part of water evaporates.

- Preferred in places, where water is not available in much quantity.

- Make-up water is supplied to take care of the evaporative loss.

- The water consumption is typically very low, about 5

Disadvantages of Evaporative Condensers

- As the condenser has to be kept outside, this type of condenser requires a longer length of refrigerant tubing.

- Large amount of refrigerant is required due to longer tubing.

Types of Evaporative Condensers

- Pad type evaporative condenser.

- Spray type evaporative condenser.

- Rotating type evaporative condenser.

Following are the factors affecting selection of condenser.

- Capacity of the refrigeration system.

- Purity of refrigerant.

- The type of refrigerant used.

- The type of cooling medium available.

- The quantity of cooling medium available.

- Velocity of cooling medium.