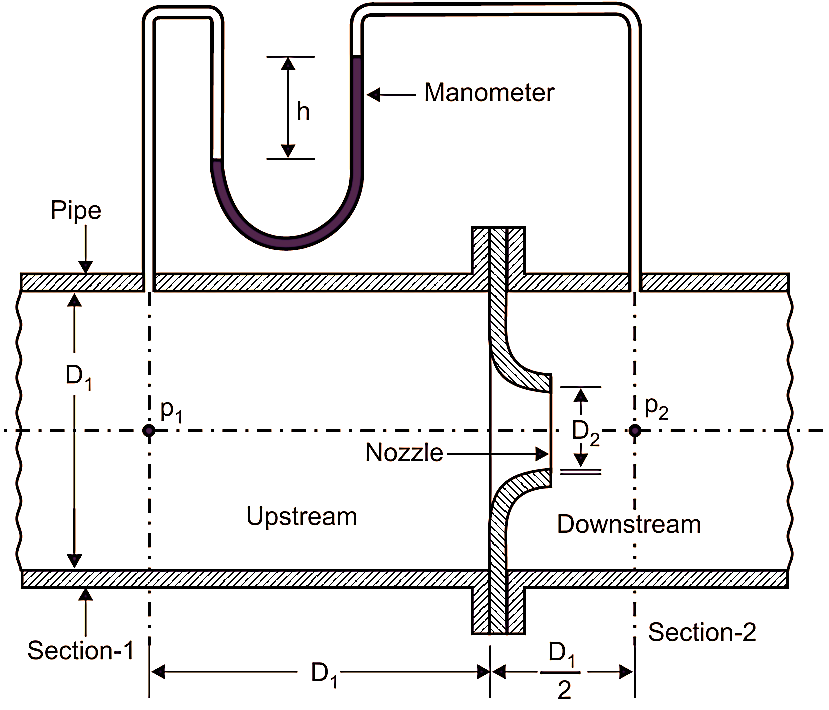

A flow nozzle operates on the principle of variable head type flow meter. Differential pressure is developed by inserting flow nozzle in the pipe as shown in Fig. 1. A flow nozzle consists of a convergent inlet, whose shape is quarter ellipse with cylindrical throat. Differential pressure measurement taps are provided on pipe diameter upstream and one-half diameter downstream from the inlet faces of nozzle. Stainless steel is the most commonly used material for manufacturing of flow nozzle. Discharge or the flow rate depends upon the pressure difference measured by U-tube differential manometer. Discharge can be calculated by using the formulae used in case of venturimeter and orifice meter discussed in previous sub-articles.

Fig. 1: Flow Nozzle

Advantages of Flow Nozzle

- They have higher coefficient Of discharge than that of orifice meter.

- Cheaper and easier to install.

- Physical length is less as compared to venturimeter.

- Quite useful for measurement of flow of fluids containing settled solids.

- Widely used for high pressure/temperature steam flow.

- Being more rugged and more resistant to erosion than sharp edged orifice, they can be used for flow measurements at high velocities.

Disadvantages of Flow Nozzle

- Owing to poor pressure recovery, they are not useful for applications, where pressure heads are small or where pressure recovery is a must.

- It is expensive and difficult to install as compared to orifice meter.

- Limited moderate pipe sizes, not available above 120 cm.

- Higher maintenance.