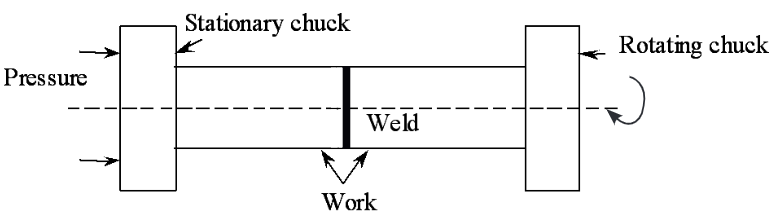

Figure 1: Friction Welding.

In friction welding, the heat is obtained by the friction between the surfaces of the two parts which are to be joined. These parts are held under pressure, where one part is stationary and other part is made to rotate at high speed. The welded joint is obtained hen a force on the stationary part is applied, after stopping the rotation of the part (see Figure 1).

High friction created due to rotation of the part is converted into heat, this heats the surfaces to high temperature below its melting point. The speed of rotation ranges from 1500 -3000 r.p.m. The weld is completed, when the relative motion between the two parts is stopped with the application of high pressure.

Friction welding is done for 2 to 30 seconds. This type of welding is used for circular parts like bars and pipes etc. The heat effected zone is very narrow and due to which the dissimilar metals can be easily joined.

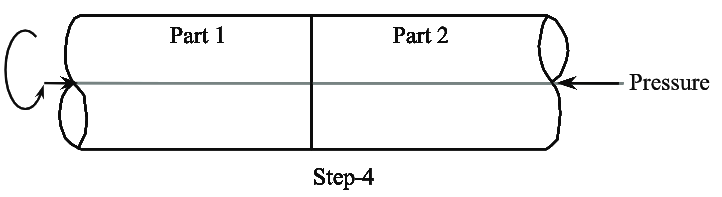

Steps involved in Friction Welding

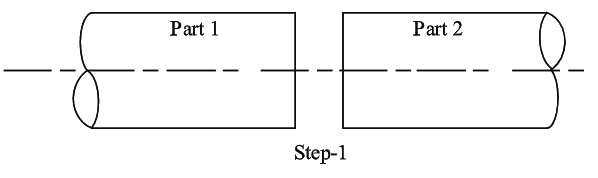

Step-1

The two parts to be welded should be held in axial alignment.

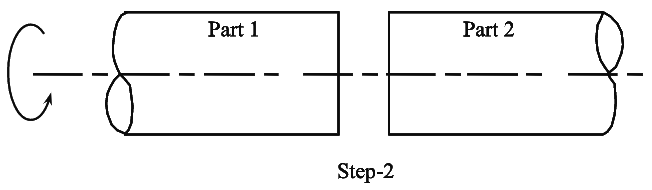

Step-2

One of the parts is rotated and accelerated to the required speed, by holding it in the chuck or spindle of a machine.

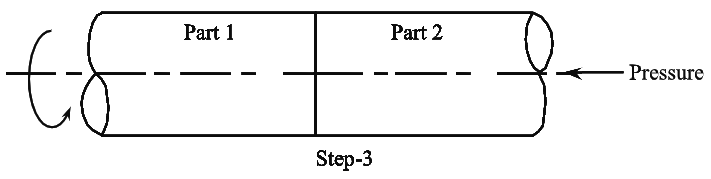

Step-3

The part held stationary in a movable clamp is now moved towards the rotating component, such that a pressure contact is maintained between them.

Step-4

Pressure is maintained continuously till the high temperature at the contact surface makes the metals plastic for welding. The metal is extruded from the weld region to form an upset.

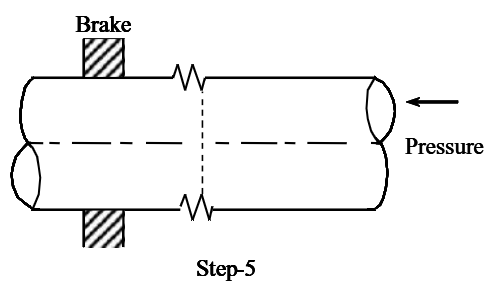

Step-5

After sufficient heating at the interface, the rotation is stopped by applying the brakes and axial force is further increased to forge the two components.

Advantages of Friction Welding

- High quality of weld can be obtained.

- Annealing of weld zone is not required.

- Power required is less.

- Process is simple and requires less skilled person.

- Initial cost is less.

- It is a clean process.

- Dissimilar metals can be easily joined.