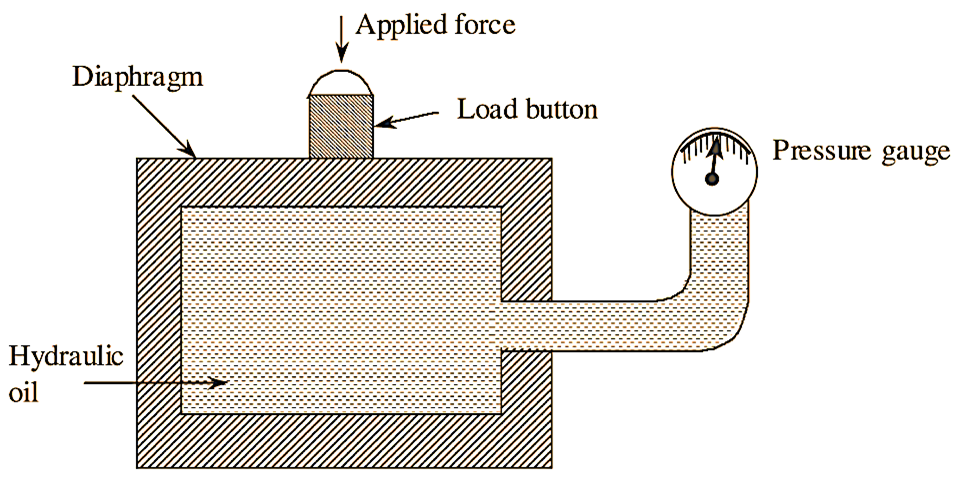

Figure 1: Hydraulic Load Cell.

The principle of operation of hydraulic load cell is when a force is applied on a liquid medium, the pressure of the liquid increases. This increase in pressure is a measure of the applied force when calibrated. The figure 1 shows the basic schematic representation of hydraulic load cell. It is also known as a hydraulic plunger.

Hydraulic oil is filled in a closed chamber whose height is 0.75 mm. The force to be measured is applied ou the diaphragm. The applied force moves the diaphragm downwards and thus closes the chamber from the top. The pressure of the liquid increases due to the applied force. This increase in pressure of the liquid is measured by employing mechanical or electrical pressure gauge. When full load is applied the maximum of 0.05 mm deflection occurs. This type of load cell can measure force upto 500 tonnes. This type of load cells gives good accuracy and resolution when the force is about 20 tonnes. For gauge checking hydraulic load cell uses 200 kPa pressure as the preload.

Advantages of Hydraulic Load Cell

- Hydraulic load cells exhibit quick response to load changes.

- Their performance is independent of variations in temperature.

- As they do not use any excitation source, they can be used in hazardous areas.

- They can withstand high overloads.

- They can measure high impact loads with great accuracy.

- They do not cause any trouble when used over extended.

- As they do not use any excitation source, they can be used in hazardous areas.

Disadvantages of Hydraulic Load Cell

- They are bulky and occupies much space.

- Cost of oil is high.

- Transportation is difficult.

- Maintenance is difficult.