IC Engine (Internal combustion engine) is a type of heat engine which converts the heat energy released during combustion of fuel into mechanical work. As the combustion takes place within the engine cylinder it is named as internal combustion engine. This type of engine makes use of liquid and gaseous fuels for combustion. Most of the modern IC engines works on operating cycles such as Otto and Diesel cycles. They are used in automobiles, industries and in many other applications. Different types of IC engines are two stroke engine, four stroke engine, petrol engine, etc.

Parts of IC engine

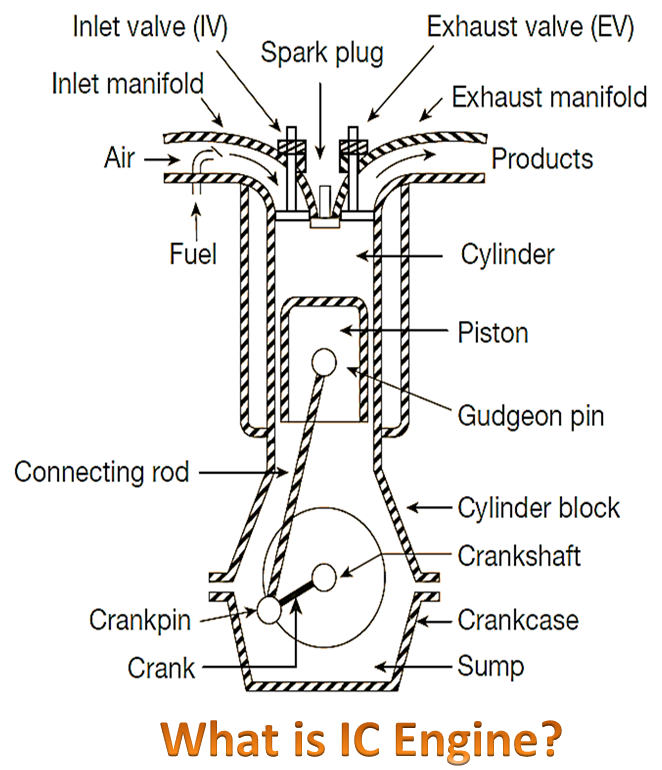

The schematic diagram of an IC engine is shown in figure 1. The various parts and the terms associated with IC engine are labelled in figure 1.

Figure 1: Parts of IC engine.

The description of the main components of IC engines is discussed below.

Cylinder: It is considered as the heart of an engine in which the combustion of fuel takes place. The inside diameter of the cylinder is called as bore. In order to protect the cylinder from wear, liners or sleeves are sometimes inserted into the cylinder. The material for the cylinder should be such that, it should withstand high pressure and temperature of the combustion of fuel.

Piston: It is a close fitted cylindrical plunger, which moves to and fro inside an engine cylinder. The main function of piston is to transmit the force exerted due to combustion of fuel to the connecting rod which in turn transmit it to the crankshaft to produce mechanical power.

Piston Rings: The piston rings are the metallic rings inserted into the circumferential grooves provided at the top end of the piston. These rings maintain a gas tight joint between the piston and the cylinder while the piston is reciprocating in the cylinder. They also helps in conducting the heat from the piston to the cylinder walls.

Connecting Rod: It is the link that connects the piston and the crankshaft by means ofpinj oints. It converts the reciprocating movement of piston into circular motion (or rotary motion) of crankshaft as it is subjected to alternatively tensile and compressive stresses as well as bending stresses. Therefore, it should be desiìed and manufactured carefully.

Crank and Crankshaft: A crank is a lever that is connected to the end of the connecting rod by a pin joint with its other end connected rigidly to a shaft called crankshaft. It rotates about the axis of the crankshaft and causes the connecting rod to oscillate. The main function of crankshaft is to convert the reciprocating motion of the piston into rotary motion with the help of connecting rod.

Valves: The valves are the devices, which controls the flow of the intake charge and the exhaust gases that are released from the engine cylinder respectively. They are also called poppet valves. These valves are operated by means of cams driven by the crankshaft through a timing gear or chain.

Flywheel: It is a heavy wheel mounted on the crankshaft of the engine to maintain uniform rotation of the crankshaft.

Crank Case: It is the lower part of an engine. serving as an enclosure for the crankshaft arid also as a reservoir for lubricating oil.

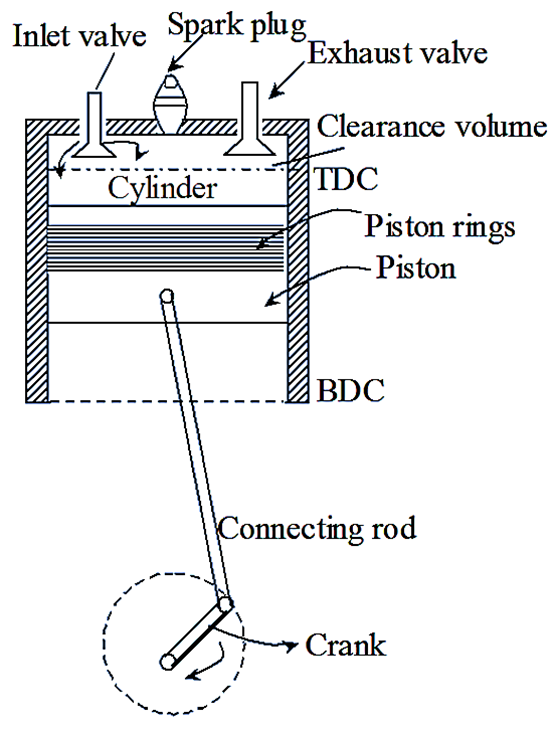

TDC (Top Dead Centre): It is defined as the position of the piston when it is at its top most position or when the volume in the cylinder is lowest.

BDC (Bottom Dead Centre): It is the position of the piston when the volume in the cylinder is maximum or when the piston is at its lowest position.

Swept Volume: It is the volume swept by the piston when moving from TDC to BDC or TDC to BDC.

Clearance Volume: It is the volume remains in the cylinder when the piston is in TDC position.

Materials used for the components of IC engine

| Components Parts | Materials Used |

| Cylinder | Hard grade cast iron |

| Crank case | Cast iron or cast aluminium |

| Crank pin | Special steel alloys |

| Crank | Forged steels |

| Crank shaft | Steels or nickel alloy castings |

| Connecting rod | Nickel, Chrome and chrome vanadium steels |

| Wrist pin | Hardened steel |

| Piston | Aluminium alloys (or) Alloy steels |

| Cylinder head | Cast iron or aluminium |

| Exhaust valve | Chrome alloys |

| Inlet valve | Chromium-nickel alloys |

Requirements of an IC engine

The requirements of an IC engine are as follows,

- The engine should develop high HP.

- The weight per unit power required should be low

- It should have high thermal and mechanical efficiency.

- It should be simple and compact in size.

- Initial cost should be low.

- Fuel required per unit HP should be less.

- It should provide effective combustion of fuel inside the cylinder.

- Maximum mean effective pressure (MEP) should be developed.

Types of IC engine

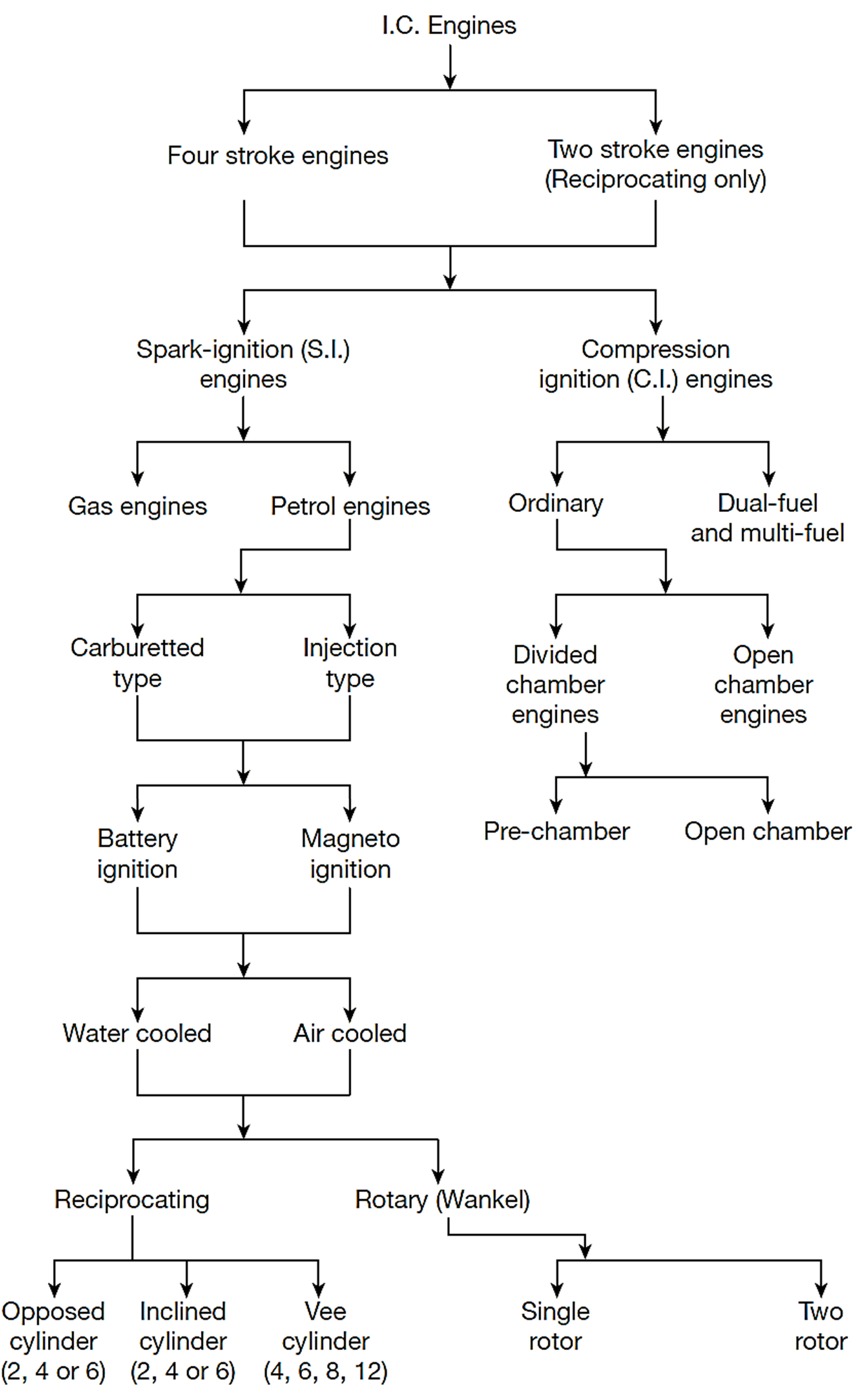

Figure 2 shows the classification of IC engines are based upon the following parameters,

- Type of cycle

- Type of fuel

- Cycle of combustion

- Method of ignition

- Number of cylinders

- Method of cooling

- Arrangement of cylinder

- Speed of engine

- Method of governing etc.

Figure 2: IC engine classification.

Advantages of IC Engines Over External Combustion Engines

- IC engines have high overall efficiency.

- Low weight power ratio.

- Initial cost is low

- Even in cold conditions, they can be started easily.

- Requires less space due to their compact sizes.

- Mechanical simplicity is more.

Applications of IC Engine

- Vehicles such as scooters, buses etc.

- Air crafts.

- Construction equipments such as bull-dozers, power shovels etc.

- Industries.

- Locomotives.

- Pumping sets.

What are the functions of governor in an internal combustion engine?

The functions of a governor are,

- To control the speed of an engine under varying load conditions.

- It maintains the amount of working fluid to be supplied.

- It regulates the mean speed of engine cycle within specified limits at any instant of time.

- It fulfills the varying demand for power.

- It is a key element of an engine and mostly employed in automobile engines.