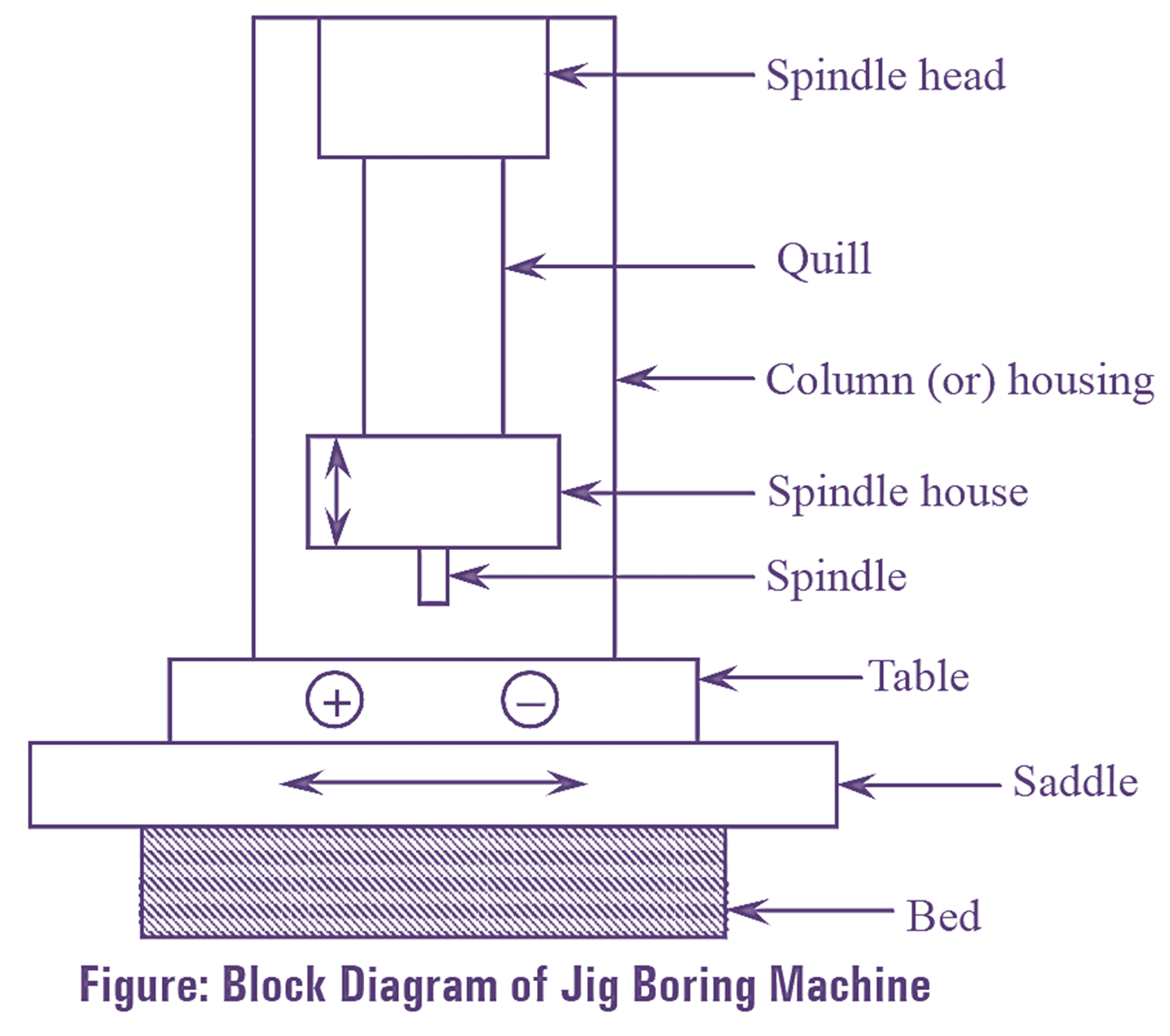

Among all the machine tools, the jig boring machine is most accurate (accuracy ranges from 0.0025 mm) and precise. These machines are mainly used to manufacture components which need a greater degree of accuracy like jigs. fixtures, tools, etc. A typical diagram of jig boring machine is shown in the figure.

Parts of Jig Boring Machine

Bed:

It is a box type and rigid construction. It acts as main supporting member. It supports a vertical colunm at the back and saddle at the front.

Table and Saddle:

The saddle is mounted on the base. It gives cross-feed to the work. The table is mounted over the saddle and it can be adjusted cross-wise. The table and saddle is provided with measurement reading and clamping mechanisms. A separate motor supplies power for the movement of table and saddle.

Spindle Head:

It slides in front of the column. It houses drive gear box, quill and feed gear box for the spindle. An indicator device is provided on spindle head, to measure the boring depth accurately. The driving mechanism provided to it is capable of giving speeds ranging from 300-1500 revolutions per minute. The quill is attached to it. which slides in the housing.

Column:

It is a hollow vertical structure. The colunm is provided with vertical guideways and it supports spindle head. The spindle head slides on the vertical guideways of the column. It houses the counter weights, to balance the spindle head.

These machines are characterized by,

1. Provision of highest accuracy through rigidity.

2. Locating and spacing holes by accurate measuring of distance.

3. Low thermal expansion.

A jig boring machine is visually similar to the vertical milling machine but not in case of operation and accuracy. To avoid deflections and vibrations, the spindle and other components of the machine are made extremely rigid. Antifriction bearings are used to run the spindle and housings of the spindle are made of invar to avoid its expansion during working at various temperatures. These machines are operated at temperature controlled rooms to avoid inaccuracy in the machine and work.

Types of Jig Boring Machine

The jig boring machines are classified into two types. They are,

Vertical Milling Machine Type:

This machine is visually similar to vertical milling machine it consists of a spindle, column, bed, work table. The spindle is arranged in the vertical axis and the work table is mounted on the bed in front of the column. The table can be moved in parallel, perpendicular and combined directions with respect to column face.

Planer Type:

This machine is designed in such a way that it consists of vertical columns on both sides of the work table which is mounted on the base. The table can be moved to and fro for adjusting the work. A cross rail is arranged on two vertical columns in the form of a bridge and the spindle is mounted on it. In this machine, the movements of the table (longitudinal) and spindle along with cross rail (cross) are used to locate the hole.