The enclosure of the motor serves two purposes :

- It provides the protection to the persons against the undesirable contacts

- To protect the parts and windings of the motor from the dangerous atmospheric factors such as fumes, dirt, dust, chemical gases, rats, cockroaches and other insects.

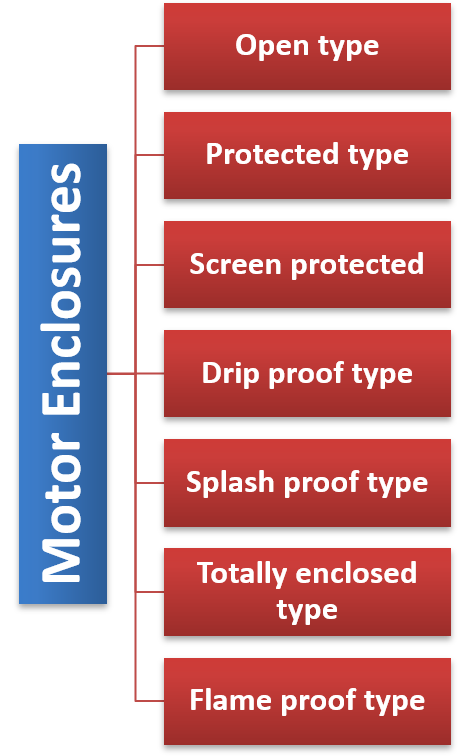

Types of Motor Enclosures

But the enclosure also blocks the natural air to enter into motor which prevents the natural cooling. Hence choice of enclosure is important for the motors. The various types of enclosures used are,

- Open type: This is used for large machines. It does not protect machine from atmospheric conditions. The suitable rail guards are provided to avoid the contact of persons to the rotating parts of motor.

- Protected type: In this ventilation is not prevented but access to live and moving parts is completely prevented.

- Screen protected: This does not protect motor from dangerous atmospheric conditions but prevents insects to enter into the motor. The openings provided for the ventilation are covered with screens of wire or expanded metals. It is widely used in industries with clean environment.

- Drip proof type: The ducts provided for ventilation are so protected by overhanging cowls that liquid drops failing vertically on the machine cannot enter the machine. It is used in damp conditions.

- Splash proof type: The openings for ventilation are so protected that liquid drops or dust particles will not enter the machine though strike the machine with force or splash. Thus it is suitable to operate machine in rainy conditions.

- Totally enclosed type: This type has solid frames and end shields without any openings for the ventilation. Thus only surface radiation helps for the cooling of the machine. This is used for any type of conditions as gives protection for all types of atmospheric conditions. It is used in coal handling plant, cement handling plants, paper plants etc. These are used for the machines up to 3 kW rating.

- Flame proof type: This type is suitable to prevent machine from vapour and explosion of gas which may lead to fire. The openings for the ventilation are made very long so that the flame can not reach to the motor surface. It is used in coal mines, petrochemical industries etc.