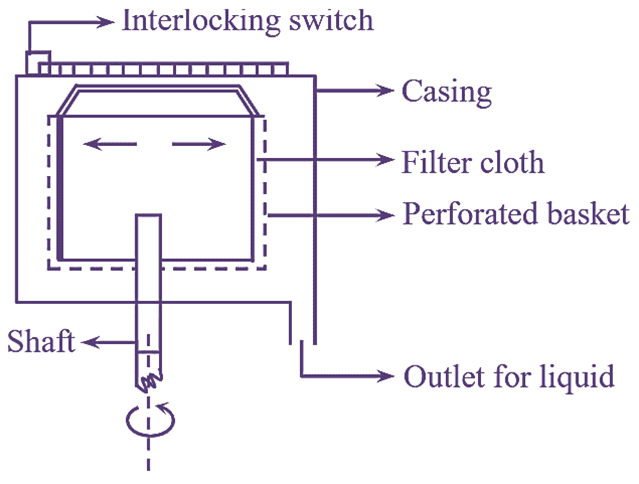

Figure 1: Perforated Basket Centrifuge.

Working Principle of Perforated Basket Centrifuge

Perforated Basket Centrifuge is based on the filtration mechanism, in which solids can be separated onto the porous medium due to difference in densities of solid and liquid phases. The basket contains a porous wall which is covered with a filter medium (i.e., canvas or metal cloth). During centrifugation, liquid phase passes through the porous medium while solid particles are retained in the basket.

Construction of Perforated Basket Centrifuge

It contains a perforated basket (see Figure 1), which may be made of any suitable metal like steel (or steel coated with vulcanite), copper or monel. These materials should be corrosion resistant. The diameter of basket is 0.9 m and its capacity is 0.085 m3. Perforation should be selected based on the size of solids to be filtered. If the size of perforations is bigger than the particles to be filtered, then filter cloth (or medium) is used as a lining inside the basket. The basket is mounted on a vertical shaft, rotated by a motor with the help of suitable power system (like water turbine, electric motor, pulleys). The starting power of motor is 5 kW and running power is 2 kW. A casing around the perforated basket is provided to collect the filtrate and to convey it to the outlet.

Working of Perforated Basket Centrifuge

Feed is introduced into the basket while it is stationary. The feed should be optimum so as to minimize the strain on the basket while centrifugation. The feed should be loaded in the basket in a proper manner. The basket is operated at 1000 rpm. It requires high power for starting i.e., 5 kW speed, but the power required for running is small i.e., 2 kW. Due to centrifugation, the solid particles get retained on the porous medium, while the liquid passes through the membrane and is collected at the discharge. The cake that is formed is made to dry by spinning it within the basket. When the drying is complete the motor is switched off, the cake can be separated by cutting it with a blade which is then manually collected and unloaded.

Advantages of Perforated Basket Centrifuge

- Very compact and occupies less space.

- It can separate solids from slurry containing high proportion of solids.

- Highly viscous liquid can also be centrifuged.

- The product obtained has very low moisture content compared to the products of filtration.

- It separates the dissolved solids while in the thermal drying process, the dissolved solids cannot be separated.

- The centrifugation process is rapid

Disadvantages of Perforated Basket Centrifuge

- The operation is complicated.

- It is a batch operation, so continuous operation is not possible.

- The centrifuge cannot be used for continuous operation because it undergoes large amounts of stress.

Applications of Perforated Basket Centrifuge

- Separation of drug crystals from the mother liquor.

Example: Aspirin.

- Removal of undesirable solids from liquids.

Example: Separation of precipitated proteins from insulin.

- The centrifuge is useful for separating and drying crystalline solids which results in a free-flowing product.

Example: Sugar Crystals.