In the resistance welding process, a heavy current is made to flow through the joint to be welded. The resistance of the joint generates I2R loss causing heat which melts the metal joint and causes fusion of the joint.

Types of Resistance Welding

Butt Welding

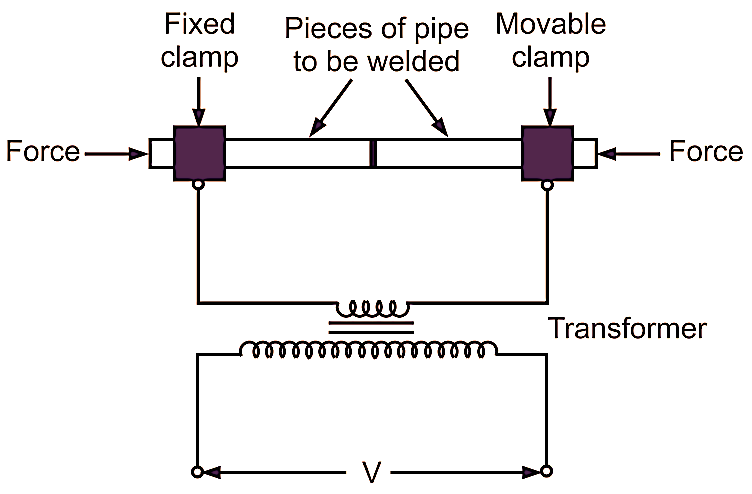

Figure 1: Butt Welding.

Rods, pipes and wires are welded by this method. As shown in Fig. 1 there is a transformer, across secondary of the transformer two pieces of metal to be welded are held. The two pieces are held in clamps. One clamp is fixed and other is movable. The pieces of pipe are made to touch each other and force/pressure is applied through springs. When supply is given to transformer, current passes through the pieces of pipes and sufficient heat is developed at the joint causing welding at the joint.

Flash Butt Welding

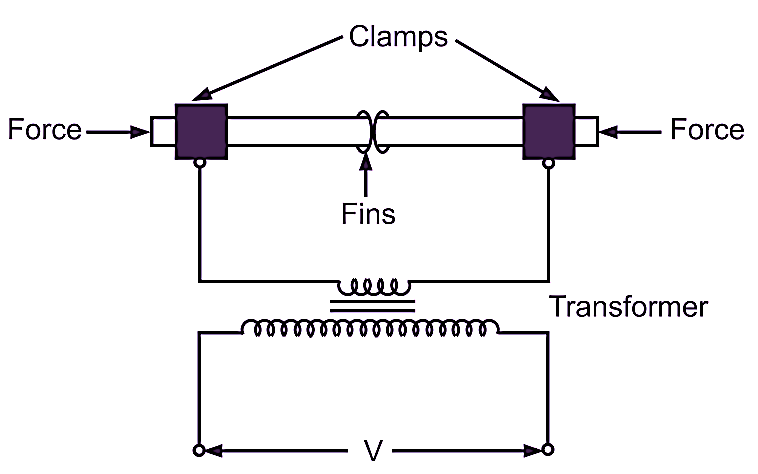

Figure 2: Flash Butt Welding.

This is a modification of butt welding. The ends of the pipe to be welded are held together with a little force/pressure applied to them. Arcing at the joint is allowed to take place. This removes any unevenness at the joint. A weld having a fin around the joint is obtained (Refer Fig. 2). The fin can be easily removed. Two dissimilar metals can be effectively welded with this method. This welding method is faster than other methods.

Spot welding

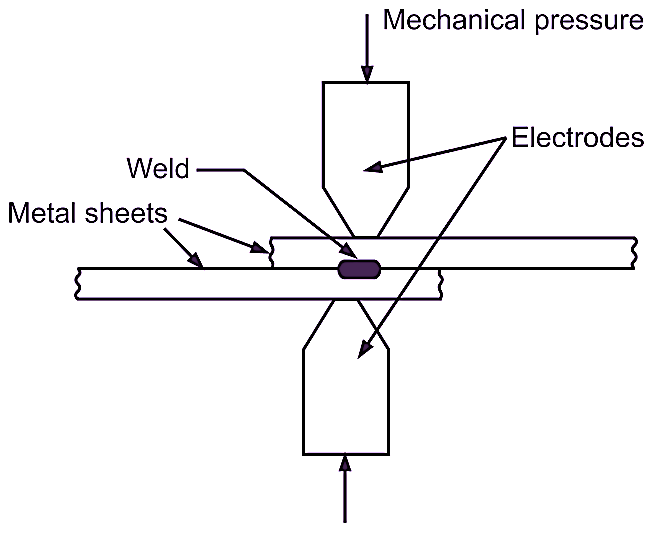

Figure 3: Spot Welding.

In spot welding, the welding is done at certain points on metallic sheets. The pieces to be welded are held between the two electrodes as shown in Fig. 3. When current passes through the electrodes, a spot weld is produced between the sheets.

Projection Welding

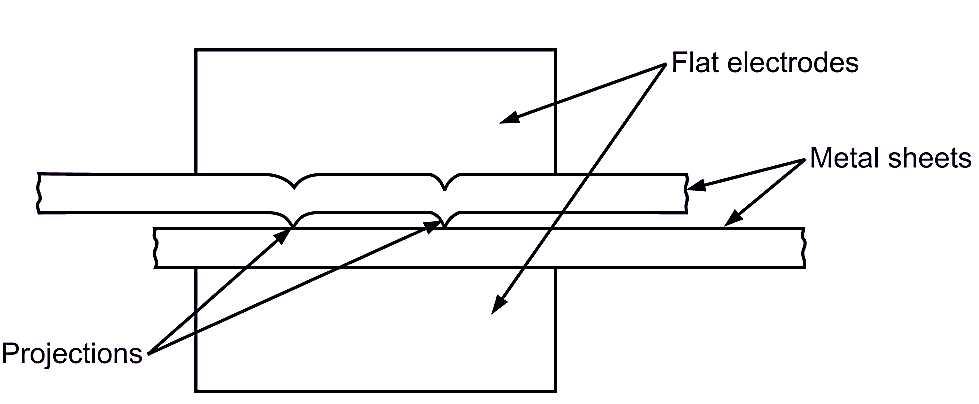

Figure 4: Projection Welding.

It Is a modified form of spot welding. The electrodes used are flat and not pointed as in the case of spot welding (Refer Fig. 4). Projections are made on one sheet so that heat is concentrated in that region. When current is passed through the electrodes, the current density and pressure required are less, hence electrode life is more. The welding automatically takes place only at the projections.

Seam Welding

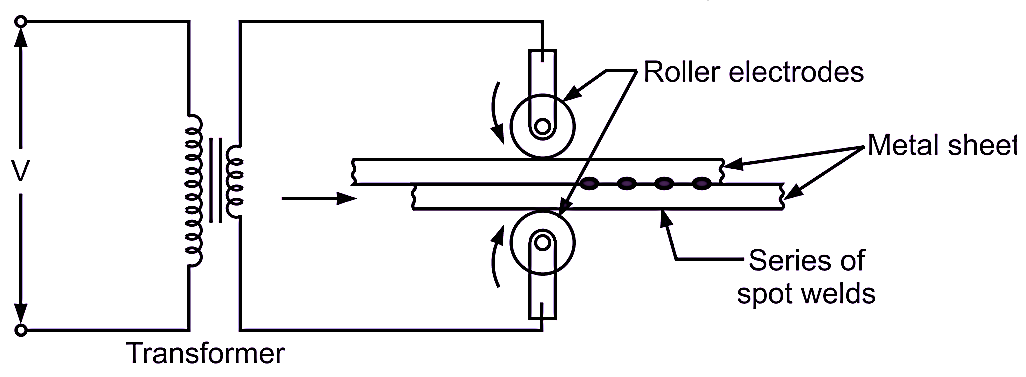

Figure 5: Seam Welding.

It is similar to spot welding. In seam welding, a series of spots is produced by roller electrodes, as shown in Fig. 5. Two sheets are passed under the two rolling electrodes. Depending upon the number of welding current pulses per second and speed of electrodes, a series of spot welds Is obtained.

Energy Storage Welding / Percussion Welding

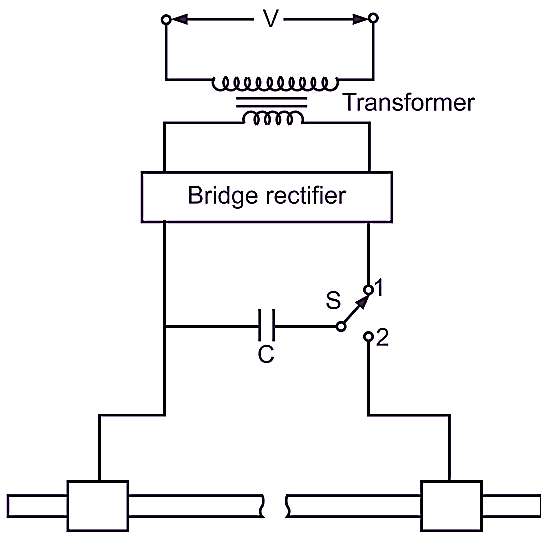

Figure 6: Energy Storage Welding.

Welding is obtained by discharging the stored energy in the capacitor. As shown in Fig. 6, it consists of a bridge rectifier, capacitor, switching arrangement. The pieces to be welded are kept at a certain distance apart (1.5 mm). Switch ‘S’ is put on position 1. So capacitor gets charged through the bridge rectifier. When S is put on position 2 the capacitor discharge takes place causing formation of arc between the two pieces. The pieces are heated up at the gap and fused together. Thus welding is obtained.

Applications of Resistance Welding

| Type of Resistance Welding | Applications |

| Butt welding | For welding rods, tubes, wires. |

| Flash butt welding | For welding, tubing, bars, rods, forgings, fittings used in automotive and aircraft products, refrigerators, welding of band saw blades. |

| Spot welding | For welding components made from plates (10 mm to 12 mm in thickness). For fabricating or joining sheet metal structure. |

| Projection welding | Used for mass production work e.g. welding of refrigerator, condensers, crossed-wire welding, refrigerator racks, granites, grill etc. |

| Seam welding | Used for welding of pipes, conduits, tanks, transformers, refrigerators, gasoline tanks, various types of containers. |

| Energy storage welding. | Used for welding different metals e.g. copper to aluminium or steel, cast iron to steel, |