The working principle of wire EDM is same as that of conventional EDM except that it uses a small diameter wire (about 0.02 – 0.3 mm) as electrode and deionized water as dielectric fluid. A pulsed D.C supply is connected to the ire and the component. The component material is melted due to heat generated from the spark as in case of conventional EDM. In this machining method, a predefined gap between the tool (wire) and the component is maintained with the help of a CNC positioning system. It is mainly used for machining of complicated shaped components.

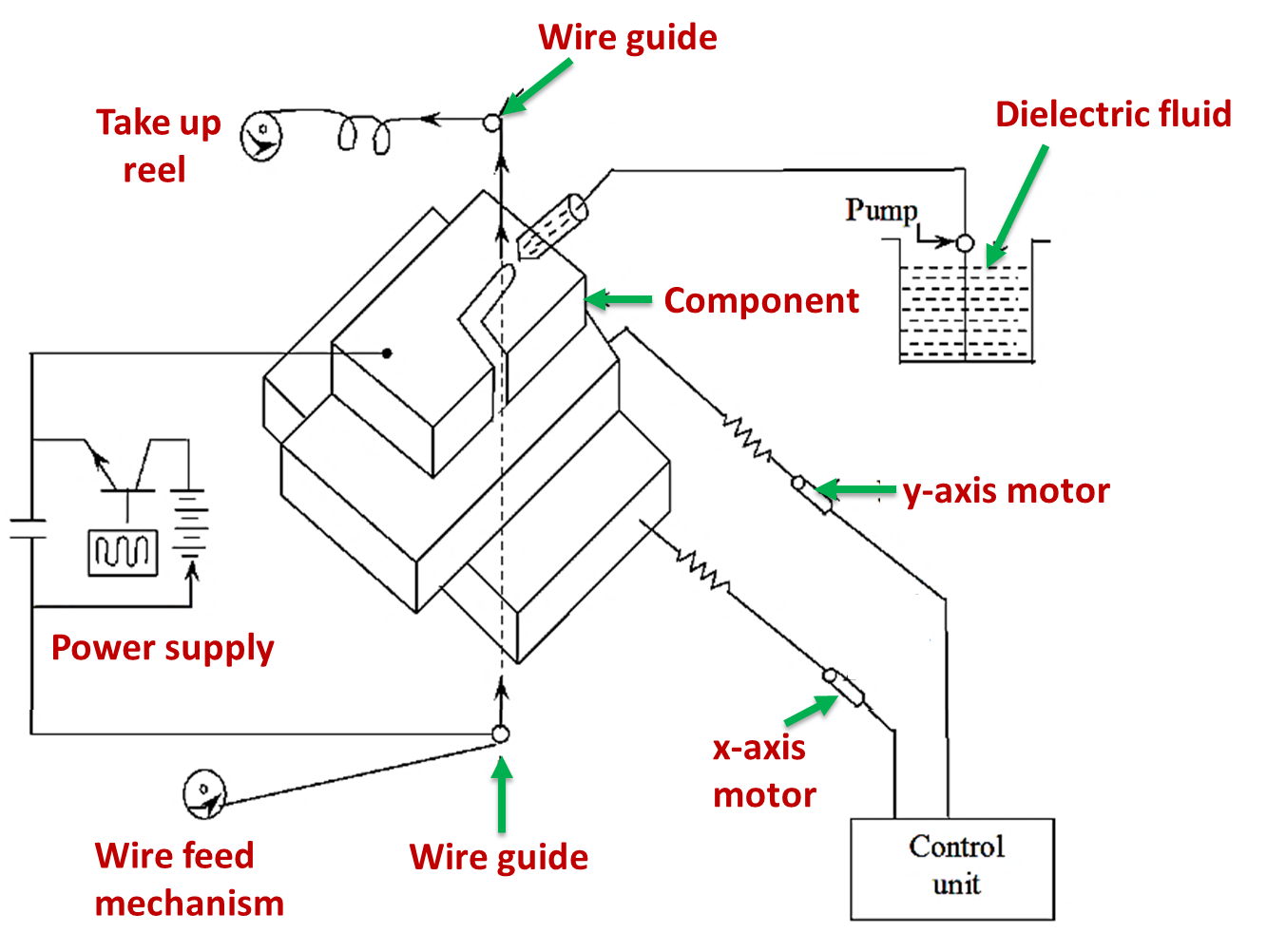

Figure 1: Wire EDM

Construction of Wire EDM

The primary elements of wire EDM (see Figure 1) system are as follows.

- Power supply system

- Dielectric system

- Positioning system

- Wire-drive system

Power Supply System

The power supply system of wire EDM differs from conventional EDM only in two parameters i.e., pulse frequency (1 MHz) and current carrying capacity of wire (< 20 A). This results in reduced size of cavity and hence better surface finish is obtained.

Dielectric System

In wire EDM process, deionized water can also be used as dielectric fluid instead of kerosene in conventional EDM. The advantages of water as dielectric fluid are

- Ease of availability

- Desirable thermal properties

- Low viscosity

- Pollution free operation

- High MRR

- Better surface finish

- Efficient flow properties.

Since, the Tool Wear Rate (TWR) is higher, the wire cannot be reused. The effective way of supplying dielectric is by providing a stream of deionized water along the axis of the wire. The cost of dielectric can be reduced by reusing it after thorough filtering. The filteration should be carried out with a 5 µm disposable filter paper. Special additives are added to the fluid to prevent rust formation.

Positioning System

The positioning system of wire EDM comprises of two axes CNC table. When the wire approaches the component or any other material clogging the gap causes short-circuit, this system will be effective enough to sense the condition in an adaptive control mode- The operating conditions are regained instantaneously.

Wire-drive System

The principle requirements of this system is to provide fresh wire to the machining and to maintain the required tension such that the supplied wire is straight. As long as the supplied wire is straight with required tension, the taper, wire breakage and vibrational marks are reduced. The wire in this process is guided by wire guides (usually of diamond or sapphire) and it is passed through a series of tensioning rollers before it rolls in the take up reel.

Applications of Wire EDM

Wire EDM possesses a wide range of applications. Some of them are as follows,

- Fabrication of different types of dies such as extrusion, progressive, blanking etc.

- Complex shaped components can be easily machined.

- Machining of components which requires close tolerance.

- Machining of narrow slots, keyways and mold components.

- Cutting of hardened materials such as polycrystalline diamond (P.C.Ð), cubic boron nitride (C.BN), carbides, etc.

- Cutting of materials such as titanium, castalloys etc., which are difficult from other machining methods.

- Tools used in forging and injection moulding operations.

- Delicate and thin sized components which are susceptible to tool pressure.

- Machining of medical and dental instruments.

- Manufacturing of c.omponents used in electronic, defence and aerospace industries