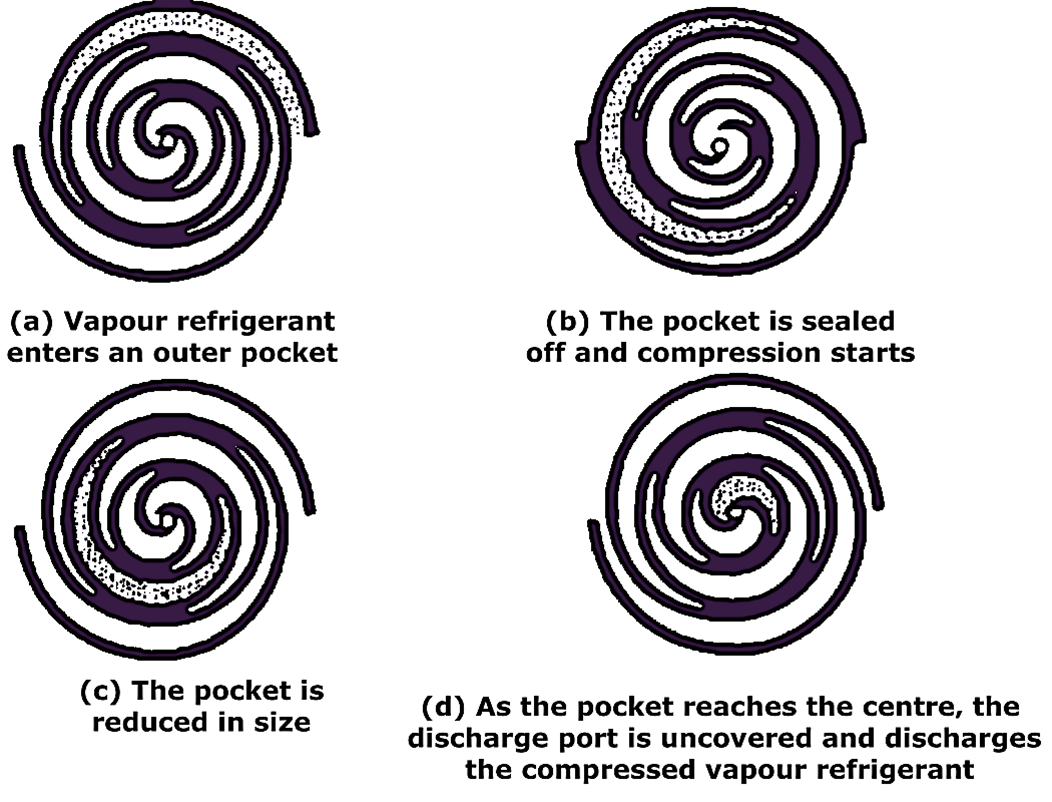

The scroll is involute spiral fixed on a plate. This compressor has two spirals as shown in Fig. 1. It has no valves. It is also called as constant volume ratio compressor. The two spirals are in mesh forming gas pockets, which reduce in volume progressively. One spiral s stationary and the other spiral orbits around the stationary spiral, (For example: The earth orbits around the sun) to complete the cycle. The suction is at the outer periphery and discharge is at the centre of stationary scroll. As all pockets between the scrolls have gas in various stages of compression, therefore, the flow is continuous with least pulsations, which leads to high volumetric efficiency. Refer to figures 3.7 (a), (b), (c) and (d) along with the description to understand the compression of vapour refrigerant using scroll compressor.

Fig. 1: Working of scroll compressor

Advantages of Scroll Compressors

- Reliability: With fewer moving parts, the scroll compressor provides higher reliability.

- Energy Efficiency: The scroll compressor is at least 10

- High durability.

- Less noisy operation.

- Good system performance.

- Better starting ability.

Disadvantages of Scroll Compressors

- They are not easily repairable. Therefore, they may have to be replaced.

- They cannot be dissembled for maintenance.

- Low capacity.

- Relatively expensive.

Applications of Scroll Compressors

- Nowadays, scroll compressors are more frequently used in:

- Residential air conditioners.

- Car air conditioners.

- Refrigerated truck transportation.

- Heat pumps.

- Bulk milk cooling.

- Refrigerated marine containers.

The scroll compressor (in the near future) might replace the reciprocating compressor in small refrigeration plants.