Hermetically sealed compressor is mounted directly on shaft of motor. The assembly of compressor and motor is hermetically sealed in a welded steel shell. The motor is cooled by the refrigerant itself, either by vapour refrigerant being drawn into the compressor from suction line or by liquid refrigerant being drawn from liquid line, starting from condenser outlet. This eliminates the need of shaft coupling and external shaft seal, which are used in reciprocating compressor. Hermetically sealed compressor is employed in domestic refrigerators, deep freezers and window air conditioners.

A compressor is said to be hermetically sealed compressor, when the compressor and motor operate on the same shaft and both are enclosed in a common casing. These types of compressors eliminate the use of crank shaft seal, which is necessary in open type compressors in order to prevent leakage of refrigerant. In case of open type compressor like reciprocating compressor, a shaft seal fitted on the crankcase remains a permanent source of trouble and after some period of service, it tends to leak requiring constant attention. Since a common user is unable to pay the required attention, a hermetical y sealed compressor is used in small refrigeration systems like domestic refrigerator, window air conditioner etc.

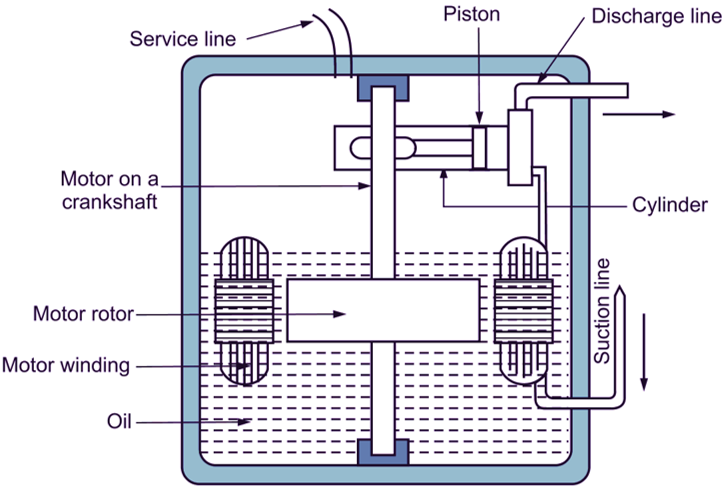

Construction of Hermetically Sealed Compressor

The compressor and motor mounted on the same shaft are enclosed in a casing. Suction and discharge lines are extended inside the casing. A service line is also provided for charging of refrigerant and changing of lubricating oil. The power is supplied to three terminals of the motor winding through a relay. The relay cuts off starting winding after a start-up, leaving running winding in circuit. The relay has an overload protector (OLP) also.

Fig. 1: Hermetically sealed compressor

Working of Hermetically Sealed Compressor

Compressor and motor operate on the same shaft in a common casing (i.e. housing). As the motor shaft rotates, piston starts reciprocating inside the cylinder. The low temperature and low pressure vapour refrigerant from the evaporator is sucked into the compressor shell. The refrigerant sucked in the compressor shell does not get admitted directly into the cylinder, but instead, it is circulated in the shell around the motor, so that, the motor can be cooled. Thus, the suction vapour refrigerant is used to cool the lubricating oil as well as winding of the motor. Then, the sucked vapour refrigerant enters into the cylinder and gets compressed, thereby increasing its pressure and temperature. At the end of discharge stroke of the piston, the high pressure refrigerant is discharged, through the discharge line. As the motor is enclosed, it heats up the oil bath in the casing. Therefore, suction vapour refrigerant is used to cool the motor. In some units, a special oil cooling loop is provided from the condenser. As the unit is sealed, its life is very long. Also, there is reduction in noise during operation. The use of capillary tube as an expansion device was made possible only with the use of sealed unit, because use of very small diameter capillary tube was limited due to tendency of refrigerant leakage. Hermetically sealed units are now available up to 10 TOR capacities and are found in refrigerators, water coolers, deep freezers, window/split air conditioners and even in package air conditioners. The sealed unit has no easy access and needs to be cut and open for repairs. This difficulty is overcomed with the development of a semi-hermetically sealed unit. In hermetically sealed compressor, compressor is in the form of welded steel shell, whereas, in semi-hermetically sealed compressor, top cover is bolted to compressor housing. This top cover is also called as screwed cover. Due to the bolted construction, parts of compressor become accessible after removing the top cover. Therefore, repair or servicing can be done. Semi-hermetically sealed units are now-a-days available in large capacities even up to 100 TOR.

Applications of Hermetically Sealed Compressor

- Domestic refrigerators.

- Window air conditioners.

- Water coolers.

- Home freezers.

- Split air conditioners.

- Deep freezers.

- Small capacity refrigeration and air conditioning units.

Advantages of Hermetically Sealed Compressors

- The leakage of refrigerant is completely prevented.

- Less noisy.

- Less vibration.

- Compact, so requires small space.

- The lubrication is simple as the motor and compressor operate in a sealed space with the lubricating oil.

- The power required per tonne of refrigeration is less than that required for open type compressor.

- As both, the motor and compressor are enclosed a common casing, it eliminates the need of crank shaft seal.

- Long life.

- Portable as they can be moved easily from one place to another place.

- Less maintenance.

- Easy installation.

- The suction and discharge connections are available externally.

Disadvantages of Hermetically Sealed Compressors

- Not easy for maintenance, because the moving parts are not accessible. The welded joints need to be broken and open for repairs.

- Separate vacuum pump is required for evacuation and charging of refrigerant.

- The lubricating oil may mix with the refrigerant and can deteriorate the quality of refrigerant.

- Presence of moisture in the refrigerant may harm the winding of motor.

- Due to difficult maintenance activity, existing hermetically sealed compressor under maintenance is replaced by new one, instead of repair. Therefore, when service period (life) is considered as parameter for selecting suitable compressor, the refrigeration system using this compressor is said to be costlier,