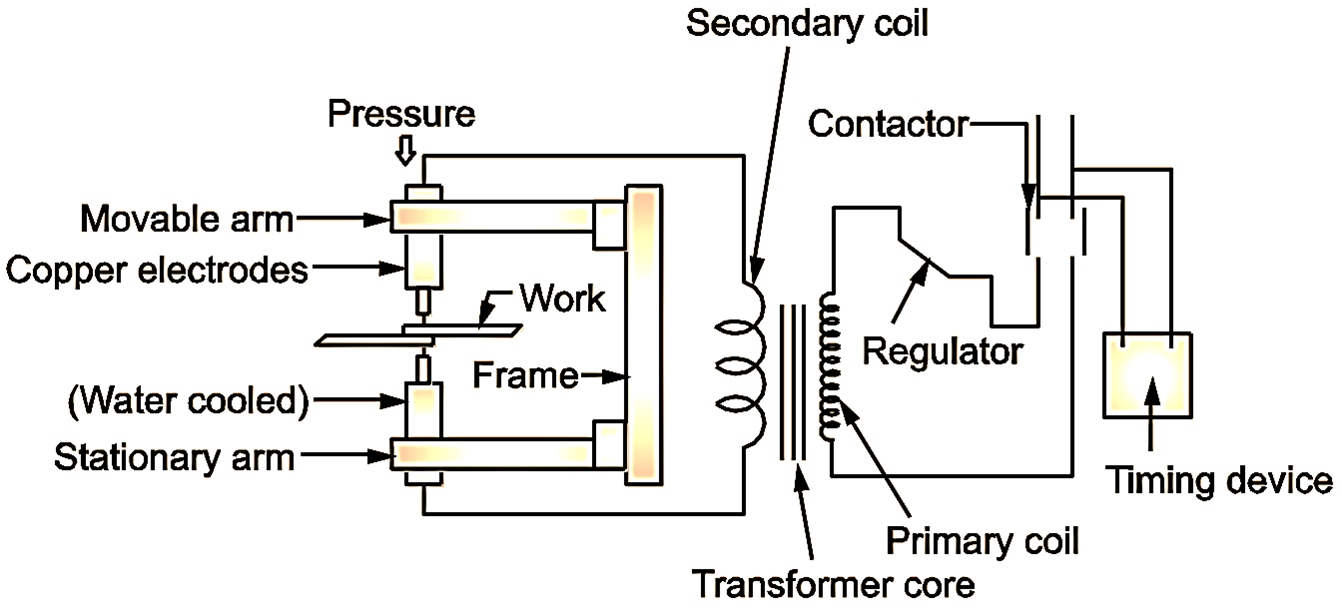

The spot welding method is used to weld on spot. Sheets to be welded are held between electrodes made of copper or alloy of copper or tungsten. This process is used to join overlapping sheets or plates. The sheets to be welded are held between the electrodes. The pressure is applied and the current is passed through the metal.

There are three stages in making the weld:

- The pointed electrodes are brought together against the overlapping sheets of metal and pressure is applied before current is passed. Electrodes are made of copper or alloy of copper or tungsten.

- Heavy current at low voltage is then passed through the metal for predetermined time. Sheets get heated to the welding temperature at the area of contact of the electrodes. The pressure between the electrodes squeezes the metal at one spot.

- The current is turned OFF, but the pressure is maintained. The weld is completed due to the pressure, while metal cools.

In order to avoid overheating of the electrodes, arrangement for cooling the electrodes by circulating water may be provided.

(a) Electric circuits for a spot welding machine.

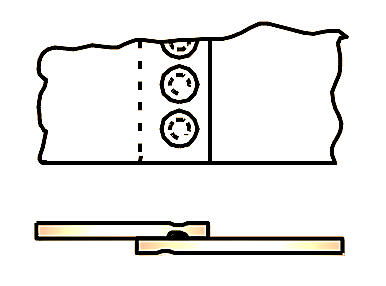

(b) Spot weld

Fig. 1: Spot welding

The surface of metal sheets joins at the spot under the electrodes as shown in Fig. 1 (b).

Advantages of Spot Welding

- In this welding, process is free from fumes and spatter.

- Generally, it has no maintenance or no skilled persons are required for maintenance.

- No skilled persons are needed to operate the spot welding.

- Welding cost is minimum.

Limitation of Spot Welding

1. Continuous, pressure-tight welds can not be made.

Application of Spot Welding

The spot welding is widely used for welding parts of automobiles, airplanes, steel cabinets, furniture, refrigerators etc. The process is rapid and is applicable to ferrous and non-ferrous ductile metals and their alloys. This method is employed for mechanical strength rather than water or air tightness.