Strain gauge Load cell is an application of wire type bonded strain gauge. Load cell is an electro-mechanical transducer. These cells convert Load or force (P) into electrical output, which is provided by the strain gauges. It translates the change in force or strain into change in voltage. This output can be connected to various measuring instruments for indicating, recording and controlling the weight or force. Load cells are excellent force-measuring devices, particularly for transient and non-steady forces.

Construction of Strain Gauge Load Cell

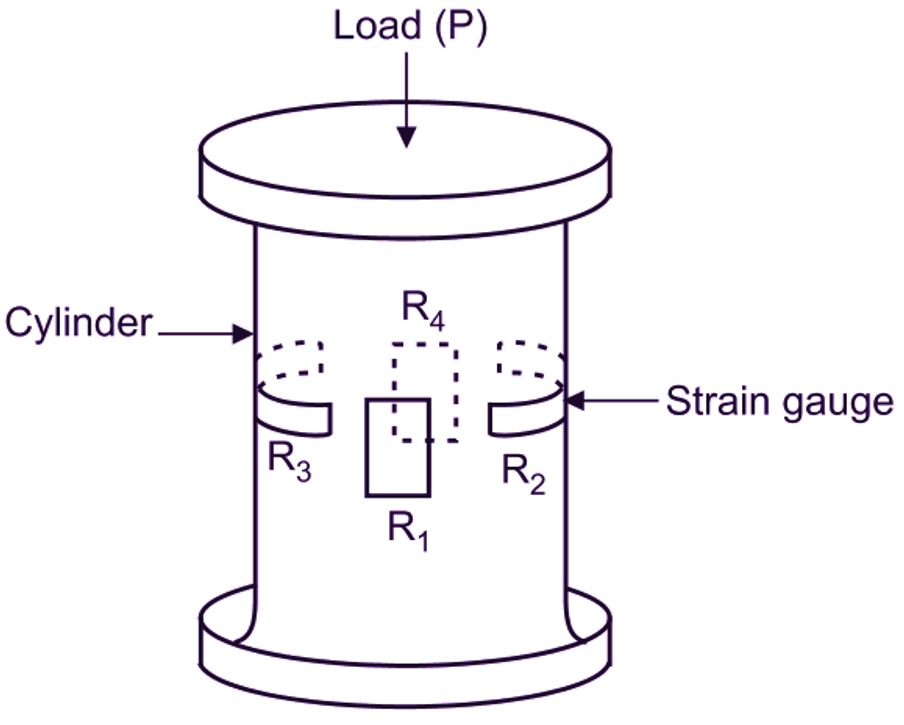

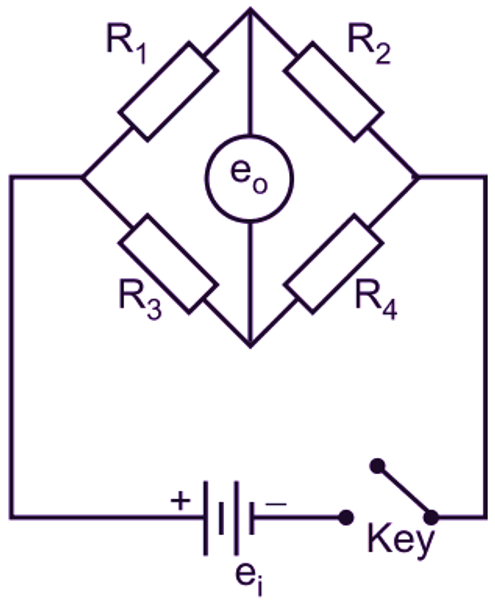

Fig. 1 (a) shows a simple strain gauge load cell. Load cell consists of a steel cylinder, on which, four identical strain gauges are mounted. The gauges R1 and R4 are along the direction of applied load (i.e. vertically) and the gauges R2 and R3 are attached circumferentially to gauges R1 and R4. All the four gauges are connected electrically to the four arms of a Wheatstone bridge circuit.

(a) Arrangement of Strain Gauge Load Cell

(b) Electric Circuit

Fig. 1: Strain Gauge Load cell

Working of Strain Gauge Load Cell

When there is no load on the cell, all four strain gauges will have same resistances (R1 = R4 = R3 = R2). It means, Wheatstone’s bridge is in balanced condition, and galvanometer shows zero output voltage. On the application of a compressive load to the unit, the vertical gauges (R1 and R4) undergo compression (i.e. decrease in length causing negative strain). Due to decrease in length, resistance decreases. At same time, the circumferential gauges R2 and R3 undergo tension (i.e. increase in length causing positive strain). Due to increase in length, resistance increases. As a result of change in resistances, Wheatstone’s bridge gets unbalanced. Thus, an output voltage obtained is a measure of applied load. Refer Fig. 1 (b).

Advantages of Strain Gauge Load Cell

- Load cell is small and compact in size.

- Accuracy is very good.

- It has good sensitivity and low hysteresis.

- It is less expensive.

Disadvantages of Strain Gauge Load Cell

- Its performance is affected by non-axial force.

- It requires temperature compensation network.

- Excessive stress or force may damage load cell permanently.

Applications of Strain Gauge Load Cell

- Force dynamometer,

- Crane load monitoring, and

- Road vehicle weighing devices.