Centrifugal clutch is a type of friction clutches, which uses the property of friction existing between two contacting surfaces, like single plate and multi-plate clutches. But, the construction and working of centrifugal clutch eliminate the need of circumferentially or radially mounted clutch springs.

Working Principle of Centrifugal Clutch

Centrifugal clutch works on the principle of centrifugal force, which states that, “magnitude of centrifugal force increases along with increase in speed and vice-versa.” Centrifugal clutches engage and disengage with the flywheel based on the magnitude of centrifugal force, which depends upon speed. Therefore, driven member automatically engages with the driving member after attaining a particular speed. Hence, a clutch pedal is not required for drive engagement and disengagement. Therefore, these clutches are used with automatic transmission.

Construction of Centrifugal Clutch

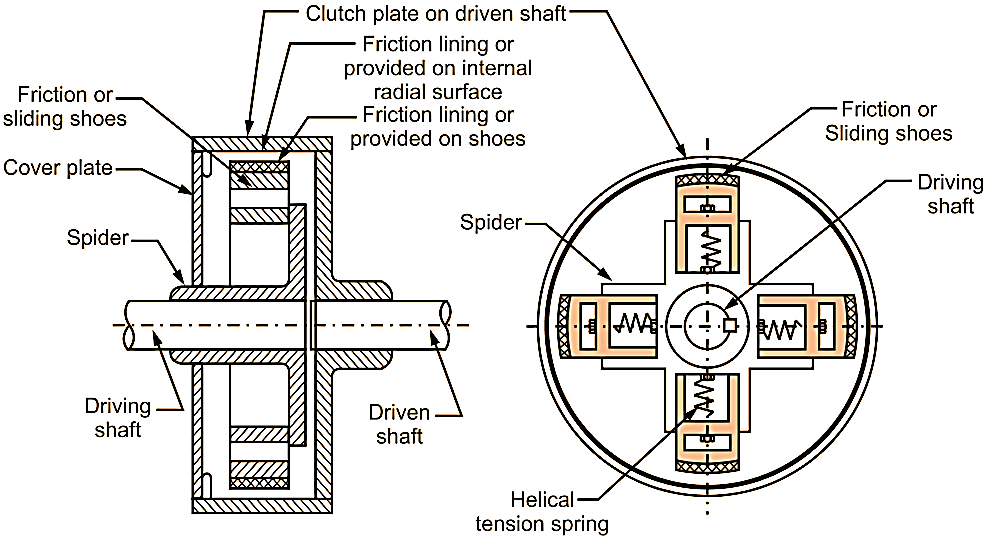

Fig. 1: Centrifugal Clutch

Spider

Spider is a special hub rigidly mounted on the driving shaft. Spider has four equi-spaced radial guides keyed to the driving shaft. The friction shoes are connected to spider through springs.

Clutch plate

Clutch plate is cylindrical in shape and has friction lining on its internal radial surface. The clutch plate is rigidly connected to the driven shaft and does not have any splines on the shaft.

Friction shoes (sliding shoes)

Friction shoes are covered with frictional material at their outer side. Friction shoes are sliding fit into the spider with adequate clearance for sliding action. Due to the clearance provided, friction shoes can slide radially in guides of spider. Therefore, friction shoes are also known as sliding shoes.

Drum (Cover Plate)

Entire assembly of spider and shoe is enclosed in a co-axial drum, which is mounted on the driven shaft. Drum is also known as cover plate. Housing of drum acts as a safety cover against any accidental damage.

Working of Centrifugal Clutch

Fig. 1 shows the centrifugal clutch in stationary or disengaged position. The friction shoes are held back by the helical tension springs. Therefore, friction shoes do not have any contact with the clutch plate, in this disengaged position.

Process of engaging clutch

When driving shaft starts rotating, then spider and friction shoes also start rotating at same angular speed. Due to rotary motion, a centrifugal force is exerted on friction shoes in radially outward directionDue to this centrifugal force, friction shoes tend to slide away from the centre of driving shaft. When the speed of spider increases upto a value, at which, centrifugal force becomes more than the spring force. This exceeding centrifugal force overcomes the spring force, due to which, shoes are extended towards the inner surface of clutch plate and get pressed against the clutch plate. With further increase in speed, the engagement continues and increases upto 100

Process of disengaging clutch

When the vehicle speed is lowered (brake applied), spring force overcomes the centrifugal force and the shoes are pulled back towards the centre of shaft. Thus, power drive to the clutch shaft gets disengaged.

Advantages of Centrifugal Clutch

- It eliminates the need of clutch pedal.

- It provides ease of driving due to absence of clutch pedal.

- Simple to operate.

- Drive engagement is very smooth.

Disadvantages of Centrifugal Clutch

- Low torque transmitting capacity.

- It results in one-sided wear of friction lining.

- The spring tension loosens over a working period of time.

- High cost.

Applications of Centrifugal Clutch

- Lower torque transmitting capacity applications.

- Automatic or semi-automatic transmission systems.

- Typical applications are: Mopeds and Small passenger cars.