Multi-plate clutch is an extension of single plate clutch and works on the same principle as that of single plate clutch. Multi-plate clutch has multiple numbers of frictional and metal plates. This arrangement of multiple frictional and metal plates provides increased friction surface area, due to which, torque transmitting capacity of clutch increases. Therefore, multi-plate clutch is widely used in many applications.

In addition to high torque transmission capacity, additional advantage of multi-plate clutch is its compactness in size. Therefore, multi-plate clutch is useful in applications, where space availability is limited.

Construction of Multi Plate Clutch

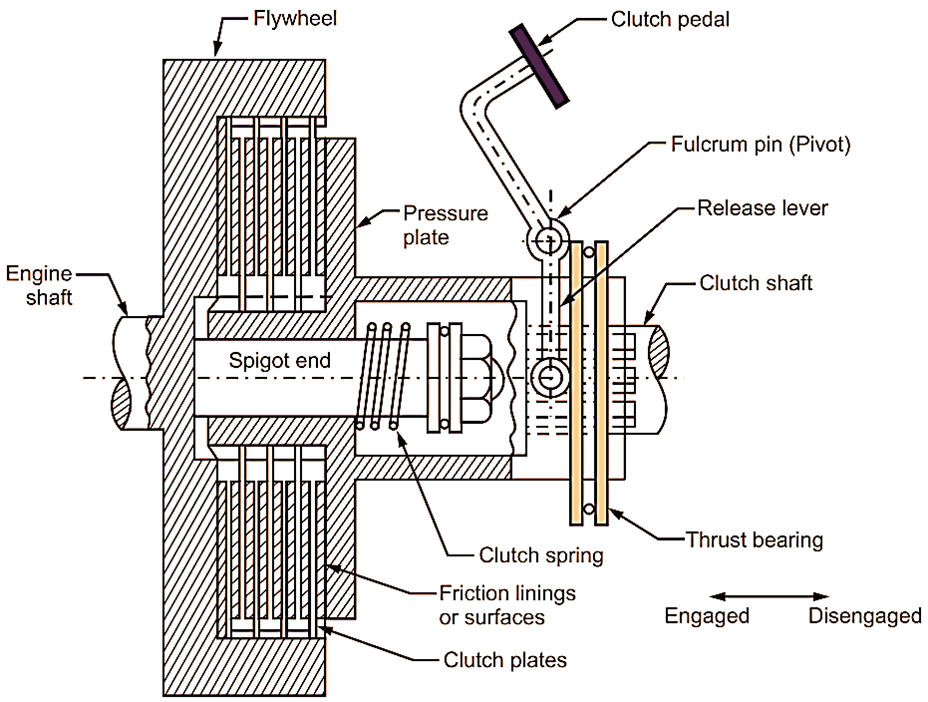

Fig. 1: Multi-plate Clutch

Flywheel

Flywheel consists of a cylindrical wheel bolted to the engine crankshaft. Friction surface is provided on the vertical side of flywheel. The cylindrical portion of flywheel contains internal teeth for engaging with outer teeth type clutch plates.

Clutch plates

Two sets of clutch plates are used, i.e. one with outer teeth and other with inner teeth (Fig. 2).

(a) Outer teeth type clutch plate

(b) Inner teeth type clutch plate

Fig. 2: Clutch Plate Set

The outer teeth type plate engages with the inner teeth of flywheel. The inner teeth type plate engages with the splined clutch shaft.

Pressure plate

It is a heavy mass plate with a flat surface on its one side, which engages with the clutch plate.

Clutch springs

Clutch springs are axially mounted in between the clutch plate and pressure plate. These springs keep the clutch in engaged position, when the pedal position is up (i.e. free from effort, which is applied by driver during disengagement).

Release lever

Release lever is pivoted on fulcrum pin. Release lever is used to transmit motion of clutch pedal to pressure plate, when clutch pedal is pressed by driver for disengaging clutch.

Clutch shaft

Clutch shaft is connected to input shaft of gearbox. It is splined near the central hub, where, the clutch plates can slide.

Thrust bearing

Thrust bearing takes care of the axial load, which comes during sudden release of clutch springs, when it is in compressed state due to axial force applied by release lever at the time of disengagement of clutch.

Working of Multi Plate Clutch

To understand working of multi-plate clutch, let us consider following two cases:

When the clutch is engaged position

Fig. 1 shows multi-plate clutch assembly in engaged position. It means that, clutch pedal is not pressed by the driver. This condition is referred as Clutch Pedal Position-Up. When the clutch pedal position is up, the axial force offered by clutch spring ensures that, pressure plate is pressed against the flywheel (i.e. towards flywheel) with clutch plate being sandwiched between pressure plate and flywheel. Therefore, drive gets engaged and power is transmitted from flywheel to outer teeth type plate, further from outer teeth type plate to inner teeth type plate and then to the clutch shaft.

When the clutch needs to be disengaged

For disengaging the clutch, the clutch pedal is pressed by the driver. This condition is referred as Clutch Pedal Position-Pressed-Down. When the clutch pedal is pressed down, the release lever pulls the pressure plate away from the clutch plate against the axial force offered by clutch spring and thereby, compressing it. This loosens the frictional contact between the set of clutch plates and flywheel. Therefore, drive gets disengaged and power is not transmitted from engine to clutch plate and hence, clutch shaft.

Advantages of Multi-plate Clutch:

- Compact in overall size, hence it needs small space to accommodate.

- Higher torque transmission capacity.

- Smoother power transmission.

- Low rate of wear and tear.

- More durable.

Disadvantages of Multi-plate Clutch

- The complicated design of clutch plate set.

- Difficult for maintenance and servicing.

- Higher cost.

Applications of Multi-plate Clutch

- It is used, where high torque transmission is required. For example: Racing cars.

- It is used, where space availability is less. For example: Scooters, Motorbikes etc.