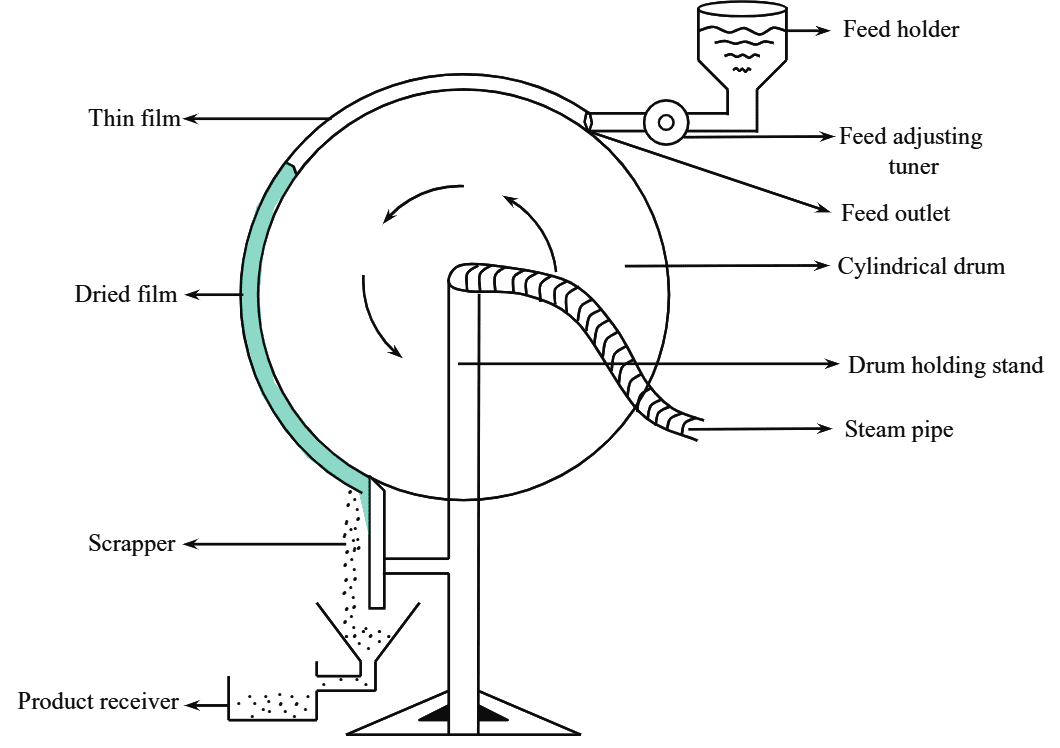

Figure 1: Drum Dryer.

Working Principle of Drum Dryer

In Drum Dryer, a hot drum is allowed to rotate to which a thin film of solution is applied. Heat transfers from the drum to the film (solution) by conduction, as a result of which drying is achieved. Steam is used as heating medium.

Construction of Drum Dryer

It consists of a cylindrical, hollow drum made up of metal. The drum is mounted horizontally on a stand and rotates on its longitudinal axis. A pipe is fitted at the center of the drum for passing steam. The drum has a smooth surface with a length of about 60 to 40 cm and a diameter of about 60 to 300 cm.

A feed holder is fixed at the top right position, it contains a feed outlet and a feed adjusting valve. The feed outlet also act as a feed spreader. A scrapper is attached at the bottom of the metal cylinder below which product receiver is placed.

Working of Drum Dryer

Initially the drum is heated by passing steam through the steam inlet (pipe provided) and then the drum is allowed to rotate. The drum rotates continuously along with continuous entry of steam. Its speed is adjusted to about I -10 rpm. The solution to be dried (feed) is placed into the feed holder and the rate of flow of the feed is adjusted with the help of adjusting valve. The solution spreads uniformly as a thin film on the surface of the drum. Drying occurs as a result of conduction (of heat) and the dried product is removed by the scrapper (at the bottom) and collected in a container. The drum rotates continuously because of which there is a continuous application of solution and its subsequent (frying. The film dries before the drum completes a single rotation i.e., the contact time of film with the drum is very less (only 7 – 15 seconds).

Advantages of Drum Dryer

- Suitable for thermolabile substances because it takes less time for dying.

- Equipment requires less space.

- High heat transfer coefficient.

- It can be operated continuously.

- Complete dying of product is achieved.

Disadvantages of Drum Dryer

- Skilled person is required to control the drum speed, feed application, film thickness etc.

- Cost of operation is more.

- Not suitable for salty solutions having less solubility.

- Drying of wet solids and crude drugs is not possible.

Applications of Drum Dryer

- Solutions of starch, ferrous salts etc., can be dried.

- Suspensions of yeast, kaolin, zinc oxide etc., can be dried.

- Slurries can also be dried.

Modifications of Drum Dryer

- Rotatory drum dryer can be operated under vacuum by enclosing both drum and feed inlet. This modification is called as vacuum drum dryer and is useful in dying thermolabile solutions. Also the solutions which are susceptible to oxidation can be dried.

- Sometimes the equipment (vacuum dryer) is installed with two drum (parallel to each other) and a single feed inlet for large scale drying.