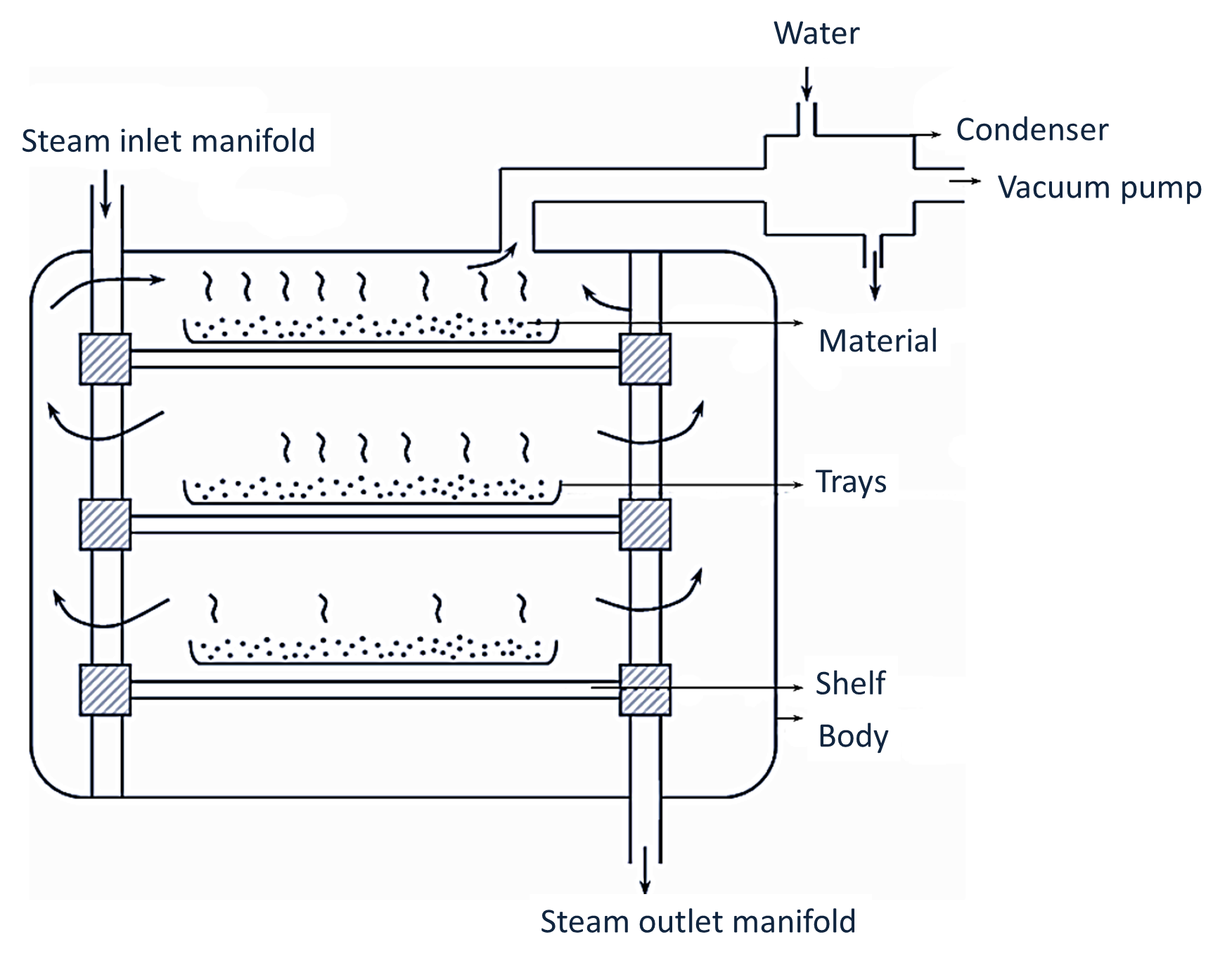

Figure 1: Vacuum Dryer.

Working Principle of Vacuum Dryer

Vacuum Dryer involves the indirect application of heat or steam to the material, tinder evacuated conditions i.e., vacuum is created inside the dryer. Under such conditions, the moisture evaporates at a temperature lower than its boiling point. Hence, drying occurs in a shorter period compared to normal tray dryer.

Construction of Vacuum Dryer

It consists of a rectangular metal body installed with shelves, above which heating trays are present (see Figure 1). Shelves are hollow internally and are held by vertical manifold (stands) on either side. An outlet is provided at the top of the dryer which is connected to the vacuum pump with a condenser in between. The steam inlet and outlet manifold are present at the top and bottom of the dryer respectively. Shelves and manifolds (vertical) are made up of suitable heat conducting material (such as copper) in order to facilitate better heat transfer.

Working of Vacuum Dryer

Trays are loaded with the material (which is spread uniformly) and placed onto the shelves. Dryer is rendered air tight by closing the door and vacuum is created (in the dryer) with the help of vacuum pump. Steam is passed through the inlet (steam inlet manifold) and is distributed throughout the shelves. As a result, the shelves get heated up and the steam (i.e., both condensed and non-condensed) is removed through the outlet provided. Instead of steam, hot water may also be used. Heat transfer takes place due to conduction and the water gets evaporated, at a temperature lower than its boiling point. Formed vapours are carried to the condenser, from which they are eliminated after condensation.

Advantages of Vacuum Dryer

- Drying time is reduced as it provides greater surface area for heat transfer.

- It is easy to operate.

- There is no loss of material.

- More efficient for valuable solvents.

- Can be operated at desired temperatures.

Disadvantages of Vacuum Dryer

- Labour cost is high.

- Low heat transfer coefficient.

- It has limited capacity and cannot be used for continuous process.

- Equipment is expensive when compared to simple tray dryer.

- Overheating of the material may occur.

Applications of Vacuum Dryer

- Vacuum dryer is used for drying thermolabile amid oxidizable substances.

- Hygroscopic and dusty materials can be dried.

- Used for obtaining porous products and friable dry extracts.

- It is used when toxic or valuable solvent is to be recovered.