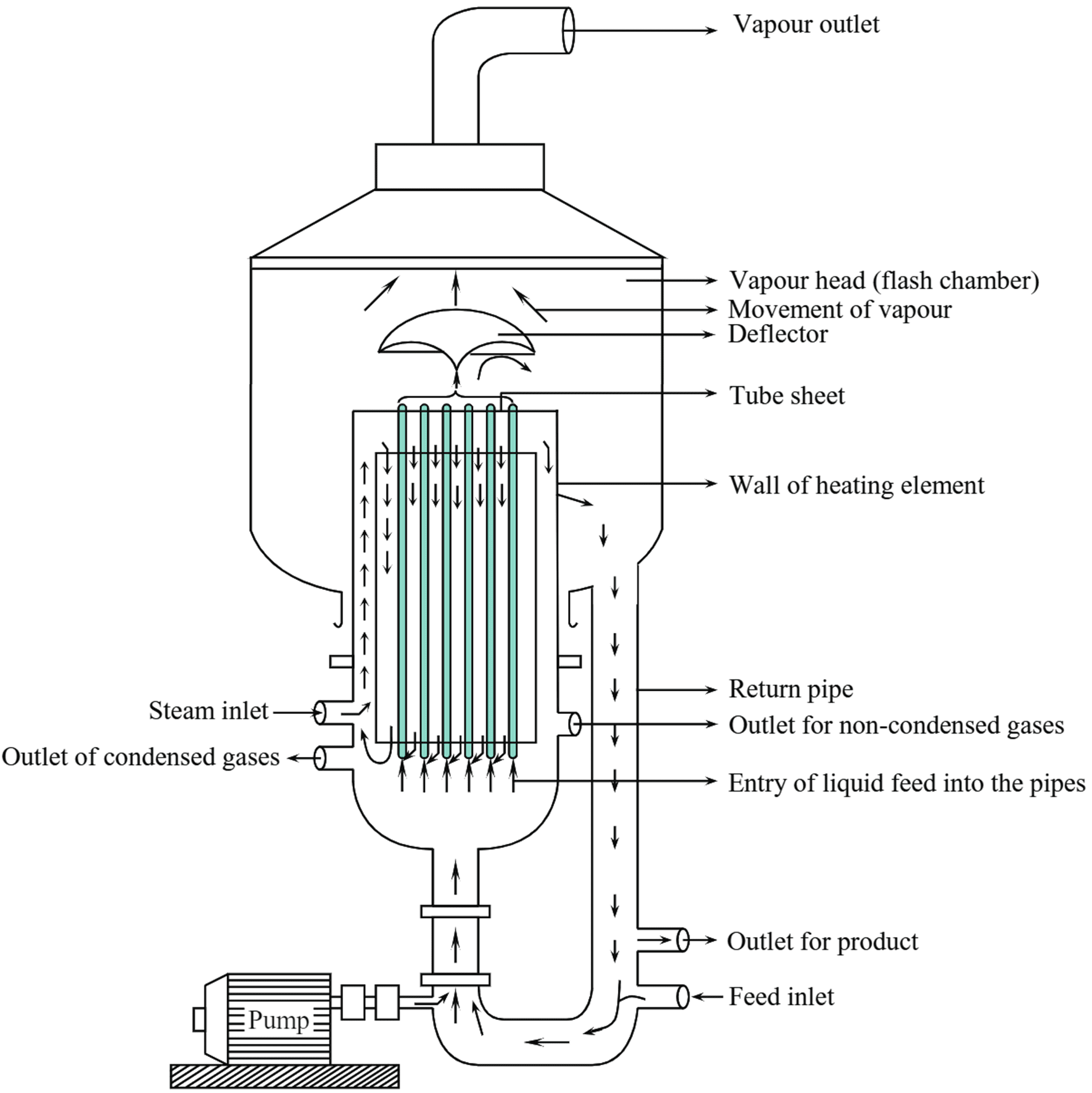

Figure 1: Forced Circulation Evaporator.

Working Principle of Forced Circulation Evaporator

The main principle involved in Forced Circulation Evaporators is forced circulation. Liquid feed is pumped into the evaporator at a velocity of 4-10 m/s from the bottom with the help of a pump. The rate at which the liquid is pumped is varied depending upon the proportion of solid particles present within the feed. The liquid is pumped through the tubes to reduce scaling during evaporation. When the liquid reaches the vapour head (flash chamber) of the evaporator, it gets subjected to flashing (sudden conversion of compressed liquid into vapour when released in a large area) which separates the liquid and the vapour. Vapours escape from the top of the evaporator chamber, whereas the concentrated liquid is again recirculated via the pump.

Construction & Working of Forced Circulation Evaporator

In these evaporators, the heating element is placed partly in the vapour head (flash chamber) of the equipment. This vapour head is connected to the pump via a return pipe. Liquid feed (maintained below the level of tubes) is pumped into the tubes with a positive velocity. Steam introduced through the inlet pipes (calandria) moves upwards. As the steam loses its heat, it results in the formation of condensed gases which are removed as condensate from the outlet.

When the liquid moves up within the tubes, it gets heated due to the heat energy acquired from the steam. This leads to rapid boiling of the liquid, which along with vapour moves upwards with much higher velocity. This mixture of liquid and vapour then strikes the curved deflector present within the vapour head. The vapour moves upwards and gets removed from the equipment via the vapour outlet. Separated liquid from the mixture moves down the return pipe and is recirculated by the pump. Finally, concentrated product is collected from the outlet.

Advantages of Forced Circulation Evaporator

- It has high heat transfer coefficient (HTC) as it involves pumping of the liquid at high velocity.

- As positive circulation is maintained, it can be used for viscous preparations.

- Salting and scaling do not occur.

- Suitable for thermolabile substances.

Examples: Meat and liver extracts, insulin etc.

Disadvantages of Forced Circulation Evaporator

- Expensive.

- Requires power for pumping the liquid.

- Hold-up time of liquid is high.

Applications of Forced Circulation Evaporator

- Useful for concentrating liver and insulin extracts.

- Crystalline substances can be obtained by evaporation.

- It is useful to concentrate corrosive liquids and alcoholic solutions.

- It is useful in case of foaming solutions, as the liquids do not boil.

- It is used to concentrate viscous solutions due to improved heat transfer.

Examples: Gelatin solution, syrups, tomato paste, mango pulp etc.