Falling film Evaporator is a type of long tube evaporator, in which high velocity feed enters from the top of the evaporator and flows down the walls, hence the apparatus is named as Falling film evaporator.

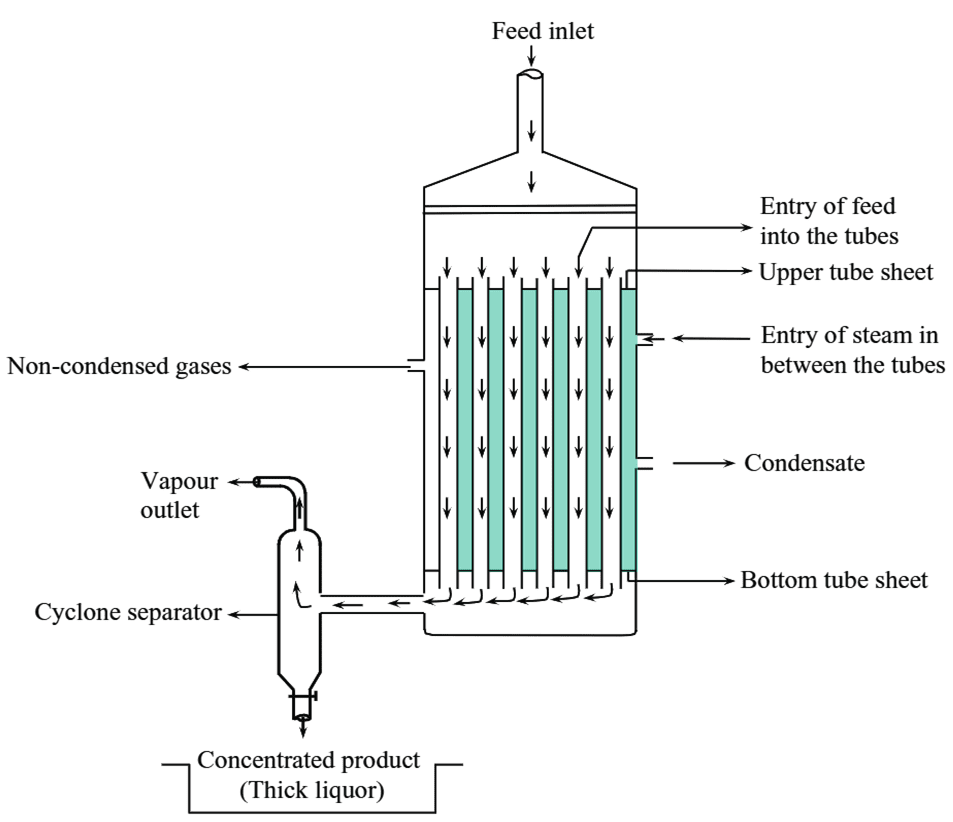

Figure 1: Falling Film Evaporator.

Working Principle of Falling Film Evaporator

As the feed moves downwards, its temperature increases and it forms vapours. These vapours form small bubbles which then aggregate to form large bubbles and travel downwards. This mixture of liquid and vapour gets separated at the bottom. The separated liquid gets concentrated during falling and is collected as product from the bottom.

Construction of Falling Film Evaporator

In falling film evaporator (see Figure 1), tubes of 8 cm diameter are held by tube sheets. The design is exactly similar to climbing (rising) film evaporator but the only difference is that the apparatus is inverted and lacks a curved deflector. Feed inlet is present at the top whereas steam inlet is present along the sides. Two outlets for condensed and non-condensed gases are also present. A cyclone separator is attached to the evaporator.

Working of Falling Film Evaporator

Feed enters from the top and flows down the inner walls of the vertical tubes. Steam is supplied in between the tubes which boils the liquid present within the tubes. The boiling liquid vapourizes and forms small bubbles. These bubbles fuse and travel down the tubes. Towards the bottom of the tubes, vapour and liquid get separated in the cyclone separator. Vapours get removed from the vapour outlet, while the liquid gets concentrated and is obtained as a thick liquor.

Advantages of Falling Film Evaporator

- Absence of hydrostatic (vapour) head, prevents any increase in the boiling point of the liquid.

- Hold-up time of liquid is less.

- Short contact (residence) time i.e., around 30 seconds.

- No obstruction in the flow of liquids.

- Steam temperature difference can also be maintained up to 20ºC, thereby decreasing scaling and facilitating the cleaning of the equipment.

- Maintenance is easy.

Disadvantages of Falling Film Evaporator

- As it is associated with non-uniform distribution of feed, it is not suitable for solid feeds and suspensions.

- Not suitable for salting or scaling liquids.

- Recirculation may be required at times.

- Dry spots may form at the bottom of the tubes, as the rate of evaporation is high.

Applications of Falling Film Evaporator

- Used for concentrating thermolabile materials (like fruit juices) and critically heat sensitive liquors.

- Used in sugar industry.

- Used in concentrating urea and phosphoric acid in fertilizer industries.

- Used to concentrate black liquor in paper industries.

- Used to concentrate the extracts of tea, coffee and yeast.

- Used in the manufacture of gelatin.

- Used for handling foaming or frothing liquors.

- Used to separate volatile and non-volatile components from low viscosity feed.

- Used for handling highly corrosive and acidic feeds by using impervious tubes of graphite and rubber lining in the vapour head.