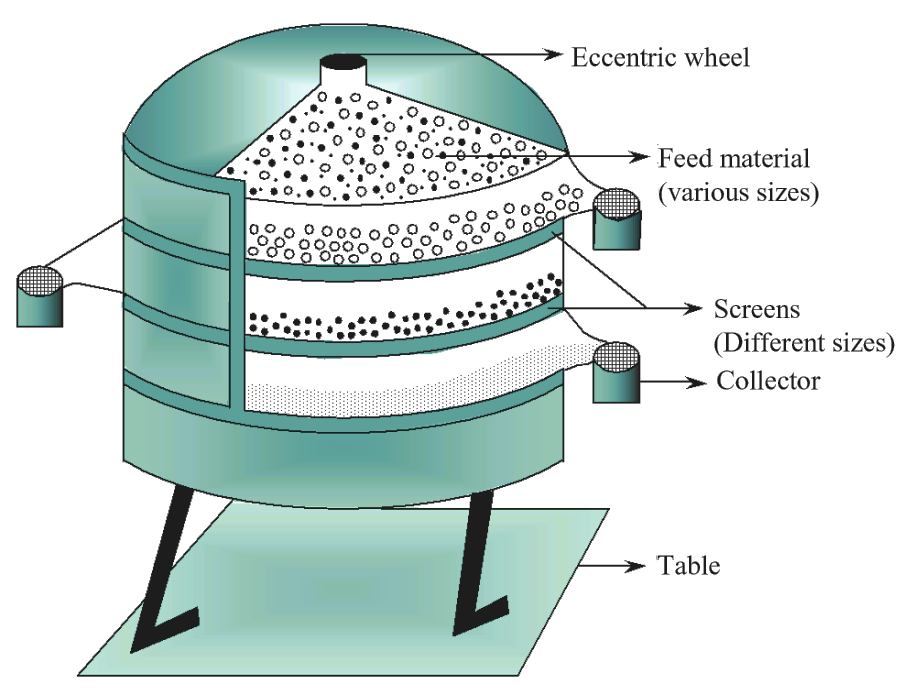

Figure 1: Vibrating Screen (or Vibrating Screen).

Working Principle of Vibrating Screen

Vibrating Screen (or Gyratory Screen) works on the principle of gyratory motion. The sieve placed on the rubber mounting rotates in a circular manner on a fixed axis by means of an eccentric flywheel. This gyratory movement results in the upward and downward movement of feed due to which it is slightly inclined from vertical axis and the direction of inclination changes continuously in clockwise direction. Rotation of unbalanced top weight screens causes vibration in horizontal plane while rotation of lower weight causes inclination and vibrations in vertical plane.

Construction of Vibrating Screen

It is a box like machine which is either round or square in shape. It consists of a series of screens nested atop one another in a vertical sack with downward-decreasing mesh opening sizes. Gyratory screens often contain ball trays and ultrasonic devices fitted below the screens. The screens are supported on a table which is mounted on springs on a base. Beneath the table, a motor with double shaft extension is present.

Working of Vibrating Screen

The feed material to be size separated is placed on the topmost sieve and is covered in order to avoid loss of material during gyration. Sieves are stacked one above the other in such a way that the most coarse sieve is placed on the top followed by the sieves with decreasing mesh size. In other words, they are arranged in increasing order of sieve number and decreasing aperture size. Gyratory screen is then shaken vigorously in oscillatory manner which is achieved by eccentrics or counterweights. Additional auxiliary vibration is caused by balls (bouncing) colliding against the lower surface of screen. Feed rolls over the screen and falls under the influence of gravity and directional shifts. The circular or near circular motion of the particles causes the undersized feed particles to pass through the screen which is collected finally into the receiving pan.

Advantages of Vibrating Screen

- Simple and easy to handle.

- Low maintenance and power consumption.

- Superior accurate separation and high processing rate/area of screen.

Disadvantages of Vibrating Screen

- As the particles collide with one another, it may lead to attrition and the particles may be further size reduced. This may give false results.

- If the powder to be analyzed is moist then the sieve apertures get clogged thereby resulting in inefficient sieving.