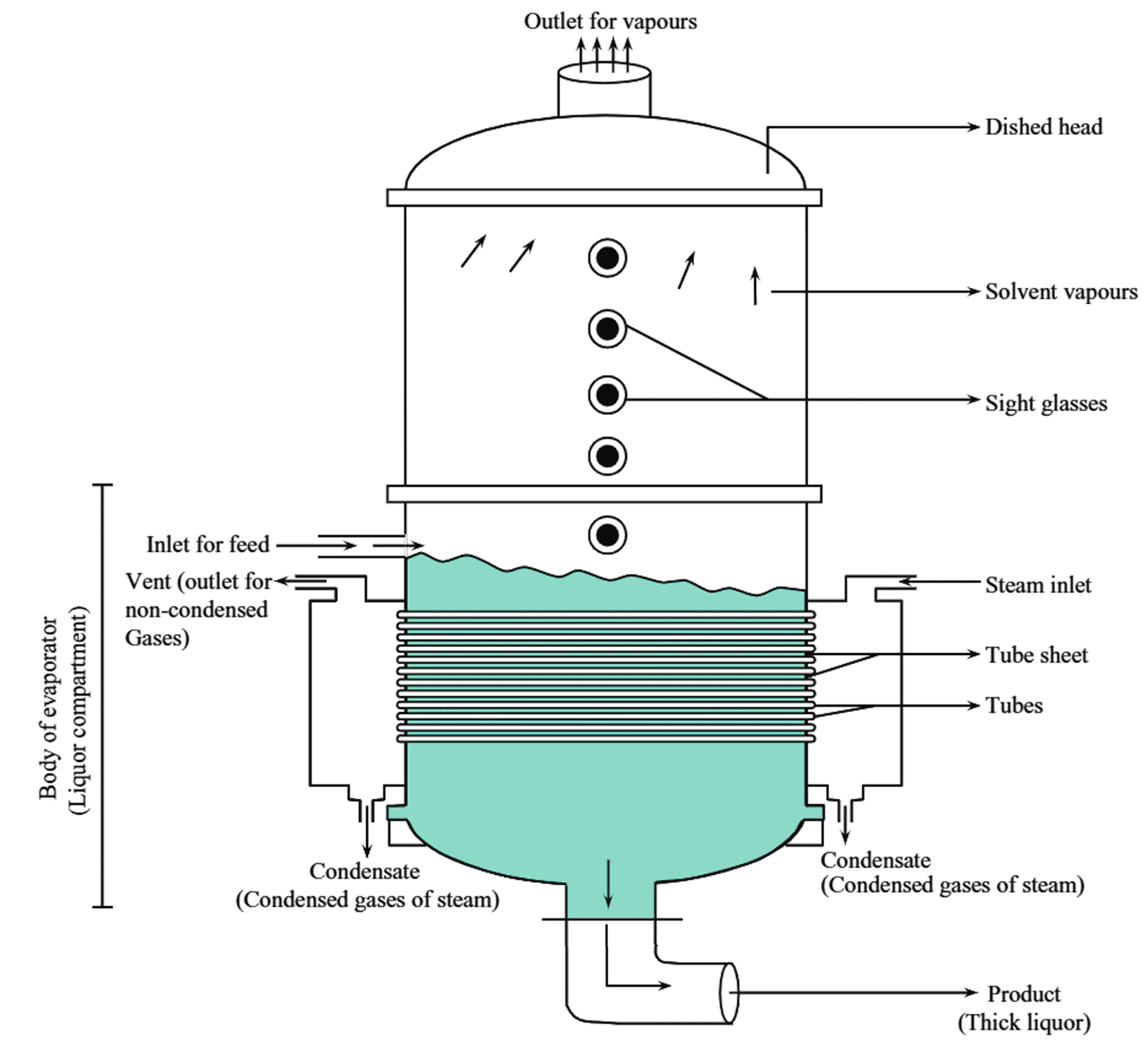

Figure 1: Horizontal Tube Evaporator.

Working Principle of Horizontal Tube Evaporator

The main principle involved in Horizontal Tube Evaporator is the natural circulation (or recirculation) of steam as steam is present inside the tubes. Boiling of the feed occurs which leads to vaporization of the solvent. It is also known as Wellner Jelinek type evaporator.

Construction of Horizontal Tube Evaporator

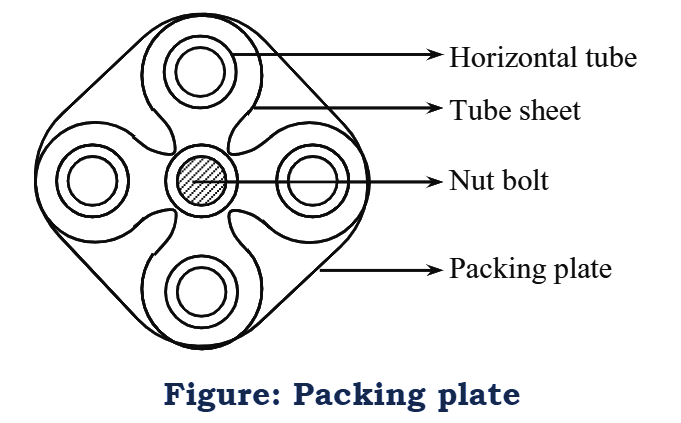

Horizontal Tube Evaporator is made of steel or cast iron. It is cylindrical shaped and is closed at the top and bottom with dished heads. The total height of this evaporator ranges from 8-12 feet and the diameter varies from 36 inches to 12 feet (or 144 inches). The lower part (or body) of this evaporator is known as liquor compartment. At the bottom of the horizontal tube evaporator inlets for feed and steam are present on either side, whereas outlets are present for non-condensed gases and condensate. Brackets are present at the bottom of this equipment to provide it support as well as to de-assemble the equipment. Horizontal bundles of folded tubes are fastened to the tube sheets in the liquor compartment. The outer diameter of the tubes varies from 0.87 inches to 1.25 inches. The width of the tubes is nearly half the width of the body of evaporator. These tubes are cut long enough, hence they project I inch from either sides of the tube sheet. Holes are bored within the tube sheet so as to insert the tubes. The holes are cut in slight bigger size when compared to the outer diameter of the tube. Conical rubber gaskets are fitted over the tubes, so that the tubes gets affixed into the tube sheet. These folded tubes are tightly secured by packing plate. Each packing plate includes a set of 4 folded tubes.

The packing plate is in tum held with these tubes by a nut bolt. This nut bolt is present at the center of the four packed tubes. Packing plate also ensures easy removal of tube sets. At the top of the evaporator, an outlet for vapour removal is present. At the bottom of the evaporator exactly at the center, an outlet for collection of product (as thick liquor) is present. Sight glasses are present on the evaporator to view the process occurring within the equipment.

Working of Horizontal Tube Evaporator

Through the feed inlet pipe, feed enters into the liquor (or steam) compartment. The level of the feed is slightly taken above the level of the horizontal bundle of tubes. Steam is passed through the steam inlet pipe into the evaporator. The bundle of horizontal tubes present within the evaporator receives heat (from the steam) and transfers it to the liquid feed present above it. The molecules present in the feed attains kinetic energy. The kinetic energy causes the molecules to overcome the liquid phase intermolecular forces, hence vaporization of volatile component of the feed occurs. These vapours are allowed to escape from the top of the evaporator. The non-condensed gases present within the evaporator escape through the vent. (An outlet for non-condensed gases). The outlet for non-condensed gases is present exactly opposite to the stem inlet. The steam which has entered the evaporator loses its kinetic energy after sometime and undergoes condensation. The condensed gases of steam (i.e., condensate) are collected from the outlets present at the bottom of liquor compartment. This unit operation of evaporation is carried out in the horizontal tube evaporator until a thick concentrated liquid is obtained. This concentrated liquid (product) is collected from the bottom of the evaporator through the outlet pipe.

Advantages of Horizontal Tube Evaporator

- Consumption time of evaporation process is less when compared to evaporating pan.

- Cost of heating surface per square meters is very less in horizontal tube evaporator.

- The bundle of tubes can be easily removed.

- Suitable for concentrating thermolabile substances.

- Suitable for substances which tend to foam. This is because the horizontal tube evaporator has a greater capacity to separate vapours from the feed.

Disadvantages of Horizontal Tube Evaporator

- Liquid circulation is poor.

- It is not suitable for viscous substances.

- High in cost.

Applications of Horizontal Tube Evaporator

- The equipment of horizontal tube evaporator is carried for liquids that do not form scales within it during the evaporation process.

- Non-viscous solutions can be concentrated.

- Thermolabile materials are handled.

- By using this evaporator, cascara extract can be concentrated.