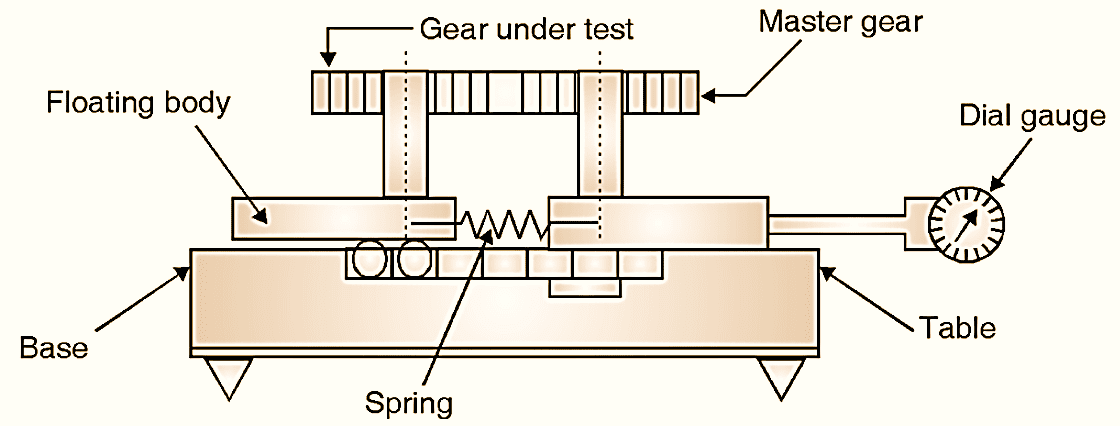

Figure 1: Parkinson’s Gear Tester.

Instead of measuring individual errors in gears, composite errors are checked. The composite error indicates the combination of errors in a gear. In Parkinson’s Gear Tester, the gear to be tested is rolled in mesh with a master gear and the errors will be indicated by dial gauge or recording unit.

Construction and Working of Parkinson’s Gear Tester

One fixed spindle and other movable spindle is mounted on a flat base. The movable spindle moves along with base by rolling action on the main base plate as shown in Fig. 1.

A master gear is mounted on the fixed spindle whereas, a gear to be tested is to be mounted on a movable spindle. The dial gauge is set to note the errors as shown in Fig. 1 whose pointer touches the floating body.

Procedure for Measurement using Parkinson’s Gear Tester

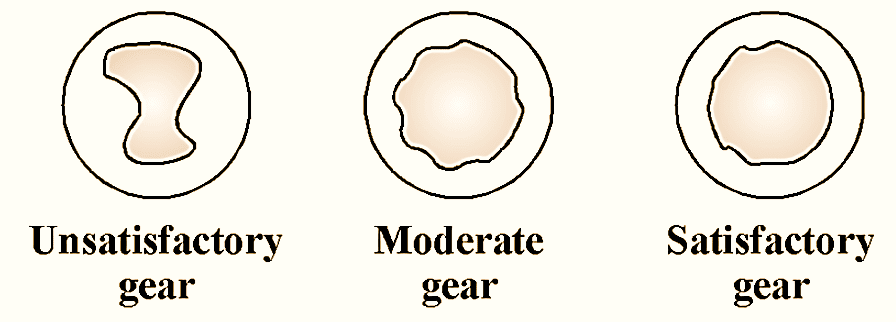

Figure 2: Profiles of gears.

When master gear is rotated slowly, a gear to be tested will also get rotation movement because of their meshing. Errors in the manufactured gear cause the gear to move away from the center line of spindle. When gear (on test) moves, the floating body, also move, by the same distance. Because of displacement of floating body, dial gauge gives displacement. The variations in the readings can be observed and plotted in the graphical format. Fig. 2 shows a typical graphs for unsatisfactory, moderate and satisfactory gears.

Limitations of Parkinson’s Gear Tester

- Maximum 300 mm diameter gears can be tested.

- The floating body is very sensitive and hence readings are to be taken very carefully.

- Accuracy upto 1 µm can be possible while measurement

- Only composite errors in the gears can be checked, not individual one.

- Measurement depends upon the master gear.