In this topic, you study Capacitor Start Induction Motor – Theory, Construction, Diagram, Working, & Torque Speed Characteristic.

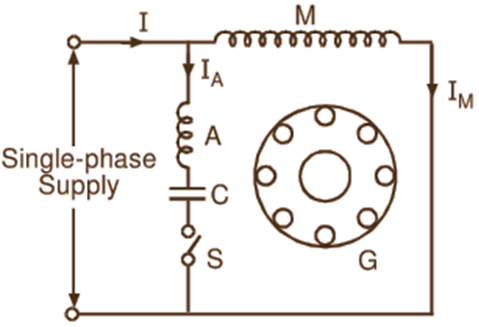

In Capacitor Start Induction Motor, the auxiliary winding (A) in series with a capacitor (C) is in the circuit only during the starting period and then disconnected with the help of a centrifugally operated starting switch (S) after the motor reaches 75 to 80 % of the synchronous speed. This type of motor is shown schematically in Fig. 1 (a) and Fig. 1 (b) shows the phasor diagram.

(a)

(b)

Fig. 1 : (a) Schematic representation of a capacitor-start, single-phase induction motor, (b) Phasor diagram

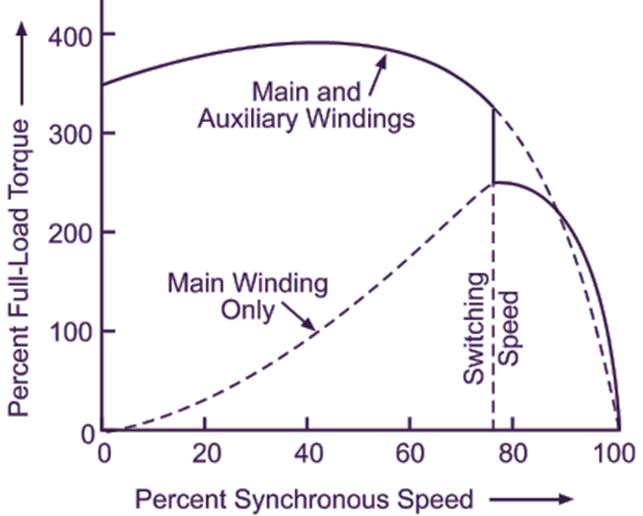

Torque Speed Characteristic of Capacitor Start Motor

Torque speed characteristic of this type of motor is shown in Fig. 2. The starting torque of this type of motor is generally of the order of 350 to 400 % of the full-load torque. Thus, high starting torque is the outstanding feature of this motor.

Fig. 2: Typical torque-speed characteristic of a capacitor-start motor.

Characteristic of Capacitor Start Motor

The characteristic features of single phase capacitor start induction motors are as follows.

- Capacitor start motors can be used for dual voltage ratings.

- They can also be used in applications where starting orque requirement is high.

- They have two windings i.e., start and run winding. When motor is started both the windings are energized but when motor attains 75% of full load speed, start winding and capacitor are disconnected from the circuit by a centrifugal switch.

How can the direction of rotation of capacitor start motor be reversed?

The direction of rotation of capacitor start motor can be reversed by interchanging the connections of starting winding without disturbing the capacitor connections. The direction of motor can be reversed oniy before the starting operation of the motor i.e., when the motor is at rest and the centrifugally operated starting switch is in closed position. Because once the motor comes in normal operating condition it will be running as single phase induction motor and at this moment the reversal of motor is attempted, then there will be no effect on the direction of rotation as centrifugally operated starting switch will be in open position and the developing torque will be in the direction of rotation.

Applications of Capacitor Start Motor

- Due to high starting torque, capacitor start induction motors are used for high inertia loads and also where regular starts are needed.

- Capacitor start motor are also used in applications like pumps, compressors, refrigerators, air-conditioners, conveyors, machine tools etc.