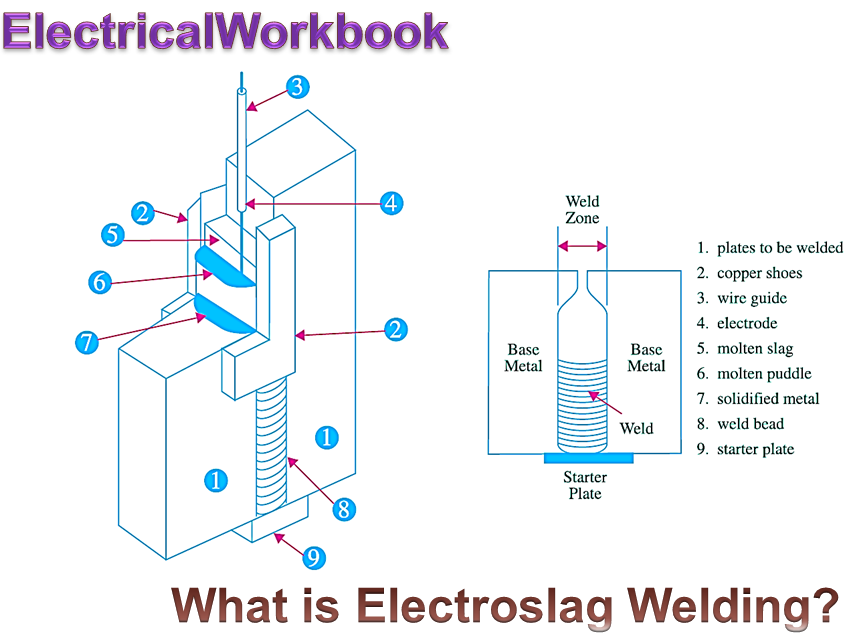

Electroslag welding is used to join two thick metal plates without edge preparation. The plates to be welded are held in vertical position keeping some gap between edges. Continue reading What is Electroslag Welding? Process, Diagram, Advantages & Disadvantages