Chillers are used for cooling the secondary refrigerants. For example: Water. Chiller is said to be a special refrigeration device, Which cools water or any other fluid. This chilled water or fluid is circulated to a remote location for cooling purpose. Chillers are similar to evaporators, except that, evaporators are directly used for cooling a room or space, whereas, chillers are used to cool the water, so that, this chilled water can be circulated through cooling coils to cool a remote space (i a type of indirect cooling). Thus, evaporators directly cool the application, whereas, chillers indirectly cool the application. Refrigeration capacity of a chiller ranges from 3 TOR to 1000 TOR

Types of Chiller

Chillers are classified as,

According to construction:

- Dry expansion or DX chiller.

- Flooded chiller.

According to Refrigeration cycle used:

- Chiller working on Vapour compression cycle.

- Chiller working on Vapour absorption cycle.

What is DX Chiller?

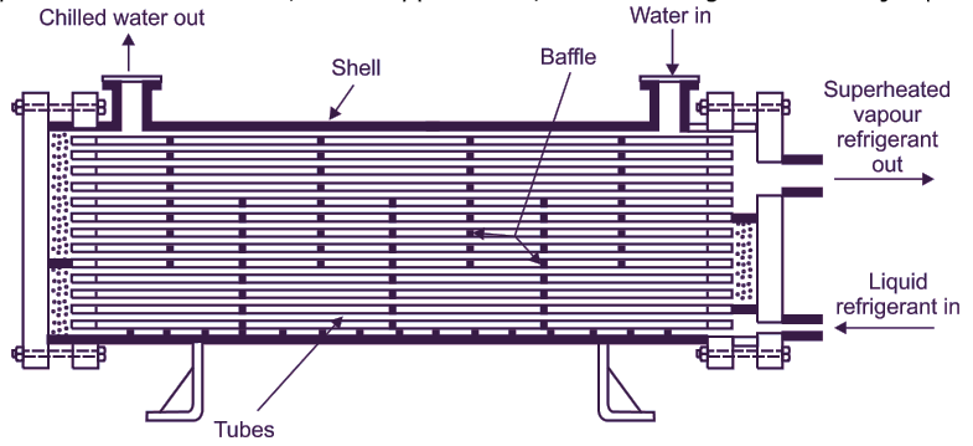

Dry expansion type chiller is also called as ‘DX chiller’ The water or liquid to be cooled is in the shell, while the refrigerant is in the tubes. The working of DX chiller is similar to the dry expansion evaporator. It is ensured that, superheated vapour refrigerant comes out of chiller. Baffles are provided in the water passage inside the shell of chiller, to regulate the velocity of water passing over the surface of tubes, such that, the liquid refrigerant flowing through tubes have enough time to absorb heat from the water. This leads to increase in heat transfer efficiency, which ensures superheated vapour refrigerant leaving the chiller. Also, the water gets chilled in minimum time. In some applications, where the quantity of water to be handled is more, wider baffle spacings are provided. This provision restricts the water velocity from becoming too high. Shell side of the chiller is not accessible. Therefore, it is not possible to clean the water passage. So good quality strainers or filters are provided for cleaning the impure water at the inlet of water line connected to the chiller. This type of chiller is not used, in the applications, where fouling can be a major problem.

Fig. 1: Dry expansion type chillers

What is Flooded Chiller?

In case of dry expansion type chillers, problem of fouling is found across the water surfaces, which decreases the heat transfer capacity. In flooded chillers, water or brine to be cooled is circulated through the tubes and the refrigerant is in the shell side. This is opposite to that of dry expansion type chillers. Due to this arrangement, it is possible to brush and clean the water tubes. Therefore, flooded chiller is more suitable and preferable than a DX chiller, in applications like textile mills air conditioning, industrial refrigeration etc.

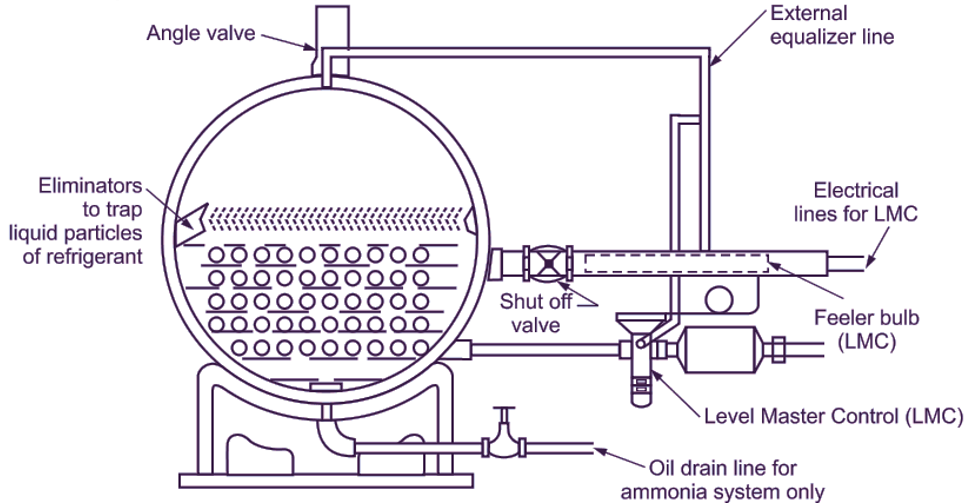

Fig. 2: Flooded chiller

The liquid refrigerant level in the shell is maintained, such that, it completely submerges the water tube bundle. Thus, the evaporator surface is always wetted by the refrigerant, which improves the heat transfer capacity of the flooded chiller. There will be intimate contact between the liquid refrigerant and the evaporator surface, regardless of load and the resultant refrigerant velocity. Hence, like DX chillers, it is not necessary to rely on refrigerant velocity for the wetting action of the evaporator surface in flooded chillers. Also, the agitation (i.e. method of mixing turbulently or stirring up) due to boiling and the resultant upward movement of the vapour refrigerant through the liquid refrigerant improves the heat transfer efficiency. Thus, the flooded chiller With integrally finned tubes is smaller in size and lesser in weight as compared to the DX chiller of same capacity. Due to the agitation caused by the boiling of the liquid refrigerant, the liquid refrigerant behaving like high velocity jet gets pulled into the suction line along with the vapour refrigerant. To trap such escaping liquid and to prevent it from entering the suction line and the compressor, an ‘accumulator or ‘surge drum’ is provided at the suction outlet of the chiller. The accumulator is much bigger in size and cross-sectional area as compared to the suction line.

Hence, velocity of vapour refrigerant will be very low and the liquid particles drop down to the bottom of the accumulator and only the vapour refrigerant passes to the suction line. Modern chillers have an empty space provided at the top half of the chiller shell, thereby eliminating the necessity of a separate accumulator. Because of the large volume and cross-sectional area of this space, the velocity of vapour refrigerant is very low. Therefore, it cannot pull the heavier liquid refrigerant particles, along with it. Only the lower half of the chiller has the tube bundle. As an added precaution, an eliminator assembly is fixed just above the normal working liquid level in the chiller, to trap liquid particles of refrigerant.

Applications of Flooded Chillers

- Textile mills air conditioning,

- Industrial refrigeration

Chiller Working on Vapour Compression Cycle

Chiller working on vapour compression cycle consists of a compressor, an air cooled condenser, an expansion valve and a cooler (similar to an evaporator). Refrigerant absorbs the heat from the water, which is to be chilled. If condenser is air cooled, then atmospheric air comes in surface contact with the refrigerant. The refrigerant gives away the absorbed heat to the atmospheric air and gets cooled down. If condenser is water cooled, then cooling water coming from cooling tower is circulated inside the condenser. This cooling water absorbs the heat from refrigerant and gets heated. It is then sent back to cooling tower, where it rejects the heat and becomes cooled again. Th s cooling water is again sent to the condenser for repeating the process of cooling with condensation. Thus, recirculation of coo ing water from cooling tower to condenser and condenser to cooling tower is done. If centrifugal compressors are used, then the chiller is called as centrifugal chiller.

Chiller Workin on Vapour Absorption Cycle

For a chiller working on vapour absorption cycle, the compressor is replaced by absorber-generator combination. Heating in generator can be done by using electrical heaters or steam or hot water. Absorption type chillers are ab e to produce refrigeration effect, up to 500 TORs. In air conditioned buildings, two or three chillers are used with one stand by unit.