A double cage rotor motor gives excellent starting and running characteristics than a deep-bar cage rotor motor. It also provides a high starting torque with a low starting current. Therefore it is also known as low-starting current, high starting torque, low slip-motor. The rotor is well designed in order to have high resistance rotor circuit during starting and low resistance rotor circuit when operating at running conditions. In case of double squirrel cage motor, the starting torque ranges between 200 to 250 percent of full-load torque whereas starting current ranges in between 400 to 600 percent of full-load current.

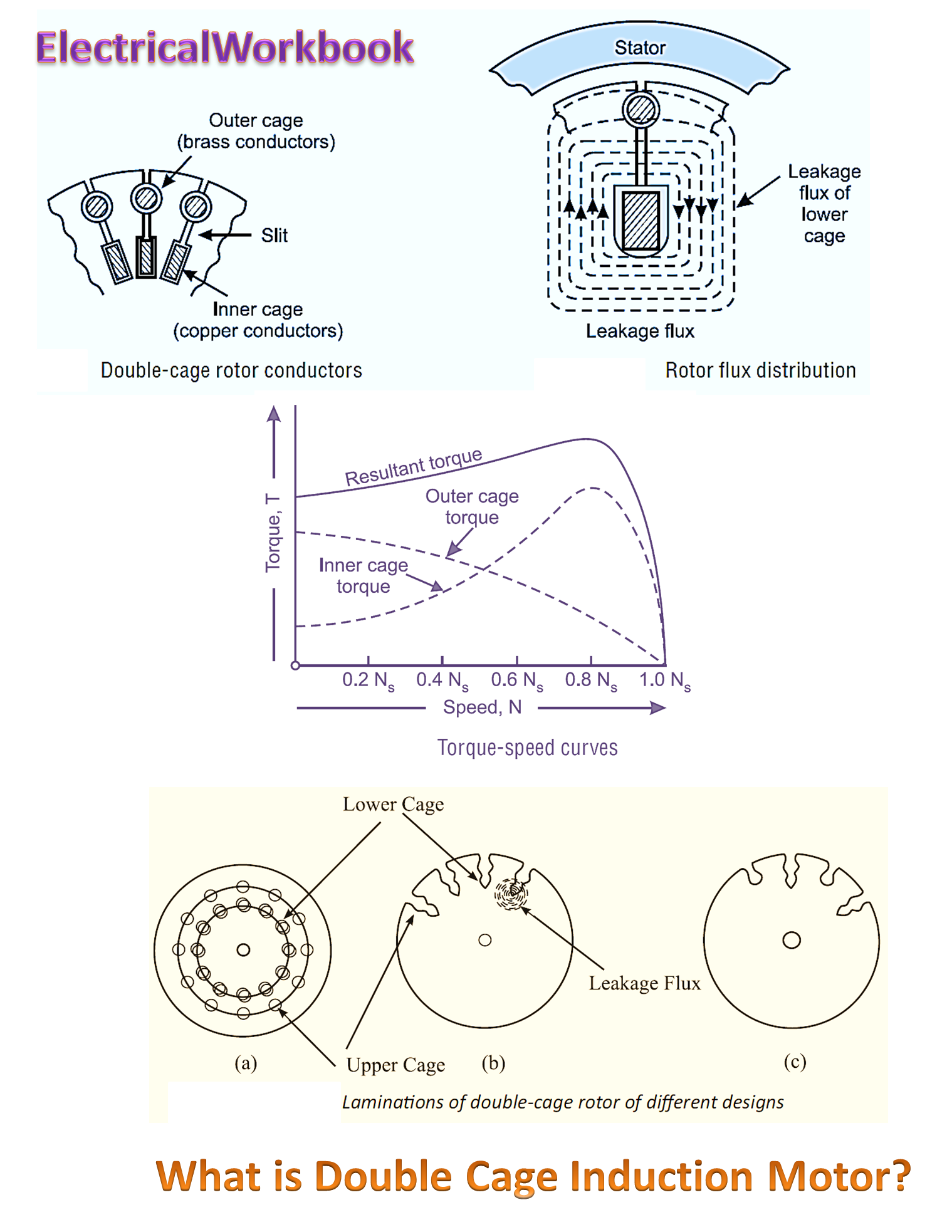

Double Cage squirrel cage induction motor with a specialty of different types of rotor having not only one cage but two different independent cages of different resistances and cross-sectional areas (Fig. 1).

Fig. 1: Double Cage Induction Motor.

Construction of Double Cage Induction Motor

The squirrel cage motor has two main parts the stationary and rotory parts. The stationary parts are those which remain stationary during the operation of motor viz, body or yoke, side covers, bed sheet, flench covers, terminal box etc. The rotory parts are those which rotates during the working of motor viz, rotor, fan, shaft, bearings, etc. The stator of the motor has slots and in them a three phase winding whether in star or in delta is done according to the designing of the motor winding.

The rotor of this type of motor is specially designed. There are two distinct rotor windings say two different cages (See Fig. 1). The stampings are respectively designed having provision of two separate windings, one having rotor bars close to the surface and other having some distance i.e., deep into the rotor stampings. Both the cages are short circuited independently at both the ends, i.e., in the same fashion as that of single squirrel cage rotor winding.

The resistances of both inner cage and outer cage are different. The outer cage have high resistance compared to inner cage. It is generally made of iron or brass bars. Since this cage is near the periphery, the reactance of the windings due to magnetic leakage will be less. The inner cage is made of low resistance material wire such as copper deeply embedded, as a result more flux as compared to upper cage will be linking and resulting more reactance. The resistance of both cages (apart from the selection of material) is made different by choosing different cross sectional area of the conductors. The outer cage is made of less cross sectional area resulting more resistance. The inner cage is made of larger cross sectional area resulting less resistance.

Working of Double Cage Induction Motor

When the three phase supply is given to the stator a rotating magnetic field is produced. The flux links the rotor conductors and according to the Faradays Laws of electromagnetic induction an e.m.f. is induced in the rotor bars. Initially, when the rotor is stand-still, the magnetic flux linking the bars, will have the same frequency as that of supply voltage. The flux links both the windings i.e., cages inducing an emf. As both the squirrel cages are short circuited, by the independent end rings, the circulating current starts flowing. The quantity of current will be different in both the cages. The inner cage have maximum reactance resulting more impedance and so less current in this cage bars. The upper cage being on top results less reactance and hence the impedance, as compared to inner cage will be considerability less as a result more current will flow through the upper cage. Thus the starting torque produced by the outer cage will be more (the outer cage has more resistance). There will be less current flowing through innercage (which has less resistance) thus the torque produced will also be less.

As the motor speeds up, the slip speed comes into existence and this the flux linking the rotor conductors reduces its speed and hence frequency. The reactance of the inner cage becomes less resulting less impedance and more current. The outercage has more resistance as compared to inner cage causes more impedance and as a result less current and less torque.

Thus in starting the motor is started mainly because of outer cage (having more resistance) and in running condition the torque is produced by the inner cage (having less resistance). Thus we get high starting torque and less starting current with high running efficiency.

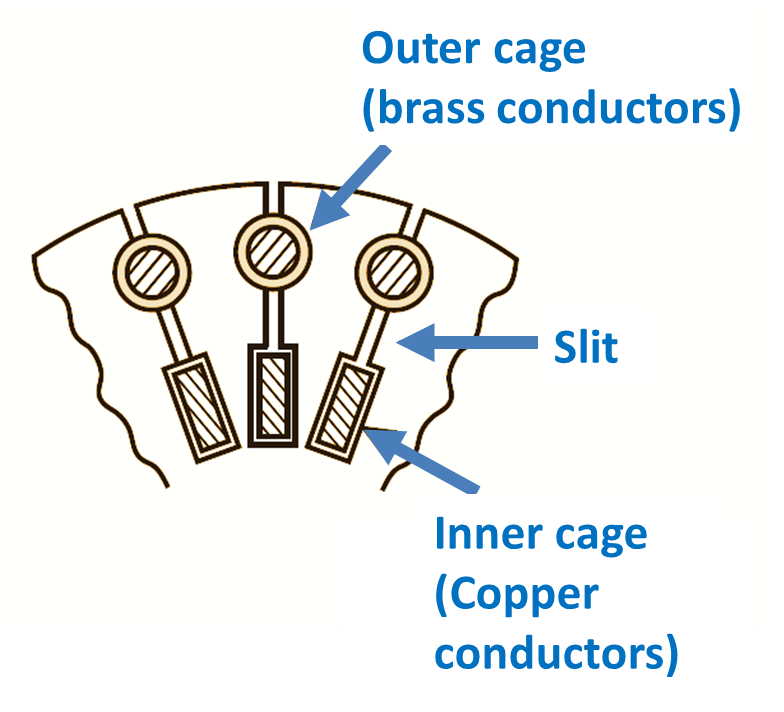

Torque-speed characteristics of Double Cage Induction Motor

The torque-speed characteristics of the outer cage, inner cage, and double cage induction motor (Resultant torque) are shown in Fig. 2 separately.

Fig. 2: Torque-speed characteristics.

Advantages of Double Squirrel Cage Induction Motor

- It reduces the starting current.

- It increases the starting torque.

Disadvantages of Double Squirrel Cage Induction Motor

- Maxiimun torque is less.

- Power factor is low.

- Efficiency is less.

- Rotor copper losses are high.

- Cost is high.