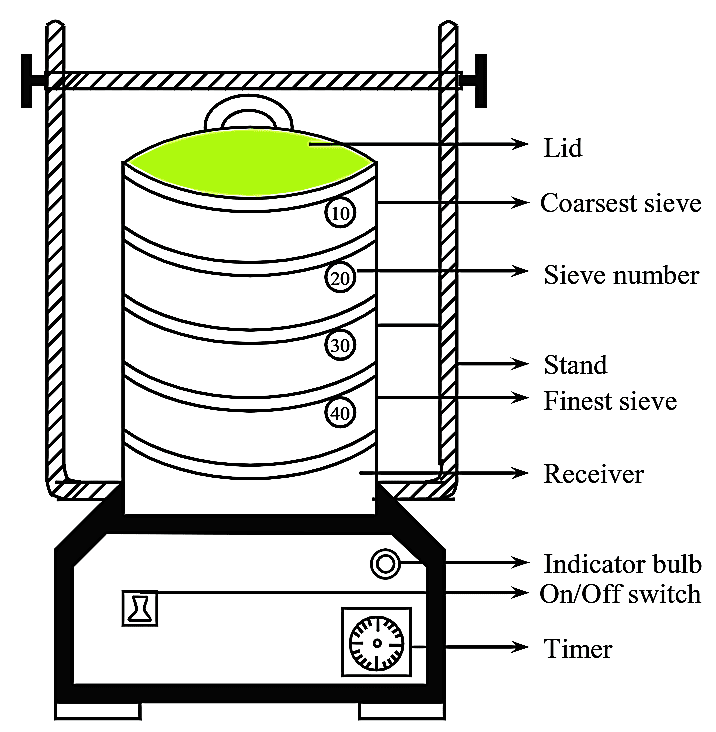

Figure 1: Sieve Shaker Machine.

Working Principle of Sieve Shaker Machine

In Sieve Shaker Machine, a set of standard screens as per USP and IP specifications are stacked on a mechanical shaker device. The entire set-up is then subjected to different modes of agitation (vibrating, oscillatory or reciprocating or to and fro and gyratory), so as to increase the rate of size separation process.

Construction and Working of Sieve Shaker Machine

Sieves are stacked one above the other in such a way that the most coarse sieve is placed on the top, followed by sieves with decreasing aperture sizes (see Figure 1). In other words, they are arranged in increasing order of sieve number and decreasing aperture size. A receiving pan is placed at the bottom of the screen to collect the last fraction of powder. A specified sample to be size separated is placed on the topmost sieve and is covered to avoid loss of material during agitation. The entire sieve set is placed on a mechanical sieve shaker. The setup is vigorously agitated for a specified period of time. The fraction of material collected on each screen is weighed. The weight of each fraction is termed as weight fraction of the total sample.

Advantages of Sieve Shaker Machine

- Simple and easy to handle

- Low cost (cheaper).

Disadvantages of Sieve Shaker Machine

- Particles up to 50 μm size can be obtained.

- If the powder to be analyzed is moist then the sieve apertures get clogged due to which the sieving efficiency decreases.

- As the particles collide with one another, it may lead to attrition and the particles may be further size reduced. This may give false results.

Applications of Sieve Shaker Machine

Sieve shaker apparatus is employed for sieve analysis to determine the efficiency of the size reduction equipment.

Modifications of Sieve Shaker Machine

Mechanical sieve shaker machine can be replaced by an electromagnetic sieve shaker and sonic sifter (sonic oscillations are used). These give accurate results. The machine is modified in such a way that a mechanical pulse action is created, so as to avoid any blinding or agglomeration.