Capillary tube is used as an expansion valve in small capacity hermetically sealed refrigeration units such as domestic refrigerators, water coolers, room air conditioners and freezers. Capillary tube is a tube of small internal diameter and of varying length, which depends upon the application. It is made up of either copper or steel.

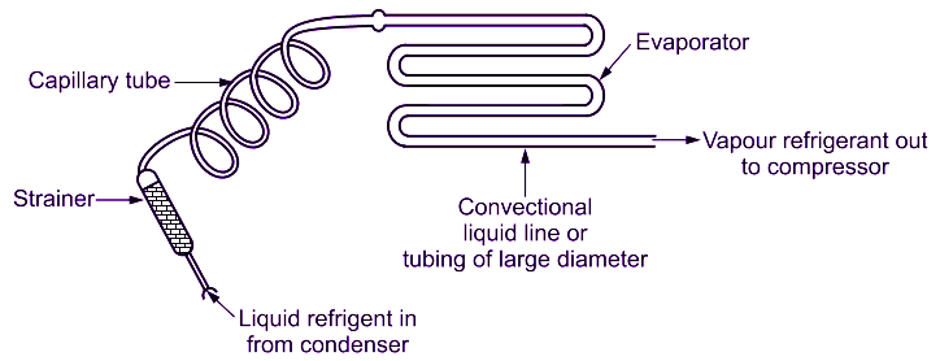

Fig. 1: Capillary tube

Working Principle of Capillary Tube

Capillary tube works as an expansion device in refrigeration system. Therefore, during flow of refrigerant through capillary tube, high pressure, low-temperature liquid refrigerant should become ow pressure, low temperature liquid refrigerant. In refrigeration system, high pressure is condenser pressure, whereas, low pressure is evaporator pressure. Thus, the function of capillary tube is “to create a pressure drop by reducing the pressure of liquid refrigerant from condenser pressure to evaporator pressure”. The amount or extent of pressure drop through capillary tube depends upon the internal diameter and length of tube. When the high pressure, low temperature liquid refrigerant leaving the condenser coils is made to flow through capillary tube, frictional resistance occurs between the liquid refrigerant and inner surface of small diameter capillary tube. Due to this frictional resistance, pressure of liquid refrigerant drops from condenser pressure to evaporator pressure.

Construction of Capillary Tube

The inside diameter of capillary tube is generally about 0.5 mm to 2.25 mm and the length varies from 0.5 m to 5 m. A fine mesh screen i.e. strainer (filter) is provided at the inlet of capillary tube in order to protect it from contaminants. In its operation, the liquid refrigerant from the condenser enters the capillary tube. Due to the frictional resistance offered by a small flow area (i.e. due to small diameter) of capillary tube, the pressure drops. Greater pressure difference is needed between the condenser and evaporator (i.e. high Side and ow side), which depends upon the mass flow rate of refrigerant and desired capacity of application. Since the frictional resistance is directly proportional to the length and inversely proportional to the diameter, therefore longer the capillary tube and smaller the inside diameter of capillary tube, greater is the pressure drop created in the refrigerant flow. Thus, the capillary tube maintains the required pressure difference between the condenser and the evaporator by restricting and metering (i.e. measuring) the flow of refrigerant. The capillary tube can be described as a fixed length, small bore tubing installed between the condenser (high pressure side) and evaporator (low pressure side) in place of conventional liquid line of a refrigerating system as shown in Fig. 1. The diameter and length of the capillary tube once selected for a given set of conditions and load cannot operate efficiently at other conditions. Since the tube cannot close or shut off when the compressor stops, the liquid continues to flow through it from the condenser to the evaporator until the pressure equalises between high and low sides.

Applications of Capillary Tube

- Domestic refrigerator.

- Air conditioners.

Advantages of Capillary Tube

Low cost: The cost of capillary tube is less than other expansion devices.

Low starting torque required: When the compressor stops, the refrigerant continues to flow into the evaporator and equalizes the pressure between the high side and low side of the system. This considerably decreases the starting load on the compressor. Thus, a low starting torque motor (i.e. low cost motor) can be used to drive the compressor, which is a great economical advantage.

No need of Receiver: Since the refrigerant charge in a capillary tube system is critical, therefore, no receiver is necessary.

Long life: Rough handing does not affect the working of capillary tube. Hence, life of capillary tube is more.

Disadvantages of Capillary Tube

- Not suitable for refrigeration systems subjected to high fluctuating loads.

- Contaminants in the refrigerant such as moisture and dirt may choke the tube and stop the flow of refrigerant.

Control of Flow of Refrigerant by Capillary Tube

As the load on the evaporator increases, the liquid refrigerant will be vapourized in the evaporator and condensed in the condenser at a rate momentarily higher than that, at which, the capillary tube is supplying the liquid refrigerant to the evaporator. As a result, excess liquid refrigerant will accumulate at the end of the condenser. Now, with the condenser partially filled with liquid refrigerant, the condenser pressure will be increased. At the same time, the liquid refrigerant in the end portion of the condenser coil will be subjected to a greater degree of subcooling, so that, there will be less vapour refrigerant (flash gas) formed in the capillary tube. Both of these conditions tend to increase the flow capacity with the increased system load. However, as the load on the system decreases, the condensing pressure and the degree of subcooling decreases, so that, the flow capacity of the tube decreases.