Data Acquisition System is a group of various devices that are combined in an orderly fashion to perform necessary operations on relevant data. Usually a data acquisition system is an assembly of sensors/transducers, signal conditioners, data conversion, data handling, data processing units, multiplexing circuits, data transmission, data storage and data display systems.

Data Acquisition System Block Diagram

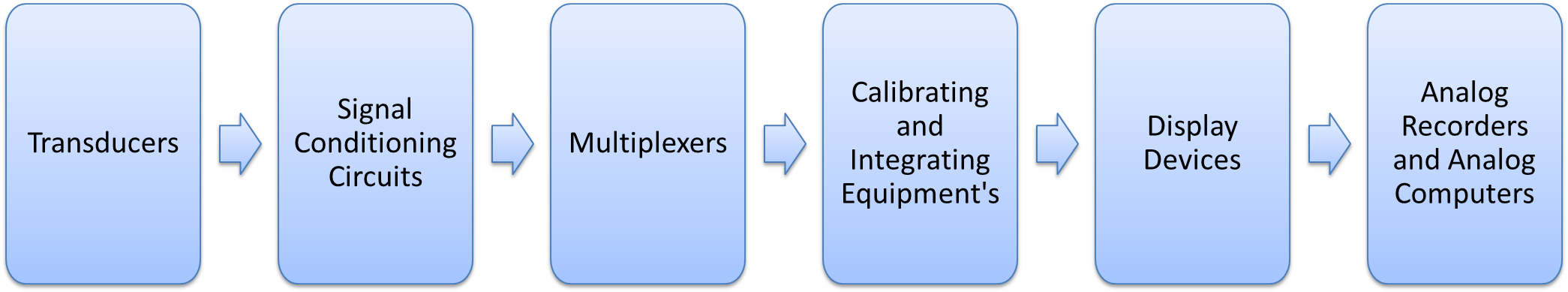

Figure 1: Block Diagram of Data Acquisition System.

The block diagram of analog data acquisition system is as shown in figure 1. Data acquisition systems are used to measure and record analog signals that originate in two ways. The signals like a.c or d.c voltages, frequency, resistance etc, that originate from direct measurement or the signals that originate from the transducer. Basically analog data acquisition systems consist of transducers, signal conditioning equipments, multiplexer, calibrating equipment, integrating equipment, display devices, analog recorders and analog computers

Transducers

The transducers convert the physical quantity to be measured into electrical form. The output signal of the transducer i.e., e.m.f is proportional to the physical quantity being measured. The transducers which are widely used in data acquisition systems are strain gauge, piezoelectric devices, photosensitive devices, thermocouples etc.

Some transducers produce frequency as an output, which is counted with the help of an electronic counter. It gives the integral of the physical quantity being measured, else the voltage is modulated and reduced a demodulator or discriminator.

Signal Conditioning Circuits

Signal conditioners are the devices which convert the output of the transducer into a desired magnitude. It transforms the signal based upon the requirements of the next stage. For proper and smooth operation of the transducers, it also produces the required and appropriate conditions. Some examples of signal conditioners are,

- Zero balanced bridge for strain gauge

- Constant voltage source for strain gauge

- Voltage amplifiers

- Servo mechanism

- Temperature control devices for thermocouple junctions.

Multiplexers

As the name suggests, these devices share the single channel with many outputs. It can accept multiple analog inputs and connects them sequentially. These devices are widely used where the more number of quantities using as single channel are to be transmitted and the distance between transmitter and receiver is large. As single transmission channel is shared by many inputs, the installation cost is low and the device can be maintained for longer duration.

Calibrating and Integrating Equipments

The signals are calibrated and integrated for the transmission to the next stage. The signal is calibrated before performing the test i.e., pre-calibration and also after performing the test i.e., post-calibration. It involves the calibration of all the input circuits called millivolt calibration and calibration of all the bridge-type transducer circuits called shunt calibration. Integrating devices are used for integrating or summing a quantity. For a qualitative test of determining the time integral of a quantity, analog integrating circuits are used. They have the possibility of overloading and low accuracy Therefore, certain digital techniques are adopted for integration process.

Display Devices

Devices for visual displaying are needed for prolonged monitoring of the input signals. The devices are cathode ray oscilloscope (single or multi channel), storage CRO, panel meters, numerical displays etc.

Analog Recorders and Analog Computers

The data from the visual display devices should be recorded and stored. The analog recorders consist of X-Y recorders, strip chart recorders, magnetic tape recorders; CROs with photographic equipment, Duddell’s oscillograph etc.

Analog computers are used to reduce the analog data after it is recorded. This is necessary because the purpose of data acquisition system is not only to record and store the data but also to reduce it into the desired form.

Types of Data Acquisition System

Data acquisition systems are used to measure and record analog signals that originate either from the transducers or from the direct measurement of electrical parameters. Generally; data acquisition system is of two types. They are,

- Analog data acquisition system

- Digital data acquisition system