Dehumidifiers are used to decrease the moisture content or humidity of air. Dehumidification may be accomplished with the help of an air washer system or by using chemicals.

(a) In the air washer system, the outside or entering air is cooled below its dew point temperature, so that, it loses moisture by condensation. The cooling medium i.e. spray water is chilled water and its temperature is lower than the dew point temperature of the entering air. The air leaving the air washer gets cooled and has its dry bulb temperature much below the desired temperature in the room. Therefore, a heating coil is placed after the air-washer, so as to bring the air to desired temperature.

(b) Dehumidification may also be achieved by using chemicals, which have the capacity to absorb moisture in them. Two types of chemicals known as absorbents (such as calcium chloride) and adsorbents (such as silica gel and activated alumina) are commonly used for this purpose.

Types of dehumidifiers

The different types of dehumidifiers are,

- Cooling coil type dehumidifier.

- Spray type dehumidifier.

- Rotary chemical type dehumidifier.

Cooling Coil Type Dehumidifier

It has refrigeration system just like room air conditioner. Mainly it consists of an air filter, fan to draw air and evaporator (cooling coil). The fan provided draws the air from the room through a filter provided. The filtered air is then passed over the evaporator coil, which is maintained at a temperature below the dew point temperature of air. As the air is cooled below its dew point temperature, the moisture gets condensed, dehumidifying the air. The condensate extracted (water) is sent to the condensate drain. A humidistat is provided at the outlet of dehumidifier to check humidity.

Spray Type Dehumidifier (Air Washer System)

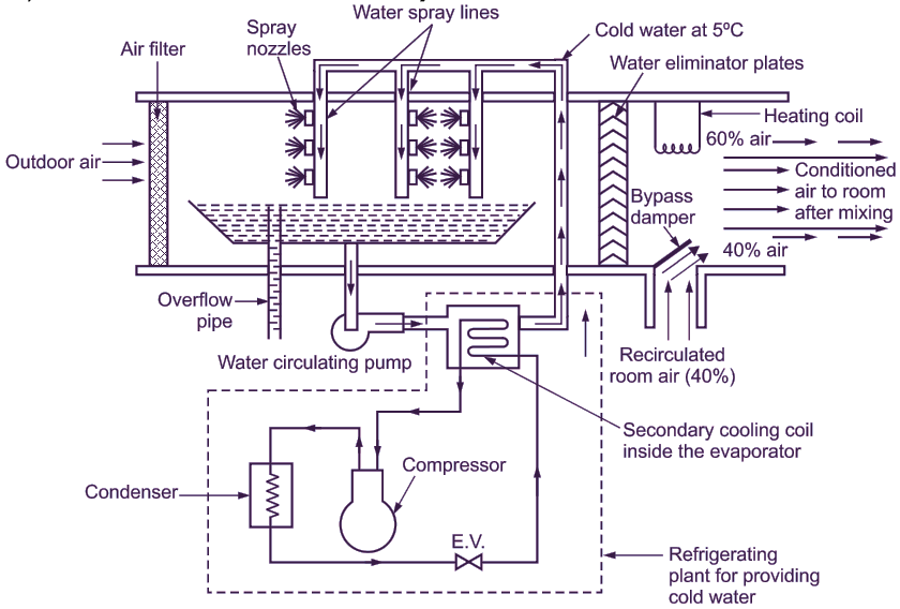

The main components are air filter, water circulating pump, water spray lines, heating coil, humidistat, fan and refrigerating plant for providing cold water having temperature below the dew point temperature of humid air (Figure 1). This system is also called as air washer system. The air is filtered by means of a filter provided at the inlet of dehumidifier. When the humid air comes in direct contact with cold water sprayed by air-washer system, it gets cooled below its dew point temperature, leading to condensation of water vapours associated with it. Thus, the air loses its moisture, i.e. air gets dehumidified. Note that, a refrigerating plant comprising of compressor, condenser, expansion device and evaporator is used to provide cold water having temperature less than dew point temperature of air to be conditioned. This cold water having approximated 5°C is sprayed by air washer system. Water droplets carried by air (if any) are removed in water eliminator. As the air is cooled to much lower temperature than desired, it is passed over the surface of heating coil, where dry bulb temperature is increased to desired level. Amount of this conditioner air is approximately 60% of total supply air, which mixes with the 40% recirculated room air and after mixing, the conditioned air is sent to room. Humidistat can be provided at the outlet to check humidity.

Fig. 1: Spray type dehumidifier

Rotary Chemical type Dehumidifier

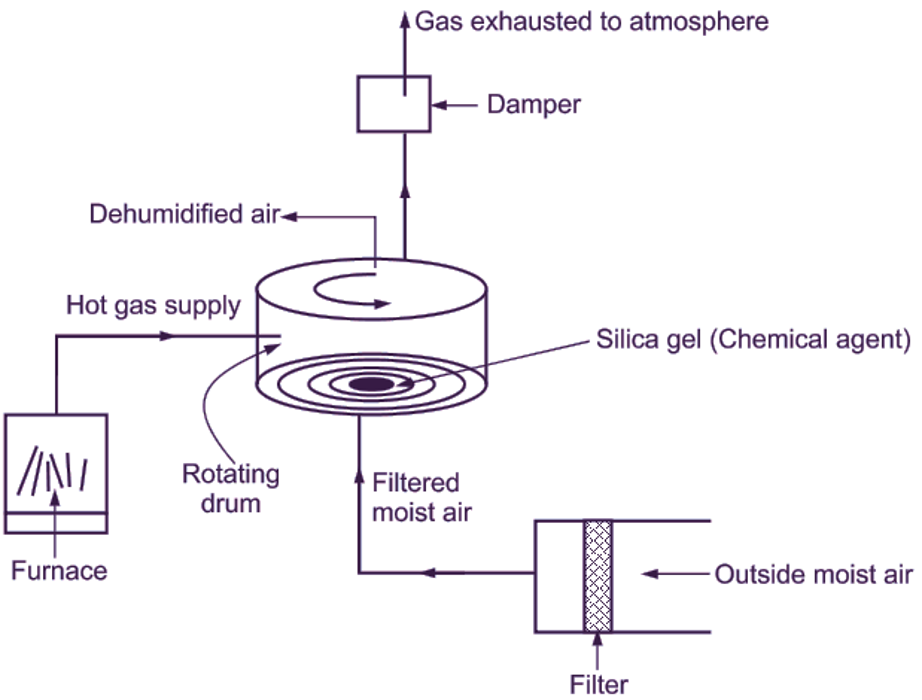

Dehumidifiers are used in variety of industries, where moisture control is absolutely essential. For example Textile, Pharmaceutical, Food and Electronic industries. Fig. 2 shows rotary bed dehumidifier of chemical type. In this dehumidifier, outside air passes through a filter, where contaminants like dirt, dust are removed. This filtered moist air then enters a rotary bed. The rotary bed contains chemical agent such as silica gel, which absorbs moisture on its surface, thereby dehumidifying the air. At the same time, air is heated by using hot gas coming out of a furnace. This helps to achieve the desired temperature of air. Then, the gases are exhausted to the atmosphere by using a damper. The dehumidified air is supplied to the application, where it is required. The moisture absorbed in the silica gel is removed by the reactivation process. It is done by heating the silica gel bed.

Fig. 2: Rotary bed dehumidifier of chemical type

Advantages of Chemical Type Dehumidifier

- It can give continuous operation.

- Huge capacity range.