Humidifiers are the equipments of air conditioning, which are used to increase the moisture content or humidity of air. The process of humidification is done by,

- Injecting the steam.

- Evaporating the water.

- Atomizing the water.

- Air washing.

Humidification by Injecting the Steam

Here, the humidification is done by injecting the steam into the flow of air. As soon as the steam is injected, it gets evaporated instantaneously to gaseous state. This leads to increase in relative humidity of air without any appreciable change in its temperature. These types of humidifiers are used, when excess quantity of boiler steam is available or separate steam generator (boiler) is installed.

Advantages of Steam Injection

- Low initial cost.

- Free from harmful impurities.

- Silent in operation.

Disadvantages of Steam Injection

- Carries unpleasant odour.

- Increases the temperature of air.

Humidification by Automizing the Water

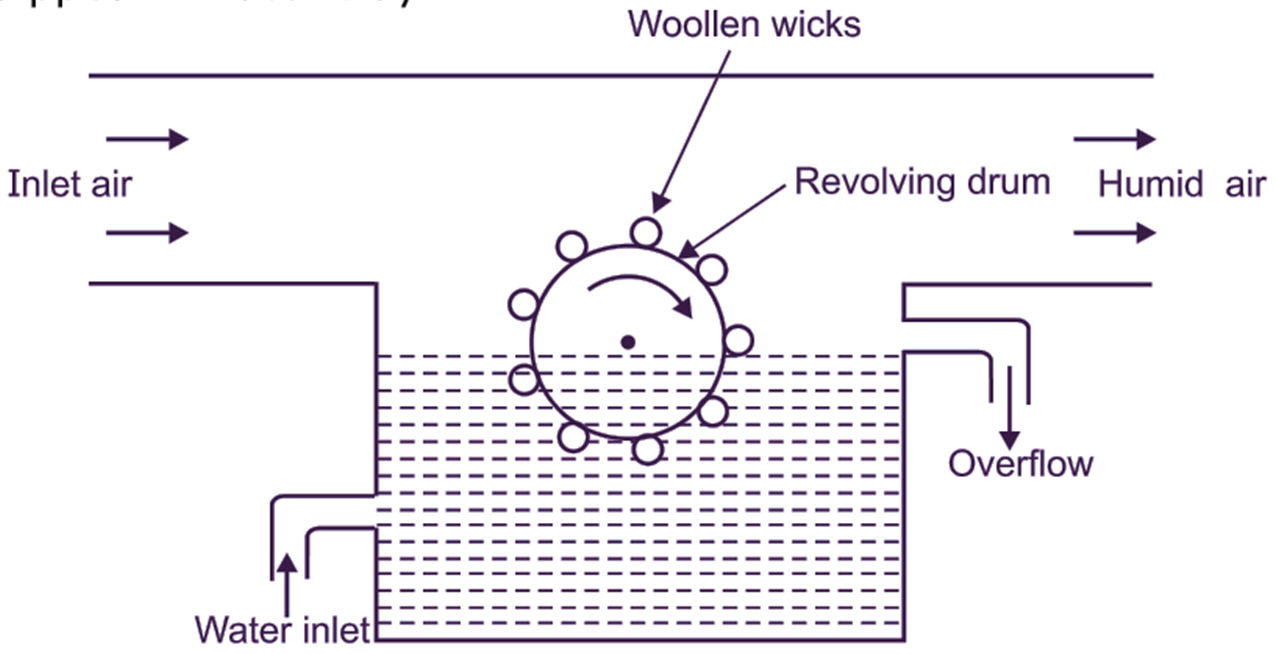

Revolving wicks type humidifier

A revolving drum is placed in the path of air. Numbers of woollen wicks are placed equidistant on the periphery of drum (Figure 1). The lower port-on of drum is always dipped in water tray. The level of the water in the tray is kept constant and is controlled by means of float valve. As the drum rotates, the wetted wicks come in contact with air and water in the wick vapourizes. The water vapours so formed are mixed with air. This is possible because due to rotation of drum, some amount of water is splashed out by the wicks, which atomize the water particles. Thus, the air gets humidified.

Fig. 1: Revolving Wick type humidifier

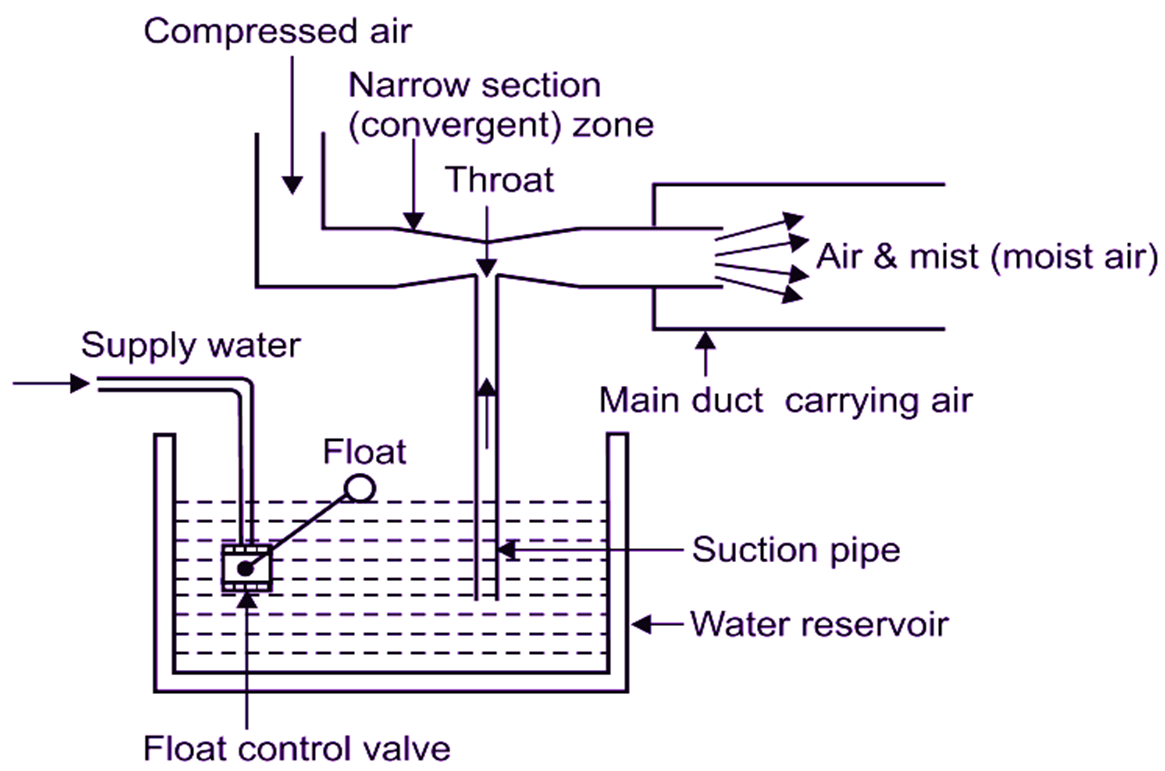

Atomization type humidifier

The compressed air is passed through a narrow section (convergent) of pipe. Due to decrease in flow area, pressure drop is created at the throat (Figure 2). Therefore, water having atmospheric pressure from reservoir is sucked vertically upwards due to pressure difference. In other words, the pressure drop creates suction, which lifts the water from reservoir. The sucked water mixes in the air forming moist air. The humidifier does not add heat in room. The heat required for evaporation of water is taken from the air reducing its dry bulb temperature. Thus, the air gets cooled and humidified. Water level is maintained in the water reservoir by means of float control valve. The float rests on the surface of water level. If the water level goes down, the float will drop with the water level. This will actuate float control valve to supply water to water reservoir, till desired water is achieved.

Fig. 2: Atomization type humidifier

This type of humidifier is generally preferred for industrial purpose, where compressed air is readily available. Compressed air has high velocity and hence high kinetic energy, which further increases at the expense of pressure energy, while passing through convergent zone. Due to high velocity of air, this humidifier is noisy.

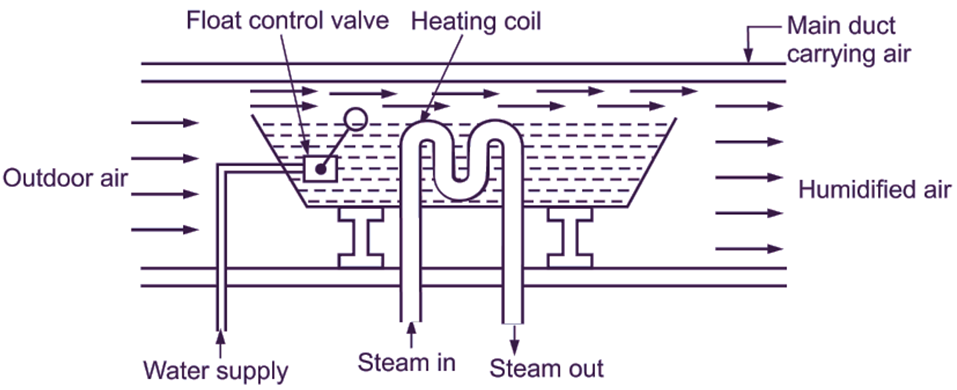

Humidification by Evaporating the Water (Shallow and Pan Coil Type Humidifier)

In this system, when the humidification is required, the heating element in the water pan is energized. The heating device may be electric coil, steam coil or a hot water coil, which warms the water and it leads to evaporation of water to take place on the water surface. Water vapour coming from the water surface is absorbed into the air. The rate of evaporation of water is dependent on the surface area of water exposed to air, flow rate of air and mixing motion. Fig. 3 shows such type of humidifier using steam as a heating medium. A large shallow pan contains water, which is heated by immersing the steam coil. The temperature of the water is controlled by the quantity of steam supplied. The pan is always kept full of water with the help of float control valve. The air is allowed to pass over the water surface as shown in Fig. 3.

Fig. 3: Pan and coil type humidifier

Advantages of Shallow and Pan Coil Type Humidifier

- Simple in operation.

- Maintenance cost is low, as there is no moving part.

Disadvantages of Shallow and Pan Coil Type Humidifier

Close control of relative humidity is not possible with this humidifier, because the water must be heated before humidification starts and must be cooled, before it stops.

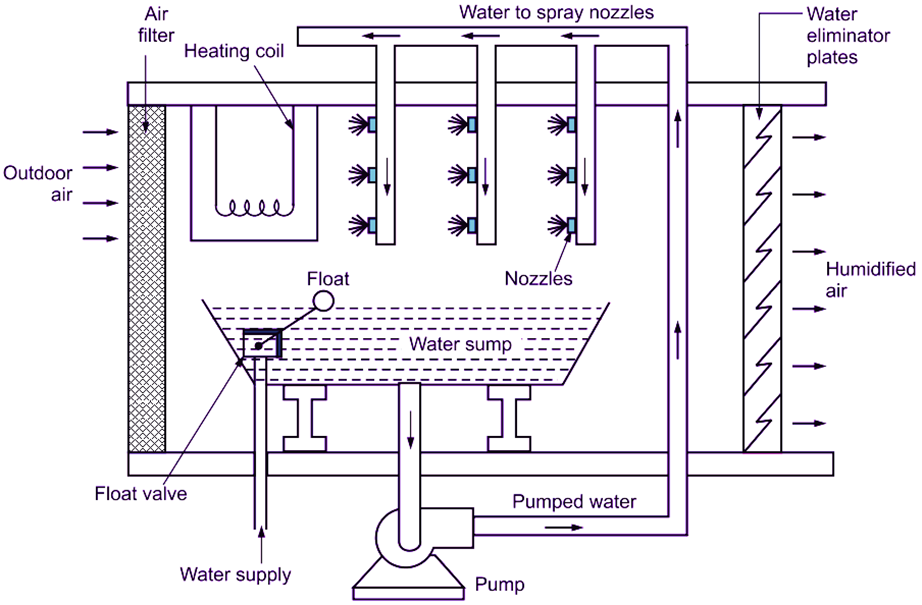

Humidification by Air Washing

This is most effective and commonly used type of humidificaton amongst all. Number of water lines (banks of water sprays) are shown in Fig. 4. These water lines are used for spraying high velocity water jets into the air with the help of nozzles. A small pump supplies the water to the spraying nozzles under high pressure. Due to air washing, the temperature of air decreases. Therefore, a heating coil is placed at the inlet of humidifier. As soon as the water is sprayed in the path of air, some water gets evaporated and it increases the humidity of air due to increase in water vapour content. The on-evaporated water is collected and re-circulated again for humidifcation purpose. A float control valve in supply line controls the level of water in the water sump. Water eliminator plates provided after the sprays remove the water droplets from the air.

Fig. 4: Air Washer type Humidifier

Advantages of Air Washer Type Humidifier

- By regulating the quantity and temperature of water passing through the nozzles, the air can be made to leave the humidifier at any desired temperature and relative humidity.

- As air comes in intimate contact with water, the soluble and objectionable gases will be dissolved in the water leaving the air free from poisonous gases.

- Exact control of relative humidity and temperature can be achieved.

- Easy to operate.

- Low maintenance cost.