In Hartnell governor, movement of fly-balls is controlled by means of a spring. Therefore, Hartnell governor is also known as spring-loaded governor.

Construction of Hartnell Governor

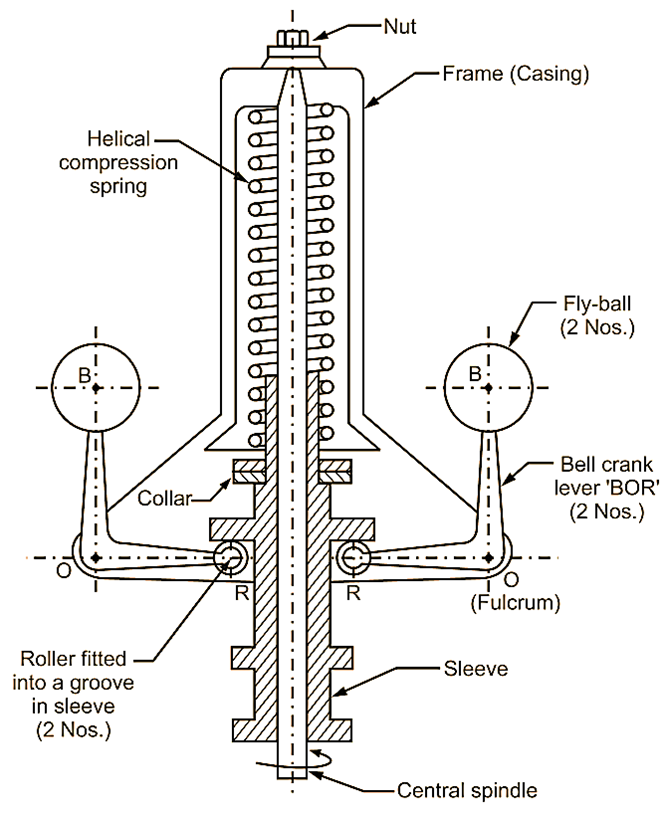

Hartnell governor consists of a casing, in which, a pre-compressed spring of helical compression type is fitted so as to apply force on the sleeve. The sleeve can slide – up and down on the vertical spindle. The casing is keyed to the spindle. Therefore, when the spindle rotates, the casing along with the spring also rotates about the axis of governor. Two bell crank levers are fitted on the frame of casing. Each bell crank lever carries a fly-ball at one end [vertical arm OB] and a roller at the other end [horizontal arm OR]. The rollers fit into a groove in the sleeve. Bell crank levers are pivoted at point ‘O’ to the frame. Therefore point ‘O’ acts as a fulcrum. A helical compression spring exerts equal downward forces on the two rollers through a collar provided on the sleeve. Refer Fig. 1.

Fig. 1: Hartnell Governor

Working of Hartnell Governor

When the load on engine increases

The speed of governor decreases and the fly-balls move inwards, i.e. towards the governor axis. Due to this, the bell crank lever moves about the fulcrum and its roller end lowers the sleeve. This downward movement of sleeve is transferred to throttle valve of an engine through suitable links (not shown in figure), so that, the supply of working fluid is increased in order to increase the speed of governor up to original value.

When the load on engine decreases

The speed of governor increases and the fly-balls move outwards, i.e. away from the governor axis. Due to this, the bell crank lever moves about the fulcrum and its roller end lifts the sleeve against the controlling force. This upward or lifted movement of sleeve is transferred to throttle valve of an engine, so that, the supply of working fluid is decreased in order to decrease the speed of governor up to original value.

Note: Here, the controlling force is spring force along with the weight of sleeve. This spring force can be adjusted by tightening or loosing the nut.