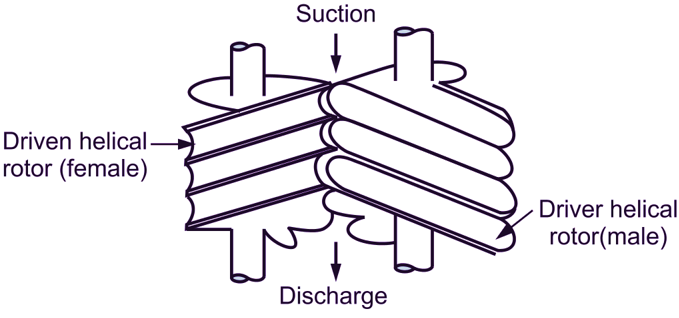

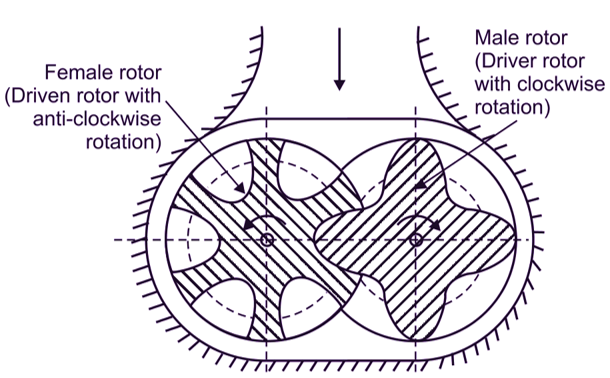

Screw compressor is also called as helical rotary compressor. Screw compressor is displacement compressor, in which, compression of vapour refrigerant is accomplished by two mutually engaged helical grooved rotors enclosed in a casing. The rotor, whose shaft is connected to the motor, is called as male rotor (driving rotor) and the other rotor is called as female rotor (driven rotor). The male rotor consists of a series of lobes (usually four) along its length, which mesh or engage with similarly formed helical flutes (inter-lobes or gullies) usually six on the female rotor.

Fig. 1: Two helical grooved rotors in mesh

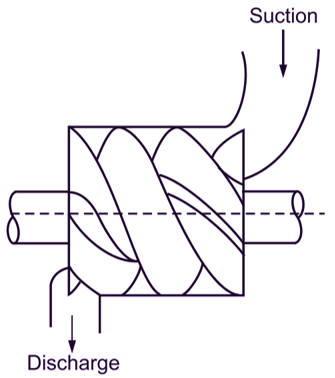

Fig. 2: Screw compressor

Meshing is such that, the lobes projecting or jutting out of male rotor get placed in hollow portion of female rotor. Initially, before this intermeshing, the hollow portion remain filled with gaseous fluid at inlet part. As rotation begins, the surfaces in contact move parallel to the axis of rotors towards the outlet end gradually compressing the vapour refrigerant till the trapped volume reaches to outlet before getting discharged out at designed pressure. As the rotors start to rotate and turn, the vapour refrigerant is sucked through the inlet opening at suction port and gets sealed in the space available between the male lobe and the female flute. This space is also called as interlobed space. As the rotors continue to rotate, meshing of lobes of male rotor and flutes of female rotor starts and progressively reduces the vo ume of the interlobed space, thereby compressing the entrapped vapour refrigerant. Compression of the vapour refrigerant continues, until the inter-lobed space reaches the outlet opening located at the other end of the housing. Finally, the compressed vapour leaves the cylinder (housing) through the outlet opening.

Advantages of Screw Compressors

- High volumetric efficiency.

- Uniform and continuous refrigerant flow is obtained.

- Less power is consumed at partial load.

- Less frictional parts, therefore less wear and tear.

- It can be directly coupled to motor.

- Absence of suction and discharge valve eliminates the pressure drop.

- Less vibrations.

- High mechanical efficiency.

Disadvantages of Screw Compressors

- Very noisy in operation.

- Sensitive to dirt and dust.

- Fragile (i .e. tendency to break) due to small clearances.

Applications of Screw Compressors

- Suitable for applications having refrigerant flow in the range of 200 to 20,000 m3/hour.

- Process refrigeration.