Short tube vertical evaporator is also known as calandria type evaporator and crystallizing evaporator.

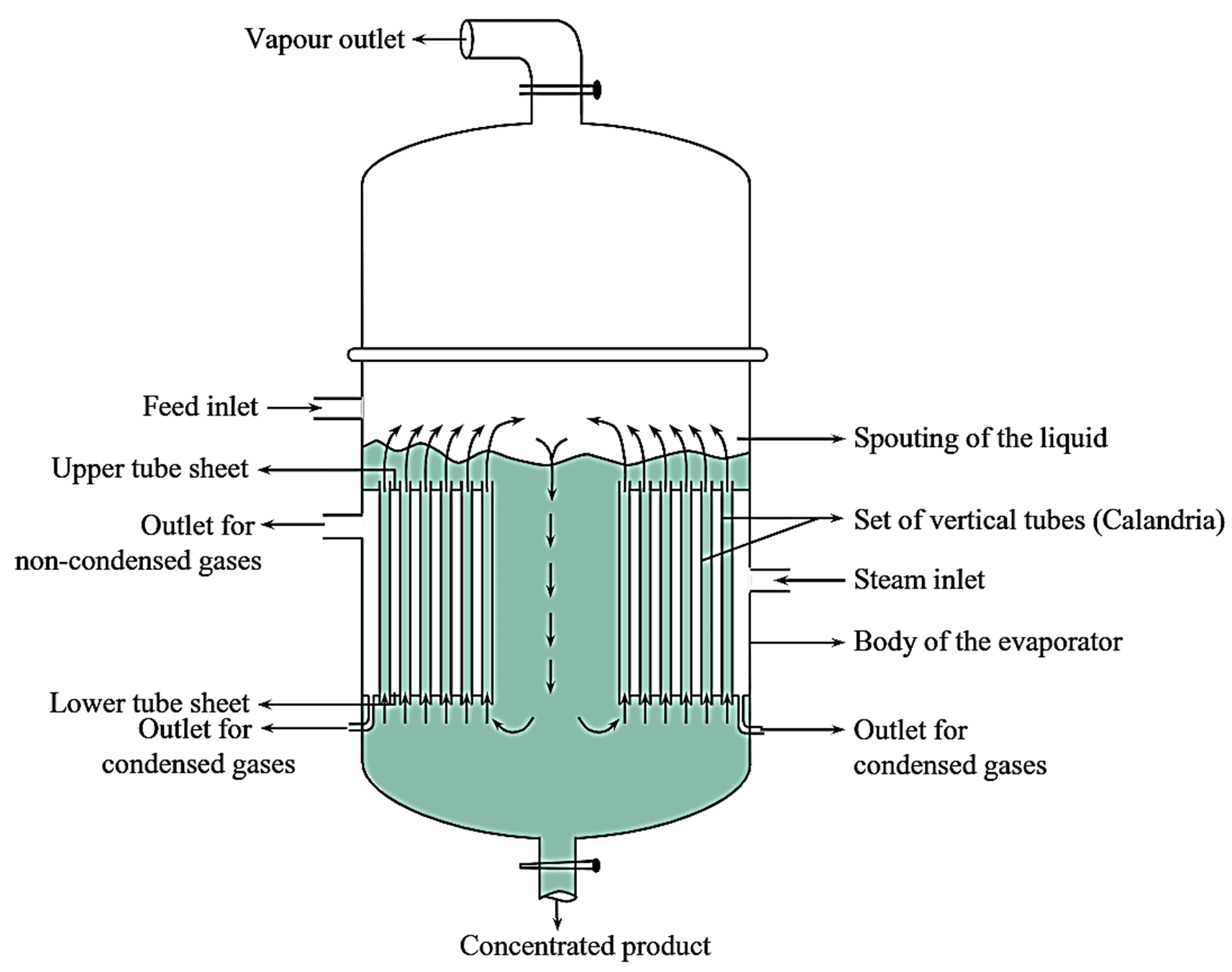

Figure 1: Short Tube Vertical Evaporator.

Working Principle of Short Tube Vertical Evaporator

In short tube vertical evaporator, liquid feed is passed through a set of vertical tubes. The externally supplied steam heats the liquid feed within the tubes which begins to boil. Boiling of the liquid causes it to evaporate. The vapours so formed, are removed from the outlet at the top while concentrated liquid is collected from the bottom of the evaporator.

Construction of Short Tube Vertical Evaporator

Evaporator is cylindrical, dome-shaped and is made up of cast iron. The equipment consists of inlets for feed and steam and outlets for vapour, condensed gases and concentrated product. The body of the evaporator contains a set of vertical tubes (known as calandria) which are 4-6 feet in length and 2-3 inches in diameter. These tubes are held by upper and lower tube sheets.

Working of Short Tube Vertical Evaporator

Liquid feed is introduced through the feed inlet and its level is maintained just above the tubes. Steam supplied through the steam inlet circulates in between the tubes and transfers its heat to the liquid within the tubes. Upon boiling, the liquid moves up through the tubes and then flows down the central compartment. Such movement helps to maintain the circulation of the liquid. The concentrated product formed is collected from the bottom of the evaporator.

Advantages of Short Tube Vertical Evaporator

- Heating surface area is 10-15 times more when compared to the evaporating pan.

- Associated with high heat transfer coefficient (HTC) as it involves continuous circulation of the hot liquid.

- Rate of evaporation can be enhanced by linking the evaporator with a condenser and a receiver.

Disadvantages of Short Tube Vertical Evaporator

- Installation cost of the equipment is high.

- Difficult to clean and maintain when compared to evaporating pan.

- Poor heat transfer when viscous liquids are used.

- The material used for constructing the evaporator body is cast iron, which is not resistant to corrosion.

- Occupies more floor space.

- Boiling point of the liquid is increased, thereby the heat required for evaporation also increases.

- Not suitable for suspensions.

Applications of Short Tube Vertical Evaporator

- It is used in the evaporation of sugar cane juice.

- It is used in the manufacturing of cascara extract, caustic soda, salt and sugar etc.