In this topic, you study Transformer Cooling – Definition & Methods of cooling.

The transformers get heated due to losses (copper and iron) occurring in them. It is necessary to dissipate this heat to the surroundings so as to keep the temperature of the core and windings below the value at which their insulation begins to deteriorate. The cooling methods for transformers are as given below :

Air Natural (AN)

In this method, the transformer core and windings are open to the atmospheric air. The natural circulation of surrounding air is utilized for cooling the transformer by radiation and convection of heat from its surfaces. This method is confined to small transformers only.

Air Blast or Air Forced (AB or AF)

For the large transformers, cooling by natural circulation of air becomes inadequate. Hence, forced circulation of air (i.e. air blast) is employed for this purpose. In this method, using external fans or blowers, the transformer is cooled by a continuous blast of cool air forced through core and windings. Whenever, the temperature rise of the transformer is beyond the permissible limit, provision is made to turn on the fans automatically.

Oil Natural Air Natural or simply Oil Natural (ONAN or ON)

In this method, the heat generated in the core and windings of a transformer is passed on to oil by conduction. Oil then carries this heat to the external surface of the tank using natural convection currents developed in it. Ultimately, the heat is dissipated from the external surface of the tank to the surrounding air. For more effective heat dissipation, the surface area of the tank is increased by providing corrugations, fins, tubes and radiator tanks. This method is commonly used for the transformers upto 5 MVA capacities.

Oil Natural Air Forced (ONAF)

In this method, the oil circulating under natural convection currents transfers the heat to the external surface of the tank. Then the heat dissipation from the tank is made more effective by air blast directed over its external surface. Automatically controlled fans or blowers are used for his purpose. This method is common for medium capacity (upto 10 MVA) transformers.

Oil Forced Air Natural (OFAN)

In this method, oil is circulated from the transformer to the external radiator and back with the help of a pump and is cooled in this external radiator by natural circulation of air.

Oil Forced Air Forced (OFAF)

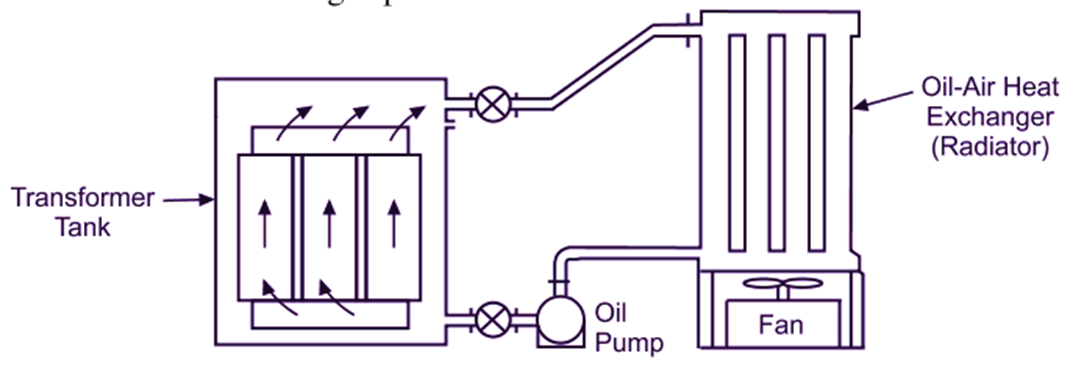

Similar to the above method (OFAN), in this method (Fig. 1) also, oil is circulated from the transformer to the external radiator and back with the help of a pump. But the oil is cooled in this external radiator by using an air blast produced by fans (or blowers). The pump and fans are automatically controlled and are used either separately or in combination as per load on the transformer. This method is common for transformers having capacities above 30 MVA.

Fig. 1: Oil forced air forced (OFAF) cooling

Oil Natural Water Forced (ONWF)

In this method, the heated oil inside the transformer tank is cooled by the circulation of cold water through the copper tubes mounted above the tank but below the oil level. This method has a serious disadvantage that it employs a cooling system which carries water inside the oil tank and therefore is prone to water leakage problems.

Oil Forced Water Forced (OFWF)

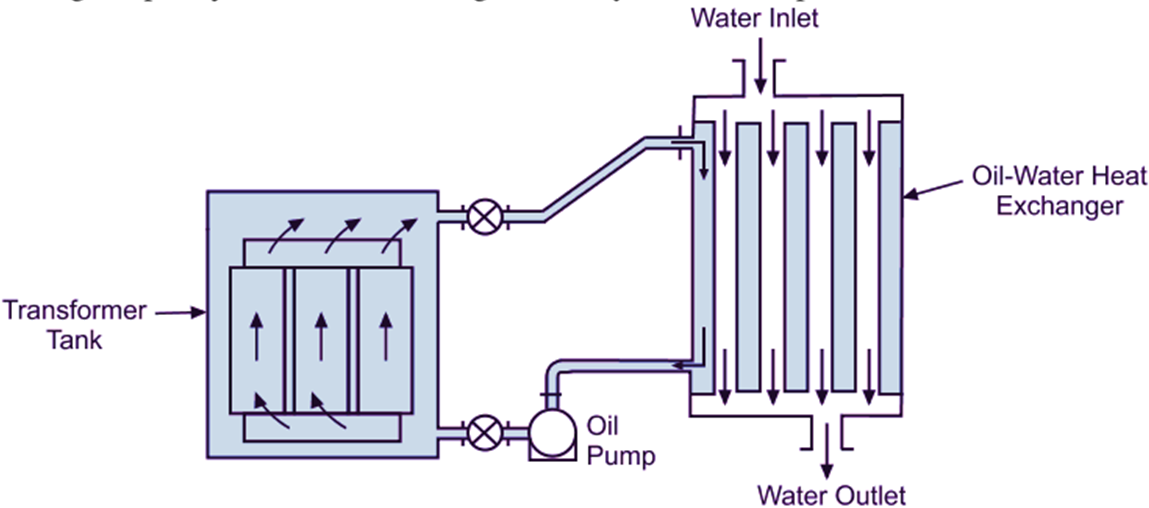

In this method (Fig. 2), heated oil is pumped out from the transformer tank to a heat exchanger (radiator) where it is cooled by cold water passing through the copper tubes. The pressure of oil is kept higher than that of water. Therefore, any leakage that occurs is from oil to water. This system is generally used for the large-capacity transformers designed for hydro-electric plants.

Fig. 2: Oil forced water forced (OFWF) cooling